13 Acrylic Resin Paint Manufacturers in 2024

This section provides an overview for acrylic resin paints as well as their applications and principles. Also, please take a look at the list of 13 acrylic resin paint manufacturers and their company rankings. Here are the top-ranked acrylic resin paint companies as of April, 2024: 1.Allnex GMBH, 2.ChemPoint, 3.Topmatch Chemical Co., Ltd..

Table of Contents

What Is Acrylic Resin Paint?

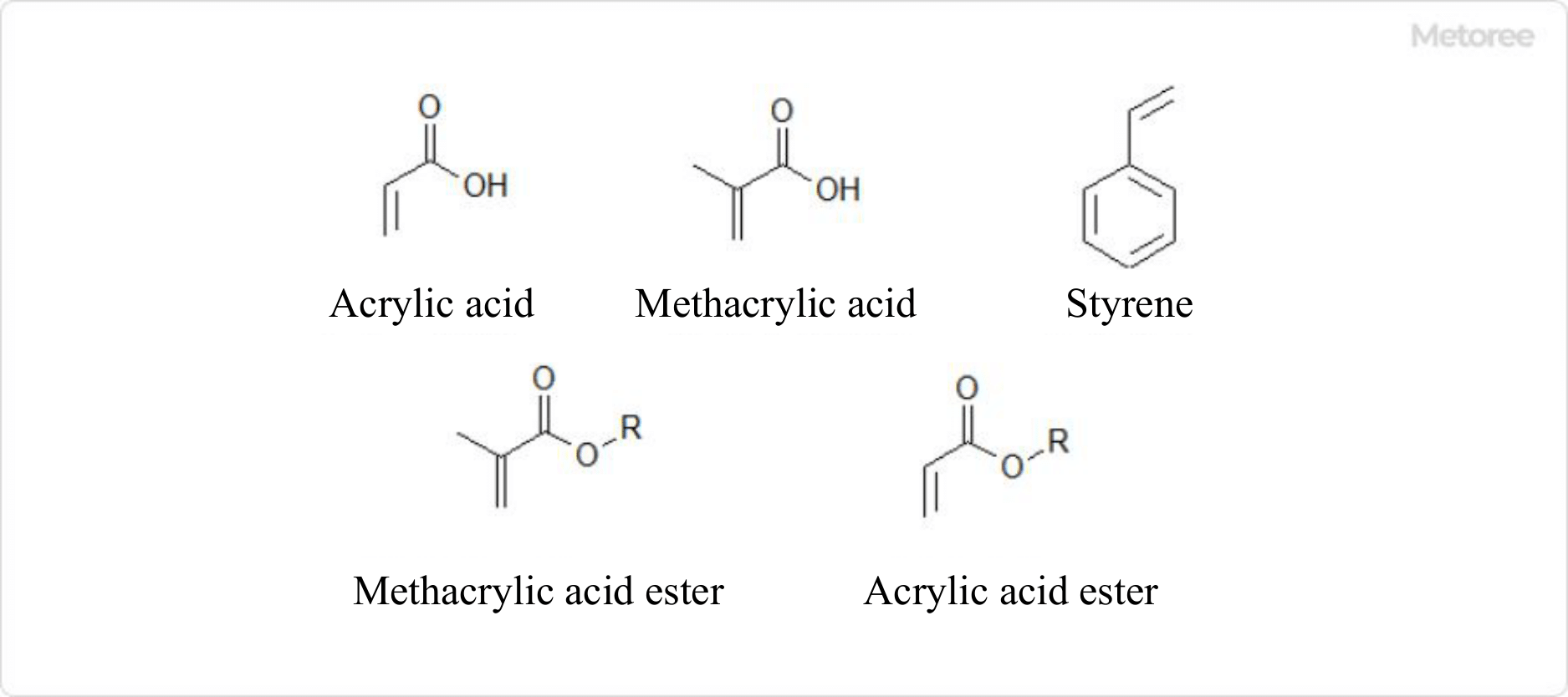

Acrylic resin paint is a type of paint primarily composed of acrylic resin. It was first developed around 1950. Acrylic resin is created through the copolymerization of components like acrylic acid, methacrylic acid, esters, styrene, and other monomers. Due to its versatility in molecular design, acrylic resin is used not only in paints but also in applications such as adhesives and organic glass.

