12 Air Plasma Cutting Machine Manufacturers in 2024

This section provides an overview for air plasma cutting machines as well as their applications and principles. Also, please take a look at the list of 12 air plasma cutting machine manufacturers and their company rankings. Here are the top-ranked air plasma cutting machine companies as of April, 2024: 1.Huaheng Automation Pvt. Ltd., 2.S. R. Advantech Systems Pvt Ltd, 3.ANDELI GROUP CO.,LTD.

Table of Contents

Categories Related to Air Plasma Cutting Machines

What Is an Air Plasma Cutting Machine?

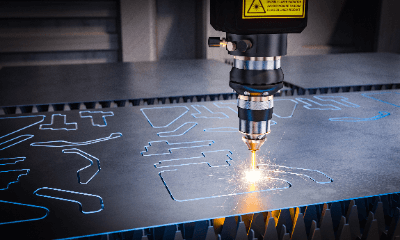

An Air Plasma Cutting Machine is a machine that uses high-temperature arc plasma to cut metals.

An Air Plasma Cutting Machine is a machine that uses high-temperature arc plasma to cut metals.

Because it is a type of plasma cutting machine and uses high-temperature arc plasma, it can cut metals efficiently. Compared to gas cutting machines and plasma cutting machines, they can cut many types of metals, including hard metals such as stainless steel, aluminum, brass, and iron.

They are also widely used in large factories, automobile repair shops, and shipyards. When metals need to be cut, Air Plasma Cutting Machines are essential in many industries because of their high efficiency.

Like plasma cutting machines, they require advanced technology, but when operated correctly, they are efficient.

Safety must also be taken into consideration, and it is important to wear appropriate safety equipment such as safety glasses and gloves during operation.

Uses of Air Plasma Cutting Machine

Air Plasma Cutting Machines are primarily used for cutting metal, mainly in processing plants. Unlike Plasma Cutting Machines, Air Plasma Cutting Machines use high-pressure air and can cut many metals, including hard metals, aluminum, brass, and iron.

They are used for cutting steel frames and steel products, processing metals at construction sites, and cutting metals in automobile and ship repair shops. Additionally, they are widely used in a variety of fields, including pipelines, steel mills, and the aerospace industry.

Air Plasma Cutting Machines, like Plasma Cutting Machines, are used manually and are effective for cutting thick plates, although they are not suitable for finish cutting as the cut surface tends to be somewhat rough.

Principle of Air Plasma Cutting Machine

Air Plasma Cutting Machines are composed of a plasma arc that melts and cuts metal by means of high-temperature arc heat and plasma flow.

The plasma arc is generated by applying high-frequency electricity between the electrode at the tip of the torch and the object to be cut. The electrode at the tip of the torch is heated by the electricity flow, and the surrounding air molecules are ionized and become plasma.

The plasma arc is maintained by the plasmaized gas and becomes extremely hot (approx. 20,000°C). This high-temperature plasma arc melts the metal, which is then blown away by high-pressure air for cutting.

Air Plasma Cutting Machines are also available in a water injection type equipped with an internal cooling system. Since the area around the plasma arc becomes very hot, cooling water is injected to release the heat, thereby extending the life of the torch.

The water injection type also has the advantage of improving cutting accuracy because the heating caused by the plasma arc is reduced.

Other Information on Air Plasma Cutting Machine

Advantages of Air Plasma Cutting Machine

Air Plasma Cutting Machines have the following four advantages: it can cut plates up to 100 mm thick, can cut materials that cannot be cut by gas cutting such as stainless steel and aluminum alloy, can cut curves with relative ease, has low running costs, is simple to operate, and is safe.

The advantages are as follows:

1. High precision cutting

Since plasma arc is used, the material is melted by heat and no residual stress is generated on the cut surface. Therefore, the cut surface is smooth and clean. Cutting can also be performed using a CNC machine, which enables high-precision cutting processing.

2. Energy saving

The material melted by the heat generated by the plasma arc is discharged at high speed. This reduces power consumption and saves energy.

3. High flexibility

During cutting, the quality of the cut surface can be changed by feeding cleaner gas between the torch and the object to be cut. This allows appropriate cutting conditions to be set when cutting sheet metal of different materials and thicknesses.

4. Low-cost introduction

Compared to other cutting technologies, the cost of equipment is low, making it possible to introduce the system at a low cost. Also, the consumables used are inexpensive, so running costs can be kept low.

