10 Digital Differential Pressure Gauge Manufacturers in 2024

This section provides an overview for digital differential pressure gauges as well as their applications and principles. Also, please take a look at the list of 10 digital differential pressure gauge manufacturers and their company rankings. Here are the top-ranked digital differential pressure gauge companies as of April, 2024: 1.Instrukart, 2.ACE Instruments, 3.PRISMA INSTRUMENTS & GAUGE BOURDON FRANCE.

Table of Contents

What Is a Digital Differential Pressure Gauge?

A Digital Differential Pressure Gauge is a device that measures and digitally displays the difference in pressure between two points.

It is sometimes called a manometer. The main features of a Digital Differential Pressure Gauge are its simplicity, which allows differential pressure to be measured simply by connecting the two points to be measured with a measuring tube, and its small size and light weight. Many products are available for both gases and liquids.

They can be used for a wide range of applications, from relatively large differential pressure, such as air pressure in air conditioning equipment, to small differential pressure in clean rooms, and can also be used for a wide range of ranges and resolutions. The battery-powered type, which does not require wiring, is used for monitoring and recording equipment, while the type with an alarm device is used for maintenance such as filter replacement. Some of them can measure flow rates using pitot tubes.

Applications of Digital Differential Pressure Gauge

Digital differential pressure gauges are used in a wide range of applications due to their broad measurement resolution. Typical applications are as follows