Figure 1. Typical monomers that make up acrylic resins

While acrylic resin paint initially gained popularity due to its excellent color and gloss, it has been largely replaced by higher-performance urethane and acrylic silicone resin paints today. Additionally, concerns about volatile organic compounds (VOCs) have led to a shift from solvent-based paints to water-based paints.

Uses of Acrylic Resin Paints

Acrylic resin paints are still widely used for applications such as exterior wall painting and DIY projects, although their use has decreased with the advent of urethane resin paints. They find application as topcoats on surfaces like concrete, mortar, roof tiles, and PC concrete, both indoors and outdoors.

These paints are also popular in furniture and DIY projects due to the wide range of available colors. Acrylic resins can be tailored to specific applications, resulting in coating films with varying levels of flexibility and hardness by adjusting the type of monomer and degree of polymerization.

Types of Acrylic Resin Paints

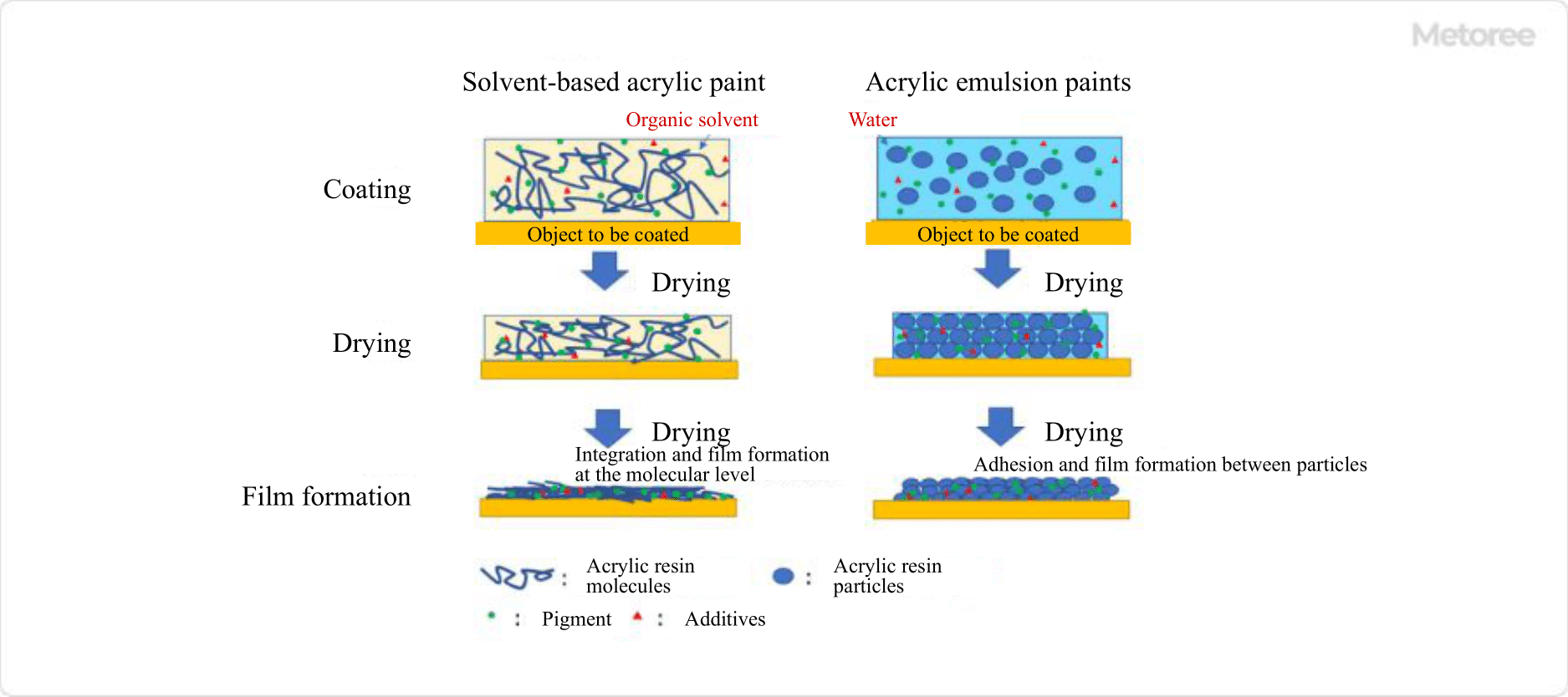

Figure 2. Different mechanisms of acrylic resin paint film formation

There are two main types of acrylic resin paints: solvent-based acrylic paints and water-based acrylic emulsion paints.

