20 OPP Film Manufacturers in 2024

This section provides an overview for opp films as well as their applications and principles. Also, please take a look at the list of 20 opp film manufacturers and their company rankings. Here are the top-ranked opp film companies as of April, 2024: 1.Cosmo Films, 2.TAN DAI HUNG PLASTIC J.S CO., 3.Jindal Films.

Table of Contents

What Is an OPP Film?

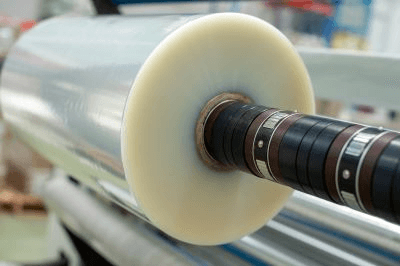

OPP (oriented polypropylene) film is a versatile plastic film made by biaxially stretching polypropylene, a widely used plastic. Known for its excellent transparency, rigidity, moisture resistance, and printability, OPP film is a preferred material in various packaging applications. Despite its lower heat sealability and tear resistance, its benefits make it a popular choice over cast polypropylene (CPP) film, which lacks the superior transparency of OPP.

Uses of OPP Films

OPP film's unique properties make it ideal for:

- Product Packages: Utilized for its protective qualities in retail, enhancing product visibility while ensuring durability during transport and display.

- Food Packages: Chosen for food packaging due to its strength, moisture resistance, and easy-tear features, improving consumer convenience and product freshness.

Principle of OPP Films

OPP film capitalizes on polypropylene's inherent thermal and mechanical robustness, with biaxial stretching enhancing its tensile strength, thermal stability, and moisture barrier properties. This process not only boosts the film's physical attributes but also its optical quality, providing a clear and attractive finish for printed materials.

Other Information on OPP Films

How OPP Film Is Manufactured

OPP film production involves biaxially stretching a polypropylene film first longitudinally and then transversely. This simple yet effective method improves the film's physical and optical properties while maintaining cost-effectiveness by avoiding the need for specialized equipment.

List of 20 OPP Film Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- China

- Germany

- India

- Japan

- Poland

- Taiwan

- United Kingdom

- Vietnam

-

-

-

Toray Plastics

Torayfan OPP

Manufacturer Overview

Toray Plastics is a manufacturer of synthetic fibers, plastics, chemicals, and films founded in 1926. The company is a subsidiary of Toray Industries, Inc. and has two divisions: Toray Plastics America, which is based in North Kingstown, Rhode Island, and Toray Plastics Malaysia, based in Penang, Malaysia. The company operates two manufacturing facilities that produce various synthetic materials including polypropylene film for packaging and capacitor applications, liquid crystal polymers for electronic components and automotive connectors, and polyester-based thermoplastic resins for providing long-term chemical and heat resistance to office equipment. These mainly supply clients in the automotive, automation, and electronic industries.

-

-

-

-

-

D&K Group

Polypropylene (OPP)

Manufacturer Overview

D&K Group, Inc. is an American manufacturer of print finishing products established in 1979 and based in Elk Grove Village, Illinois. The company produces various printing supplies and equipment, such as laminating films, machinery, and adhesives. Its products include wide format or desktop laminators, thermal extrusion as well as pressure-sensitive (cold) laminating films and adhesives, automated high-speed laminating systems, and vacuum- as well as mechanical presses. The company also offers customized machinery, as well as custom adhesives and topcoated products. It mainly serves clients in the packaging, advertising, and medical sectors.

-

-

-

-

-

Cheever Specialty Paper & Film

OPP Film

Manufacturer Overview

Cheever Specialty Paper & Film, established in 1954, is headquartered in Barrington, Rhode Island, USA, and is a manufacturer in the production of customized paper and film products for various industries. The company offers custom-engineered solutions for packaging, labeling, printing, and industrial applications. It has received awards such as the "Excellence in Specialty Paper Manufacturing Award" (2016) and the "Innovation in Film Production Award" (2019). It holds certifications such as ISO 9001:2015 for quality management systems. Its products cater to a broad range of industries, including packaging, automotive, electronics, and medical.