1. Performance Check of Air Conditioning Equipment

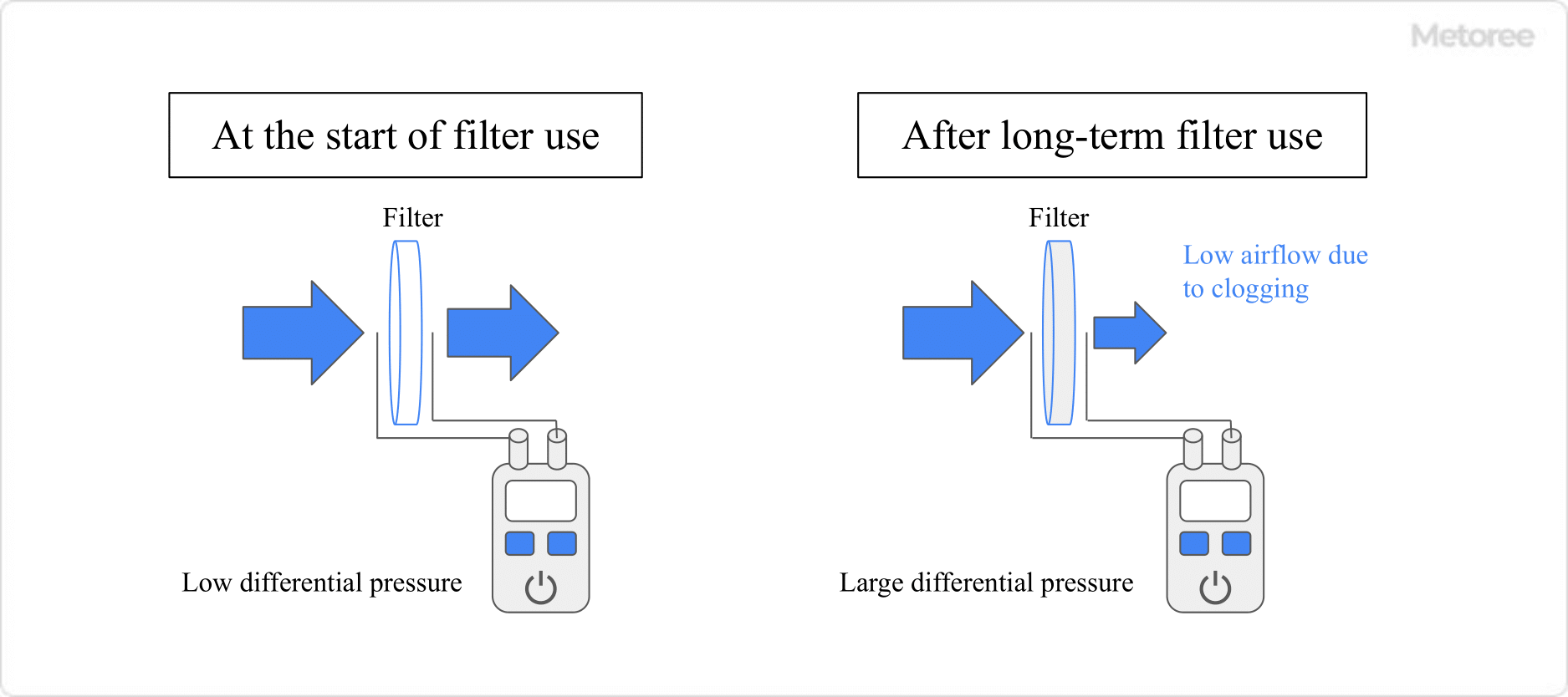

Figure 1. Maintenance of filter deterioration

Air conditioning equipment includes ducts, fans, and filters. As shown in Figure 1, the performance of filters deteriorates due to clogging after long-term use.

As clogging of the filter progresses, the differential pressure before and after the filter increases, so the performance of the filter can be checked using a differential pressure gauge.

2. Environmental Measurement in a Clean Room

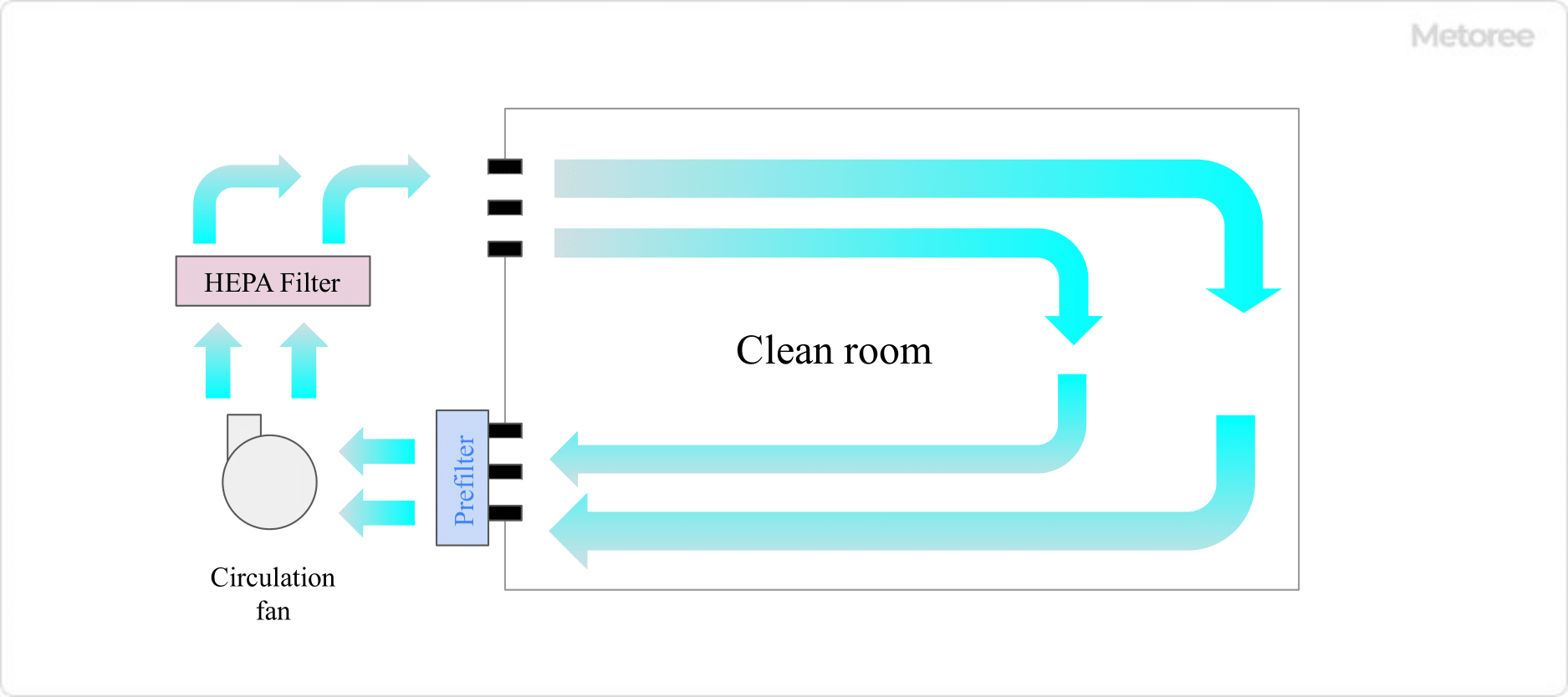

Figure 2. Schematic diagram of a clean room

In a clean room, it is important to maintain air cleanliness. Air is constantly circulated, and filters are used to remove dust and other particles to maintain cleanliness. It is important to check the performance of the filter using a differential pressure gauge.