1. Solvent-Type Acrylic Paints

Solvent-type acrylic paints are formulated by dissolving the acrylic resin in a thinner, solvent. These paints offer excellent resistance to weather, water, alkali, and oil due to paint film formation at the molecular level. However, they are associated with the odor of the solvent and contain toxic substances.

Given their primary use in construction, consideration must be given to the environment and safety of workers who handle these paints.

2. Acrylic Emulsion Paints

Acrylic emulsion paints, also known as waterborne acrylic resin paints, are produced by emulsifying and dispersing acrylic resin in water. Similar to solvent-based acrylic paints, they can be tailored to enhance functionality. Recent developments have introduced additives such as antiseptic, antifoaming, antifungal, and antifouling agents to improve paint performance.

Acrylic emulsion paints are odor-free and free from damage caused by toxic substances, making them suitable for various architectural applications. Their functionality has expanded with the inclusion of additives, making them increasingly popular.

Additional Information on Acrylic Resin Paints

1. Advantages and Disadvantages of Acrylic Resin Paints

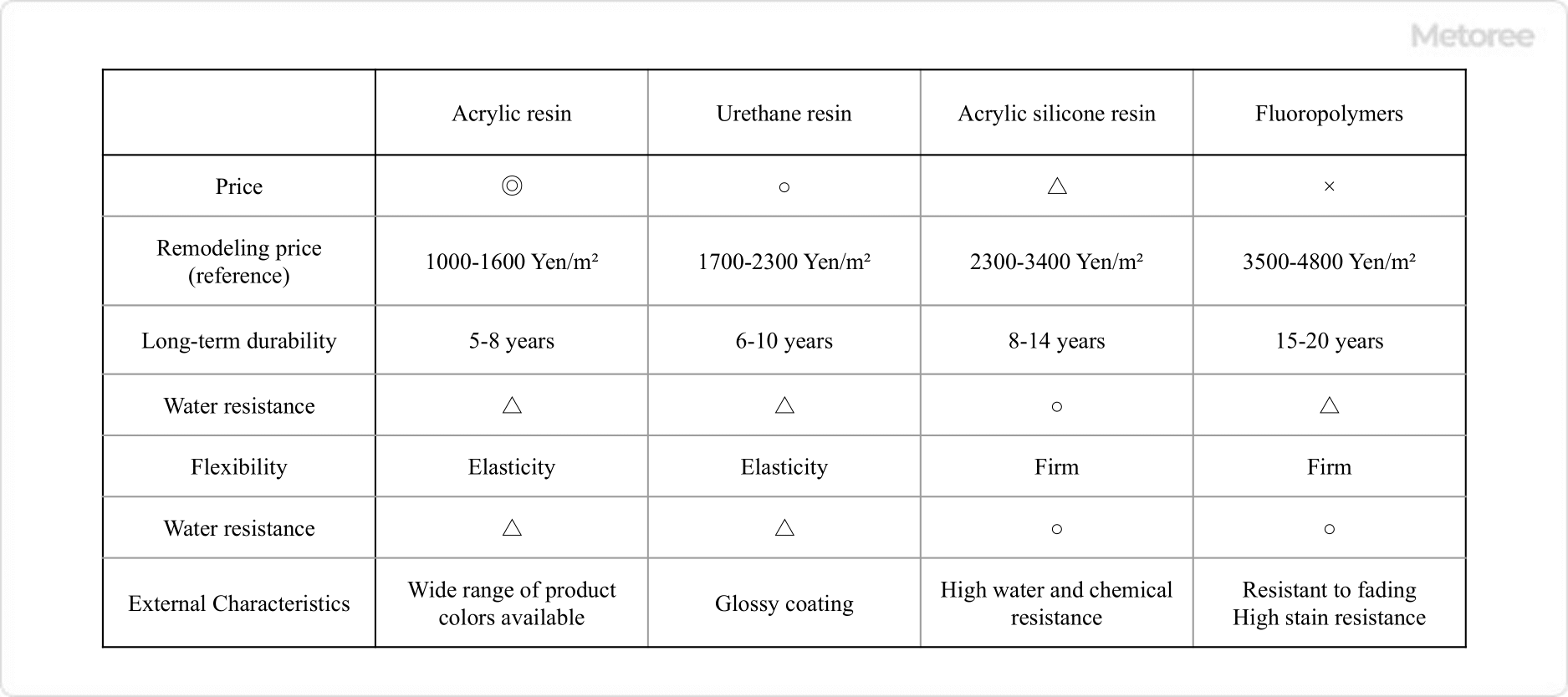

Figure 3. Comparison of characteristics of various paints

The advantages of acrylic resin paints include their affordability, excellent color and gloss, wide color variety, ease of use for amateurs, and suitability for layering. However, they are vulnerable to ultraviolet (UV) rays and degrade relatively quickly due to weathering factors.

UV rays and other environmental factors can cause plasticizers in acrylic resins to gradually decrease, leading to hardening and cracking of the coating film. As a result, the service life of acrylic resin paints is relatively short, typically ranging from 5 to 8 years. Acrylic silicone resin paints, which offer longer service life, have become more common.

Acrylic silicone resin paints incorporate a silicone component into acrylic resin molecules, mitigating the drawbacks of pure acrylic resins. These paints are often used for residential exteriors.

2. Acrylic Resin Paint Manufacturing Process

In general, paints undergo a five-step manufacturing process. Acrylic emulsion paints require additional dispersants and additives compared to solvent-based acrylic paints due to the dispersion of more particles in water-based formulations. Reactive cross-linking agents are sometimes added to increase the strength of the coating film.

- Pre-kneading: Resins, pigments, surfactants, and solvents are mixed to create a particle dispersion (mill base).

- Dispersion: The mill base is dispersed in a dispersing machine until uniform.

- Mixing: Additives and other ingredients are introduced to improve paint performance.