-

-

-

-

-

Griff Paper & Film

Food Grade Films

Company Overview

Griff Paper & Film, established in 1977 and based in Fallsington, Pennsylvania, United States, is a manufacturer and distributor of paper and film products. Their product portfolio encompasses release liners, backing papers, and kraft papers, all of which find applications in adhesives, labels, and packaging. Additionally, they offer a various types of film products, including BOPP film, CPP film, and PET film, catering to needs in food packaging, and medical packaging. Griff Paper & Film also provides an array of other products, including tapes, labels, and custom packaging solutions, to meet specific requirements.

-

-

-

-

-

-

-

-

-

Packaging Made Easy

FDA COMPLIANT CO-EXTRUDED OPP FILM

Distributor Overview

Packaging Made Easy, located in Rancho Cucamonga, California, is a packaging material and equipment supplier since 2005. The company's products include flow wrappers, materials, and accumulation tables to enable pharmaceuticals, cosmetics, medical devices, and food &beverage industries to streamline packaging processes, increase productivity and bottom line. It also offers sustainable packaging solutions that allow companies to minimize environmental footprints without compromising product functionality. Also, the company provides diverse services, including customer support throughout design and production.

-

-

-

-

-

RTG Films, Inc.

POLYPROPYLENE FILM

Distributor Overview

RTG Films, Inc. is a distributor of flexible packaging films established in 1995 and based in Chalfont, Pennsylvania. The company's product inventory includes various polypropylene (OPP) films, vacuum skin packaging (VSP) that work with manual or automatic skin packaging machines, printed or laminated films that can be color-matched, and custom fully recyclable VSP paperboard trays. Aside from its products, the company also offers contract slitting services for customers with unique project specifications. Its products are primarily used by clients in the floral, food, cosmetics, and pharmaceutical sectors.

-

-

-

-

-

Huizhou Yangrui Printing & Packaging Co.,Ltd

OPP/PET Food Packaging Plastic Film Roll

Manufacturer Overview

Huizhou Yanguri Printing and Packaging Co. Ltd., established in 2014 and located in Huizhou, China, is a manufacturer of food containers, packaging bags, and food products films. The company’s products include aluminum foil zip bags, pet food bags, plastic lunch boxes, and candy packaging films. The company has certifications such as a food grade certificate and an Organization for Standardization certificate. The company holds and uses a brand trademark called YangRui.

-

-

-

-

-

Der Yiing Plastic Co., Ltd.

OPP Film

Manufacturer Overview

Der Yiing Plastic Co. Ltd., established in 1991 and headquartered in Taiwan, is a manufacturer of plastic films for different industries. The company specializes in various types of plastic films, including heat-sealable BOPP Film, BOPE film, and multilayer coextruded film. Its films cater to multiple industries, such as food, electronics, and construction. Its release and protective films find applications in packaging, electronics, and other sectors. The company won the Ministry of Economic Affairs Small Business Innovation and Development Program (SBIR) award in 2018.

-

-

-

-

-

Cosmo Films

OPP Films

Manufacturer Overview

Cosmo Films is an Indian manufacturer of bi-axially oriented polypropylene films (BOPP), polyethylene terephthalate (BOPET), and cast polypropylene (CPP) films established in 1981 and headquartered in New Delhi. The company produces films used for packaging, as well as various laminations for metallized substrates or paper, labels, and industrial applications such as electrical insulation or capacitors. It also offers injection molded or thermoformed containers and synthetic paper designed to be tear- and water-resistant. The company primarily serves clients in the food and beverage, cosmetics, education, and electronics sectors.

-

-

-

-

-

TAN DAI HUNG PLASTIC J.S CO.