The inside of the clean room is kept at positive pressure (higher than 1 atmospheric pressure) to prevent dust and other contaminants from being drawn in from outside the clean room. A differential pressure gauge can be used to check whether positive pressure is maintained. Especially when some kind of exhaust system is installed in the clean room, it is essential to check the positive pressure because negative pressure is likely to occur.

3. Level Measurement of Large Sealed Tanks

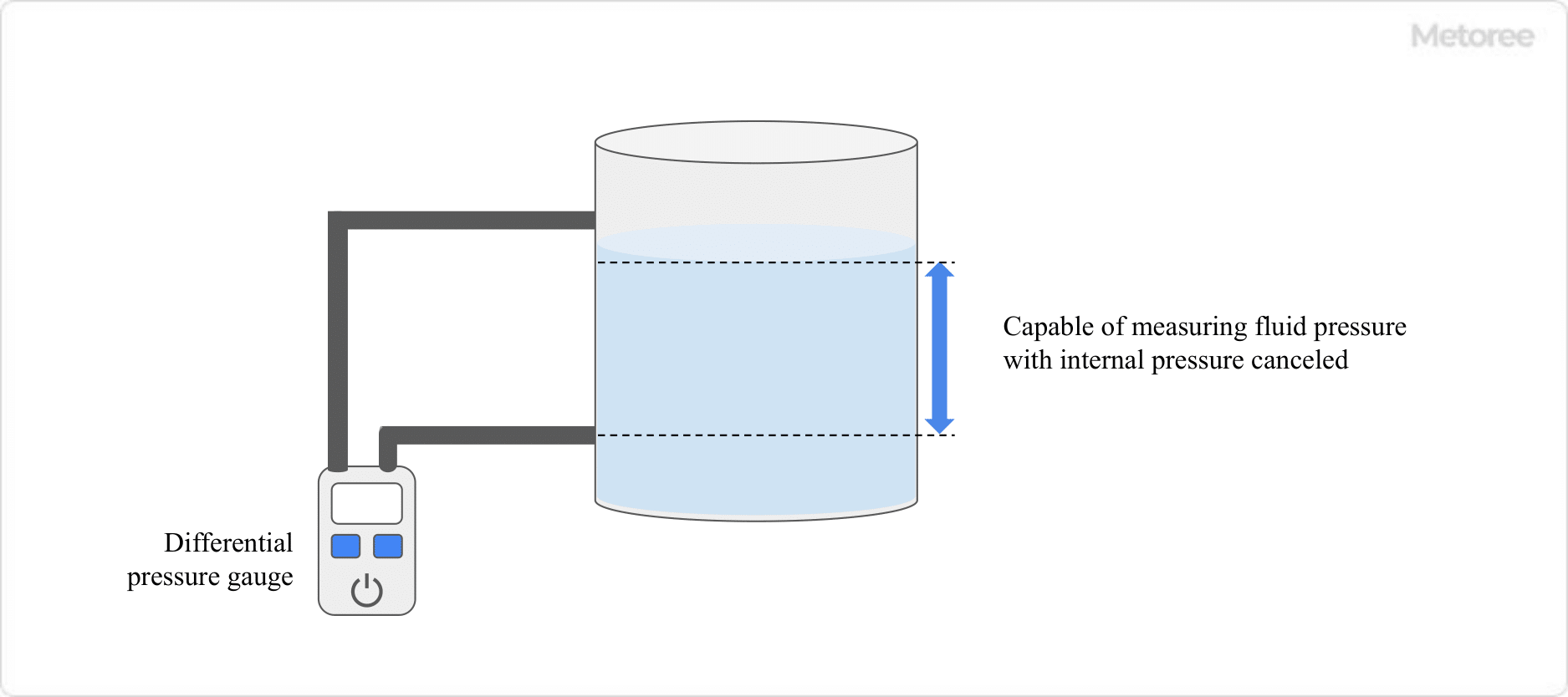

Figure 3. Measuring liquid level height in a sealed tank using a differential pressure gauge

A differential pressure gauge is also used to determine the level (height of the liquid surface) of a liquid in a closed tank. If the specific gravity of the liquid is constant, the pressure applied to the measuring surface is proportional to the level of the liquid, so the level can be determined by measuring the pressure.