- Filtration: The paint is filtered to remove foreign substances.

- Coloring: Colored paints are mixed with the finished paint to add color. After coloring, each container is filled and shipped.

3. Characteristics of Acrylic Resin Baking Coating

Acrylic resin baking coating involves applying acrylic resin paints to an object and then subjecting the object to heat to thermoset the acrylic resin. This process significantly enhances the strength of the coating film. For acrylic resin, a high temperature of 140°C to 180°C is required for 20 to 30 minutes. Baking coating increases the hardness, scratch resistance, and adhesion of the coating film.

Baked coating improves weather resistance, reducing degradation, fading, and chalking caused by UV rays, which are common weaknesses of acrylic resins. However, baked-on acrylic resin coating may be less flexible and prone to cracking. Therefore, it is suitable for outdoor products.

Other applications include indoor and outdoor furniture, wall coatings, and painting small parts due to its unique characteristics. Examples include vending machines that require weather resistance and accessories that demand colored paints. However, the use of baking coating is limited by the heat resistance temperature of the object to be coated and its size.

List of 13 Acrylic Resin Paint Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- Canada

- China

- Japan

- Netherlands

-

-

-

EMC Fasteners and Tools

Acrylic Enamel Paint & Marking Paint

Manufacturer Overview

EMC Fasteners and Tools, founded in 1966 and based in Michigan, United States, is a manufacturer of various electrical, plumbing, and HVAC products. The company manufactures products in several categories, such as fasteners, electrical, plumbing, tools and accessories, a series of work gloves, and safety products. It manufactures a line of nuts, bolts, washers, screws, and all types of fasteners. It also produces batteries, cable ties, a 4-way stem key, acid brushes, aluminum ducts, outlet adapters, and more. The company serves customers all throughout the United States, including Michigan, Ohio, Indiana, Kentucky, and Illinois.

-

-

-

-

-

Copps Industries, Inc.

Acrylic Resin

Manufacturer Overview

Copps Industries, Inc., established in Mequon, Wisconsin, in 1979 is a manufacturer of epoxy products used in markets such as civil engineering, aggregate/mining, and electrical/electronics. Their product portfolio includes Composite Epoxy Systems, Concrete Coatings and Joint fillers, Construction Epoxies, Machinery Installation Grouts and Wear Resistant and Maintenance Products. Their products find application in sealing joints, filling gaps, laminating, and encapsulating. The company also provides services including Technical Support, national delivery, Quality Control, and customer support.