LAMINATED WITH OUTSIDE PRINTED OPP FILM

Manufacturer Overview

TAN DAI HUNG PLASTIC J.S CO. is a Vietnamese manufacturer of PP (polypropylene) woven bags and agricultural packaging products established in 1984 and based in Tan Phu, Ho Chi Minh City. The company produces UV treated PP woven materials for aqua barriers or flood control, PP woven bags for rice or feed packaging, leno bags for firewood or agricultural products, and industrial-grade geotextiles. These are primarily used in the agricultural sector, as well as feed and food production industries.

-

-

-

-

-

POLYSTAR MACHINERY CO., LTD.

OPP Film

Manufacturer Overview

Polystar Machinery Co., Ltd. was founded in 1989 in Tainan City, Taiwan, as a manufacturer and exporter of plastic recycling and blown film extrusion machines. The company offers various products, including an air cooled recycling machine, a compact blown film machine, a standard blown film machine, and an ABA 3 layers blown film machine. The products facilitate global plastic producers efficient reprocessing of the in-house post-industrial waste into pellets, offering a straightforward and convenient solution. The company serves various industries, including plastic manufacturing, recycling, packaging, automotive, and consumer goods.

-

-

-

-

-

ScandiSales

Top quality OPP film

Manufacturer Overview

ScandiSales Grafisk is based in Hvidovre, Denmark, and is a manufacturer of various printing supplies that was established in 2007 as a subsidiary of the Danish packaging company Ubro A/S. The company produces specialized printing inks, films, paper, and foils. Its products include lacquers and adhesives that can affect printing clarity or sharpness, cold and hot decorative foils, digital printing substrates, biaxially oriented polypropylene (BOPP) film, and wood-free synthetic paper. The company primarily serves clients in the packaging, food and beverage, cosmetics, printing, and pharmaceutical industries.

-

-

-

-

-

Mitsui Chemicals Tohcello, Inc.

OPP Film

Company Overview

Mitsui Chemicals Tohcello, Inc., established in 1929 and headquartered in Tokyo, Japan, is a manufacturer and supplier specializing in the development of materials, films, and sheets. The company's product portfolio includes packaging solutions, protective films, and industrial films and sheets. These products find applications in various industries, including automobile, healthcare, solar energy, food and beverage, and electronics and information technology. The company provides its products and support services across Japan and the rest of Asia, with facilities in China, Taiwan, Thailand, and Malaysia.

-

-

-

-

-

tbs-pack GmbH

OPP/ CPP SEALING FILM

Company Overview

Tbs-pack GmbH, based in Erftstadt, Germany, is a manufacturer and supplier of packaging films and machines with over 40 years in the technical film industry. The company produces its private label films called Castelli-Film, including PVC fine shrink, polyolefin fine shrink, cling, CPP sealing, and PCR recycling films. It also makes its private label packaging machines called Nero-Pack, which include sealing, filling, over-wrapping, bundling, and labeling machinery. The company also provides contract packaging and other support services like international repair, process control to save costs, replacement of old machines, maintenance, and device testing.

-

-

-

-

-

-

-

-

-

-

-

National Flexible. Company

Flexible OPP Packaging Film

Distributor Overview

National Flexible Company is a British distributor of various laminates and special films established in 1993 and based in Bradford, West Yorkshire. The company offers a wide range of packaging films such as high-gloss and oven-friendly polyester (PRT) films, oriented polypropylene (OPP/CPP) used for food packaging, and compostable/biodegradable environmental films. It also offers thermoformers and tray lidding, stand up pouches, and box wrap. The company also provides print, graphic design, and technical training services for customers needing additional support.