However, in the case of a sealed tank, the pressure applied to the measurement surface includes the internal pressure of the tank top surface, so it is necessary to cancel the effect of the internal pressure. In such cases, a differential pressure gauge can be used to measure only the pressure due to the liquid.

Principle of Digital Differential Pressure Gauge

When pressure is applied to a pressure-sensitive element, the deflection of the element is measured as an electrical signal by the change in resistance due to the current flowing through the element. The relationship between the electrical signal and the displacement of the element is used to convert the measurement result into pressure. Digital Differential Pressure Gauge displays the difference in pressure between two points measured in this way as a digital value.

Since the Digital Differential Pressure Gauge has two measuring points, it measures the magnitude and direction of the deflection (displacement) caused by the pressure applied from the two measuring points in two directions. By measuring the direction, it determines which is the high pressure side and which is the low pressure side, and the difference in displacement is read as an electrical signal and displayed as a pressure difference.

Other Information on Digital Differential Pressure Gauge

About the Pressure-Sensitive Element

Embedded inside a Digital Differential Pressure Gauge is a piezoelectric element (piezoelectric element) as a pressure-sensitive element. A piezoelectric element is a passive element that uses the piezoelectric effect to generate a voltage in response to the pressure applied to a specific material. Crystal (synthetic quartz) and ceramics with strong magnetic properties are mainly used.

The piezoelectric element, which is the key to measurement, consists of a piezoelectric material with the piezoelectric effect sandwiched between two electrodes. The simple structure of the piezoelectric element has the advantages of being durable, resistant to deterioration, and lightweight.

There are many materials that possess the piezoelectric effect, and since materials for pressure-sensitive elements are being developed, products that enable more precise measurement are also being developed.

List of 10 Digital Differential Pressure Gauge Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- France

- Germany

- India

- Japan

-

-

-

Omega Engineering, Inc.

DIGITAL PRESSURE GAUGE (DPG) DIFFERENTIAL PRESSURE HIGH 0.08% ACCURACY

Manufacturer Overview

OMEGA Engineering Inc., founded in Norwalk, CT, in 1962 is a manufacturer of products used to measure temperature and humidity, flow and level, and pressure. The company's product portfolio includes thermocouple probes and assemblies, pressure gauges and switches, and air velocity measurement systems, wireless systems and portable optic sensors. The company serves markets including Automotive and Electric Vehicles, Renewable Energy and Energy Storage and Electronics and IT Infrastructure. The company also offers customer services that include support, custom research projects and customized services.

-

-

-

-

-

Sensocon, Inc.

Digital Differential Pressure Gauges & Controls

Manufacturer Overview

Sensocon, Inc., established in 2005 and based in Florida, United States, is a manufacturer of differential pressure, air velocity, and flow products. The company also produces other products, such as digital differential pressure gauges and controls, air flow monitors, airflow probes, and other accessories. Apart from this, the company also offers calibration services for Sensocon products. The company offers products in areas of differential pressure, air velocity, and airflow and other products, including air flow probes and, measuring stations and differential pressure transmitters.

-

-

-

-

-

Testo SE & Co. KGaA

Differential pressure

Manufacturer Overview

Established in 2006, Testo India Pvt. Ltd., a Pune, India-based subsidiary of Testo SE & Co. KGaA, is a manufacturer and supplier specializing in measuring instruments. Complying with the ISO/IEC 17025:2017 standard set by the National Accreditation Board for Testing and Calibration Laboratories (NABL), the company produces measuring instruments for temperature, humidity, pressure, and flow (bulk fluid movement). The company also offers electrical, sound level, and nanoparticle measuring devices. These products are designed for industrial applications with regard to heating, ventilation, air conditioning, and refrigeration (HVAC-R), as well as environmental monitoring technology, in sectors like food service, retail, and pharmaceuticals.

-

-

-

-

Manufacturer Overview

Instrukart, established in 2015 and headquartered in Hyderabad, Telengana, India, is a manufacturer of various industrial process control equipment. The company offers a broad range of products, including clean room monitors, gas detectors, data loggers, IAQ (Indoor Air Quality) monitors, and numerous process control instruments. It holds ISO 9001 certification for meeting rigorous standards and providing accurate and stable measurements. These instruments are invaluable in various industries, including pharmaceuticals, healthcare, manufacturing, and environmental monitoring, where maintaining precise environmental conditions and safety standards is important.