-

-

-

-

-

Dow Corporate

Acrylic Resin

Company Overview

Dow Inc. was originally incorporated in 1897 and is headquartered in Midland, Michigan. The company is a manufacturer and distributor of numerous advanced materials and chemicals used in packaging, infrastructure, and consumer industries by other companies around the world. The company’s product divisions include Packaging & Specialty Plastics, Industrial Intermediates & Infrastructure, and Performance Materials & Coatings. Packaging & Specialty Plastics include ethylene, rubbers, and wire and cable products. Industrial Intermediates & Infrastructure include ethanol amines, adhesives, sealants, and other composites. Performance Materials and Coatings provides paints and industrial coatings for metal packing.

-

-

-

-

-

Asia Industry Co.,Ltd.

Acrylic resin

Manufacturer Overview

Asia Industry Co., Ltd., established in 1933 with headquarters in Tokyo, Japan, is a manufacturer of architectural coatings, synthetic resins, and other special resins. The company's product line includes acrylic resin, urethane resin, urethane acrylate resin, acrylic-urethane copolymer resin, and acrylic polymer acrylate. These products are used for the manufacture of paints, inks, adhesive products, plastic coatings, and films. The company serves markets that include architectural, consumer product manufacture, construction, packaging, and medical equipment manufacture.

-

-

-

-

-

Topmatch Chemical Co., Ltd.

Hydroxy Acrylic Resin

Manufacturer Overview

Topmatch Chemical Co., Ltd., founded in 1993, has emerged as a industrial paint manufacturer based in China. The company's in-house manufacturing covers a comprehensive spectrum of chemical paints and coatings, utilizing state-of-the-art equipment. The strategic management and workforce have propelled Topmatch to establish itself as a professional paint manufacturer, fostering sustained growth. Notably, Topmatch excels in catering to the industrial machinery sector, providing invaluable services such as color matching technical support, product enhancement, development, and paint consultation. With decades of experience, the company remains at the forefront of the field, benefiting businesses worldwide through its specialized offerings.

-

-

-

-

-

Mitsui Chemicals, Inc

Acrylic resin

Manufacturer Overview

Mitsui Chemicals, Inc was established in 1997 and is a manufacturer and supplier of healthcare, mobility, ICT, and green materials solutions headquartered in Chuo, Tokyo, Japan. The company produces products such as cyclic olefin copolymer, glass fiber reinforced polypropylene, metal integrated molding parts, meltblown nonwoven fabric, and carbon fiber composite material. The products are used in various applications such as automobiles, chemical products, home appliances, construction materials, and water treatments. The company has obtained certificate of ISO 14001 standards.

-

-

-

-

-

Mitsubishi Chemical Corporation

Acrylic Resins for Coating

Manufacturer Overview

Mitsubishi Chemical Corporation was founded in 1933 and has a head office in Tokyo, Japan. Mitsubishi Chemical Corporation provides products including chemicals, industrial gases, and health care products to customers globally. Mitsubishi Chemical Group’s performance products division manufactures and distributes. functional food materials, electronic and electrical components, specialty chemicals, and other products. Mitsubishi Chemical health care products include pharmaceuticals, drug discovery solutions, diagnostic reagents, and instruments for medical use. Mitsubishi Chemical Corporation also provides other services such as engineering, information systems, logistics, and consulting.

-

-

-

-

-

Nouryon

acrylics manufacturing

Manufacturer Overview

Nouryon has a history dating back to 1646 Sweden but was officially formed in 2018 after gaining independence from AkzoNobel. The company is a manufacturer of everyday consumer products including personal care and cleaning goods, as well as products for the agricultural, pharmaceutical, and building industries. The company’s brands include Dissolvine, Witbreak, Butanox, and Ferrazone. These brands manufacture products across five product segments: Bleaching and Oxidizing Chemicals and Technologies, Specialty Polymers, Surfactants and Chelating Agents, Polymer Production and Processing Chemicals, and Specialty Chemicals and Intermediates.