-

-

OPP Film Manufacturer Ranking

*Including some distributors, etc.Ranking as of April 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Cosmo Films |

12.9%

|

| 2 | TAN DAI HUNG PLASTIC J.S CO. |

9.5%

|

| 3 | Jindal Films |

6.9%

|

| 4 | Formel Industries, Inc. |

6.9%

|

| 5 | Huizhou Yangrui Printing & Packaging Co.,Ltd |

6.9%

|

| 6 | Kruś Sp z o.o. Sp K. |

6.0%

|

| 7 | Viking Plastic Packaging, Inc. |

5.2%

|

| 8 | Fujian Yongyuan Printing Co.,Ltd |

5.2%

|

| 9 | ScandiSales |

5.2%

|

| 10 | Cheever Specialty Paper & Film |

5.2%

|

Derivation Method

The ranking is calculated based on the click share within the opp film page as of April 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- Mitsui Chemicals Tohcello, Inc.: 1,058

Newly Established Company

- Fujian Yongyuan Printing Co.,Ltd: 2017 (7 years ago)

- Huizhou Yangrui Printing & Packaging Co.,Ltd: 2002 (22 years ago)

- Der Yiing Plastic Co., Ltd.: 1991 (33 years ago)

Company with a History

- Griff Paper & Film: 1977 (47 years ago)

- Cosmo Films: 1981 (43 years ago)

- TAN DAI HUNG PLASTIC J.S CO.: 1984 (40 years ago)

OPP Film Manufacturers in United States

*Including some distributors, etc.

- Toray Plastics

- D&K Group

- Cheever Specialty Paper & Film

- Griff Paper & Film

- Viking Plastic Packaging, Inc.

- Formel Industries, Inc.

- Packaging Made Easy

- RTG Films, Inc.

Global Distribution of OPP Film Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

8 | 42.1% |

China

China

|

2 | 10.5% |

Taiwan

Taiwan

|

2 | 10.5% |

India

India

|

2 | 10.5% |

Vietnam

Vietnam

|

1 | 5.3% |

Japan

Japan

|

1 | 5.3% |

Germany

Germany

|

1 | 5.3% |

Poland

Poland

|

1 | 5.3% |

United Kingdom

United Kingdom

|

1 | 5.3% |

List of OPP Film Products

50 products are listed.

F Picotupa Co., Ltd.

Extraordinary display effects with excellent freshness and deliciousness as they are SLE-K

40+ people viewing

■ Product overview A functional film that is excellent in preserving the contents. ■ Specifications Gently wrap it and show the outstanding displa...

F Picotupa Co., Ltd.

Excellent breathable fruits and vegetables film / bag V -wrap

■ Product overview It is a film with fine holes to achieve moderate breathability. ■ Specifications Gently wrap it and show the outstanding displa...

F Picotupa Co., Ltd.

Easy to handle and outstanding transparency "dedicated parlor rapping film for flower distribution

■ Product overview It is an OPP film that is easy to handle and outstanding transparency. ■ Ventilation hole specification B-1 ・ The size of the ...

F Picotupa Co., Ltd.

Fruit and vegetable film / bag flower cap sewing machine New Micron (for shipment)

■ Product overview It is an OPP film that is easy to handle and outstanding transparency. ■ Ventilation hole specification C-1 ・ The size of the ...

F Picotupa Co., Ltd.

Excellent breathable fruit and vegetable film / bag flower cap porum

■ Product overview A flower cap with fine holes to achieve moderate breathability. ■ Characteristics Excellent breathability and prevents cut flow...

F Picotupa Co., Ltd.

Green and vegetable film / bag flower cap sewing machine (for stores)

■ Product overview It is an OPP film that is easy to handle and outstanding transparency. ■ Ventilation hole specification C-1 ・ The size of the ...

F Picotupa Co., Ltd.

Excellent breathable fruits and vegetables film / bag New Micron

20+ people viewing

■ Product overview It is a general -purpose bag with fine holes to achieve moderate breathability. ■ Specifications Gently wrap it and show the ou...

F Picotupa Co., Ltd.

Green and vegetable film/bag flower cap (for cutting flowers/stores)

■ Product overview It is an OPP film that is easy to handle and outstanding transparency. ■ Ventilation hole specification C-1 ・ The size of the ...