-

-

-

-

-

PRISMA INSTRUMENTS & GAUGE BOURDON FRANCE

PI700X Digital differential pressure gauge 0.05% with Recorder

Manufacturer Overview

PRISMA INSTRUMENTS & GAUGE BOURDON FRANCE, established in 1998 in Aubagne, France, is a manufacturer of industrial instruments and process control equipment. The company’s product portfolio includes pressure gauges, temperature sensors, level measurement devices, and flow meters, serving a wide spectrum of industrial needs. With ISO 9001 certification, it offers precision and stability in the instruments and plays a vital role in industries such as oil and gas, petrochemical, automotive, and manufacturing by providing accurate and real-time data for process monitoring and control.

-

-

-

-

-

Care Instruments

Digital Differential Pressure Gauge

Manufacturer Overview

Care Instruments, founded in 2007 and located in Ahmedabad, Gujarat, India, is a manufacturer of industrial process instruments. The company’s product range covers a wide array of instruments, including pressure gauges, temperature sensors, level indicators, and flow measurement devices. It is ISO 9001:2015 certified for quality and precision, and the products are equipped with accuracy, durability, and stability, which are critical in ensuring smooth industrial operations. It serves various industries, including petrochemicals, pharmaceuticals, power generation, and food processing, providing crucial instrumentation solutions to monitor and control processes.

-

-

-

-

-

NAGANO KEIKI CO., LTD.

GC30 Digital Differential Pressure Gauge

Manufacturer Overview

Nagano Keiki Co Ltd is a company founded in the year 1896 and based in Tokyo, Japan as a manufacturer and supplier of pressure and temperature sensors. Their product portfolio includes digital pressure gauges, pressure and temperature sensors, and digital panel meters in different models. The company also provides effective solutions with calibration and maintenance. The products are used in multiple industries which include automobile, construction, machinery, semiconductors, marine, aeronautical, medical, gas, and energy.

-

-

-

-

-

AMETEK Sensors, Test & Calibration

XP2i-DP Differential Pressure Gauge

Manufacturer Overview

AMETEK Sensors, Test & Calibration, founded in 1961 and based in Massachusetts, USA, is a manufacturer, distributor, and supplier of instruments and process control solutions for advanced manufacturing processes. The company provides a range of standard and customized solutions for various industries such as calibration, temperature measurement, and weighing solutions. Its products are constantly used throughout the oil and gas, power, and wastewater industries, helping to save and produce energy, ensure safety in hazardous areas, and control temperatures.

-

-

-

-

-

VALCOM CO.,LTD.

Digital Pressure Meter

-

-

-

-

-

ACE Instruments

Digital Differential Pressure Gauge(AI-DDPG)

Company Overview

ACE Instruments, established in 1991 in India, is a manufacturing company of specialty process control instruments for pharma, bulk drugs, healthcare and chemicals. The company designs, developes and manufactures of process control instruments, catering to the growing need for superior products with the latest technology, backed up by prompt service support. With its state-of-the-art manufacturing facility at Industrial Estate Kukatpally, Hyderabad, it can customize solutions for the lifesciences, hospitals, HVAC pharma & bulk drug manufacturing facilities including a whole range of clean room instruments, flameproof Instruments and process control instruments.

-

-

Digital Differential Pressure Gauge Manufacturer Ranking

*Including some distributors, etc.Ranking as of April 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Instrukart |

19.6%

|

| 2 | ACE Instruments |

15.7%

|

| 3 | PRISMA INSTRUMENTS & GAUGE BOURDON FRANCE |

11.8%

|

| 4 | Care Instruments |

11.8%

|

| 5 | Sensocon, Inc. |

11.8%

|

| 6 | NAGANO KEIKI CO., LTD. |

9.8%

|

| 7 | Testo SE & Co. KGaA |

9.8%

|

| 8 | AMETEK Sensors, Test & Calibration |

5.9%

|

| 9 | Omega Engineering, Inc. |

3.9%

|

Derivation Method

The ranking is calculated based on the click share within the digital differential pressure gauge page as of April 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- NAGANO KEIKI CO., LTD.: 2,344

Newly Established Company

- Instrukart: 2015 (9 years ago)

- Care Instruments: 2007 (17 years ago)

- ACE Instruments: 1991 (33 years ago)

Company with a History

- NAGANO KEIKI CO., LTD.: 1948 (76 years ago)

- Testo SE & Co. KGaA: 1957 (67 years ago)

- Omega Engineering, Inc.: 1962 (62 years ago)

Digital Differential Pressure Gauge Manufacturers in United States

*Including some distributors, etc.