-

-

-

-

-

DIC CORPORATION

Acrylic Resin

Manufacturer Overview

DIC, established in 1908 in Japan, is a manufacturer and supplier of printing inks, organic pigments, and PPS compounds. The company's product portfolio includes different printing inks, such as offset inks used for quality printing, gravure inks for packaging materials, and UV-curable inks for various applications. They also offer organic pigments used in automotive coatings, and PPS compounds, used in electronic and automotive components. DIC's products are used in industries like automotive, electronics, food, and housing. They provide quality products and services that meet societal needs while addressing local and global challenges.

-

-

-

-

-

Protek Paint Ltd.

Protek Acrylic Water Based Paints

Company Overview

Protek Paint is a Canadian manufacturer of paint and coating products, established in 1950, initially manufactured Alkyd Resins used to make paint for home and light industrial applications. The company offers a wide range of products, including wall texture products, consumer products, paint products, supplies and sundries, and tools. They also provides services such as custom color matching, custom manufacturing, and toll manufacturing. They have a strong presence in the industry and have formed partnerships with other companies. For example, they are the North American distributor for CoverIt, which manufactures decorative lime plasters.

-

-

-

-

-

Dryvit Systems, Inc,

Silstar Pro

-

-

-

-

-

Allnex GMBH

Thermoplastic Acrylics

Company Overview

Allnex GMBH, with a corporate heritage dates back to 1948, is a global manufacturing company that specializes in the production of industrial coating resins, crosslinkers, and additives, eadquartered in Frankfurt am Main, Germany. The company offers an extensive portfolio of products, including innovative liquid resins and additives, radiation-cured and powder coating resins, and crosslinkers for use on multiple surfaces such as wood, metal, and plastic. They operate 33 different manufacturing facilities and 23 research and technology support centers around the globe, with 5 joint ventures in Asia.

-

-

-

-

-

ChemPoint

VERSALOID Flexible Acrylic Resin

Distributor Overview

ChemPoint, established in 1999 and a subsidiary of Univar Solutions Inc., is a fine and specialty chemical distributor headquartered in Bellevue, Washington. The company runs ChemPoint, a personalized e-distribution platform that enables the marketing and sales of specialty and fine chemicals in North America, Europe, the Middle East, and Africa. The platform features MarketConnect, a web-based tool that offers market transparency to customers and allows producers to review sales processes. ChemPoint offers a diverse range of specialty chemical products, including adhesives, lubricating fluids, polymers, sealants, and thermoplastics.

-

-

Acrylic Resin Paint Manufacturer Ranking

*Including some distributors, etc.Ranking as of April 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Allnex GMBH |

13.1%

|

| 2 | ChemPoint |

11.7%

|

| 3 | Topmatch Chemical Co., Ltd. |

10.9%

|

| 4 | Copps Industries, Inc. |

10.2%

|

| 5 | Dow Corporate |

9.5%

|

| 6 | Nouryon |

8.0%

|

| 7 | Asia Industry Co.,Ltd. |

8.0%

|

| 8 | Protek Paint Ltd. |

7.3%

|

| 9 | EMC Fasteners and Tools |

5.8%

|

| 10 | Mitsui Chemicals, Inc |

5.1%

|

Derivation Method

The ranking is calculated based on the click share within the acrylic resin paint page as of April 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- Mitsubishi Chemical Corporation: 42,127

- DIC CORPORATION: 22,743

- Mitsui Chemicals, Inc: 18,780

Newly Established Company

- Mitsui Chemicals, Inc: 1997 (27 years ago)

- EMC Fasteners and Tools: 1966 (58 years ago)

- Mitsubishi Chemical Corporation: 1933 (91 years ago)

Company with a History

- Mitsubishi Chemical Corporation: 1933 (91 years ago)

- Asia Industry Co.,Ltd.: 1933 (91 years ago)

- EMC Fasteners and Tools: 1966 (58 years ago)

Acrylic Resin Paint Manufacturers in United States

*Including some distributors, etc.

Global Distribution of Acrylic Resin Paint Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

4 | 40.0% |

United States of America

United States of America

|

3 | 30.0% |

China

China

|

1 | 10.0% |

Netherlands

Netherlands

|

1 | 10.0% |

Canada

Canada

|

1 | 10.0% |

List of Acrylic Resin Paint Products

3 products are listed.

Takase Painting Co., Ltd.

Exterior wall waterproof material clear plus

30+ people viewing

■ Transparent acrylic resin emulsion to prevent rainwater from entering the tiled outer wall ・ The coating of highly transparent acrylic -resin -r...