Global Distribution of Digital Differential Pressure Gauge Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

India

India

|

3 | 37.5% |

United States of America

United States of America

|

2 | 25.0% |

Germany

Germany

|

1 | 12.5% |

France

France

|

1 | 12.5% |

Japan

Japan

|

1 | 12.5% |

List of Digital Differential Pressure Gauge Products

17 products are listed.

SIBATA SCIENTIFIC TECHNOLOGY LTD

Detailed air environment at the dismantling site Measurement differential pressure meter (negative pressure meter) "CHICCO-Iino" FPL-1

Last viewed: 5 hours ago

The FPL-1 is an inexpensive differential pressure gauge. Equipped with negative pressure setting warning functions and data logging functions in ac...

Custom Co., Ltd.

Industrial equipment measuring instrument digital differential pressure meter DPG-01U

10+ people viewing

Last viewed: 5 hours ago

Digital differential pressure gauge with a sophisticated piano black tone. Two air pressure differential pressure measurements are possible.

Krone Co., Ltd.

High -precision digital micro -pressure meter/drip -proof dustproof BOX KS2900

Last viewed: 5 hours ago

■ Overview ・ The digital micro -pressure monitor KS2900 is a model that uses a high control LCD for the display part so that the visibility is hig...

Endress+Hauser Group Services AG

Deltabar FMD78, which measures liquids, gas, steam, and liquid levels and output analog or digital signals

Last viewed: 5 hours ago

Difference transmission device with two diaphragm seals for differential and level ■ Applications Deltabar FMD78, a differential pressure transmis...

Endress+Hauser Group Services AG

Liquid, paste, gas pressure, level, flow pressure measurement device differential pressure transmission device deltabar PMD55

10+ people viewing

Last viewed: 5 hours ago

Difference transmission device equipped with metal sensor for differential pressure measurement ■ Applications DELTABAR PMD55 is a differential pr...

Endress+Hauser Group Services AG

Liquid, paste, gas pressure, level, flow pressure measurement equipment Electrical differential pressure transmission device Deltabar FMD72

10+ people viewing

Last viewed: 5 hours ago

Electrical differential pressure transmission device consisting of two metal sensor mougles and one transmit ■ Applications Electric differential ...

Endress+Hauser Group Services AG

Liquid, paste, gas pressure, level, flow pressure measurement equipment Electrical differential pressure transmission device Deltabar FMD71

Last viewed: 5 hours ago

Electrical differential pressure transmission composition composed of two ceramic sensor journals and one transmit ■ Applications The electrical d...

Endress+Hauser Group Services AG

Liquid, paste, gas pressure, level, flow pressure measurement equipment differential pressure transmission device deltabar PMD75

Last viewed: 5 hours ago

Metal sensor -mounted differential pressure transmission device for differential pressure measurement ■ Applications The Deltabar PMD75 is a diffe...

Endress+Hauser Group Services AG

Deltabar FMD77, which measures liquids, gas, steam, and liquid levels and output analog or digital signals

Last viewed: 5 hours ago

Different pressure transmission with one side diaphragm seal for level measurement ■ Applications The Deltabar FMD77 differential pressure transmi...

Krone Co., Ltd.

Digital manometer EMA84 for differential pressure measurement at maintenance sites

■ Overview EMA84 is a high -performance portable differential digital manometer. The measurement range can be selected from 4 types, the measuremen...

Krone Co., Ltd.

Battery -driven portable digital manometer PS309D / PS309A series

■ Overview ・ It is a small, lightweight battery -driven portable digital manometer. ・ With excellent temperature characteristics, differential pr...

Krone Co., Ltd.

Digital manometer EMA200 for differential pressure measurement at maintenance sites

■ Overview ・ EMA200 is a high -performance portable type differential digital manometer. ・ Measurement range can be selected from 4 types, and me...

Krone Co., Ltd.

Ideal for HVAC applications digital microscopic meter 699M series

■ Characteristics It is a pressure transmitter for serial communication modbus. It is a specification that can measure 2ch with one unit, and can m...