List of 12 Air Plasma Cutting Machine Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- China

- India

- Japan

-

-

-

DAIHEN Corporation

Welding Machines/Cutting Machines

Manufacturer Overview

DAIHEN Corporation, established in 1919 and headquartered in Osaka, Japan, is a manufacturer of Power Products, Industrial Robots, and RF/MW Generators & Automatic Matching Units for plasma applications. The company provides an extensive array of products, including Oil-immersed Transformer, Cast Resin Transformer suitable for high buildings, public facilities, and hospitals, Power Distribution Equipment such as closed type power distribution boards and remote monitoring systems, as well as Sensors for Robot Welding and Positioners & Sliders. The company also offers various welding & cutting machines, including TIG Welding Machines, Plasma Cutting Machines, as well as Peripheral Devices for Welding.

-

-

-

-

-

DH Welding Equipments.

Air Plasma Cutting Machine

Manufacturer Overview

DH Enterprises, established in 2012, is a welding machine manufacturer based in Ghaziabad, Uttar Pradesh, India. The company's machine portfolio includes a range of welding machines, including arc and submerged arc, metal inert gas (MIG), and tungsten inert gas (TIG) welding machines. It also manufactures cutting machines, including air and computer numerical control (CNC) and plasma cutting machines. It further offers related accessories and products, such as welding clamps, electrodes, and cables. The company serves both domestic and international markets with notable customers including Adani Power Ltd., Tata Motors Ltd., and the Indian Space Research Organisation (ISRO).

-

-

-

-

-

S. R. Advantech Systems Pvt Ltd

Air Plasma Cutter

Manufacturer Overview

S.R. Advantech Systems Pvt. Ltd. is a welding machine manufacturer, established in 1992 and based in Hyderabad, Telangana, India. The company’s range of welding machines features technologies including diodes, insulated gate bipolar transistors (IGBTs), and metal oxide semiconductor field effect transistors (MOSFETs). Its product offerings include arc and submerged arc, metal inert gas (MIG), and tungsten inert gas (TIG) welding machines. The company serves various industries, predominantly the liquefied petroleum gas (LPG) cylinder manufacturers in South and Western India. Some of its notable customers include Bekem Infra Projects Pvt. Ltd., MG Automotives Pvt. Ltd., and Vijay Electronics.

-

-

-

-

-

ANDELI GROUP CO.,LTD

Air Plasma Cutter

Manufacturer Overview

Andeli Group Co. Ltd., established in 1985, is a Chinese manufacturer based in YueQing, Zhejiang, specializing in welding machines. The company’s product range, marketed under the ANDELI brand, includes arc and submerged arc, metal inert gas (MIG), and tungsten inert gas (TIG) welding machines. Some of its featured products are inverter direct current (DC) manual metal arc (MMA) welding machines, inverter DC auto-submerged arc welding machines, and inverter DC pulse TIG/MMA welding machines. The company has expanded its business operation, producing 10,000 types of electrical devices, including cables, wires, and power transformers, and serving customers in over 50 countries worldwide.

-

-

-

-

-

Arcraft Plasma Equipments (I) Pvt Ltd.,

Air Plasma Cutting Machine

Manufacturer Overview

Arcraft Plasma Equipments, established in 1992 and based in Mumbai, India, is a manufacturer of welding, cutting, and welding automation equipment. The company also produces other products such as metal cutting and welding machines, hard facing and cladding systems, and plasma cutting machines and supplies to different industries such as defense, mining and drilling, civil construction, and power generation. All the products are exported to different countries such as South America, England, Malaysia, Kenya, and Dubai.

-

-

-

-

-

Huaheng Automation Pvt. Ltd.

Air Plasma Cutting Machine

Company Overview

Huaheng Automation Pvt. Ltd., established in 1995 and now a subsidiary of the China-based Huaheng Welding Co. Ltd., is a manufacturer and supplier based in Vadodara, Gujarat, India, providing automatic welding solutions. The company provides a range of welding solutions, including orbital and mechanized welding systems as well as metal inert gas (MIG) and tungsten inert gas (TIG) welding machines, commonly utilized in industries, such as automotive, shipbuilding, and steel. The company also offers pipe prefabrication systems designed for construction, engineering machinery, maritime, and many other sectors. It further produces automated laser and plasma-cutting machines for various industrial applications.

-

-

-

-

-

M/s. Lakshmi Machines, Chennai

Air Plasma Cutting Machines

Company Overview

M/s. Lakshmi Machines, established in 2004 and based in Chennai, Tamil Nadu, India, is a manufacturer and supplier of Welding and Cutting Machines. The company's product range includes Air Plasma Cutting Machines, CNC Profile Cutting Machines, Laser Cutting Machines, Automated Plasma Cutting Systems, and Air Plasma Consumables Thermal Dynamic Hypertherm Kjellberg. These products serve industries like construction, automotive, and aerospace, which require precise welding and cutting equipment. Additionally, the company offers maintenance and repair services for its range of machines.

-

-

-

-

-

Quality Engineering (Baroda) Private Limited

Air Plasma Cutting Machine

Company Overview

Quality Engineering (Baroda) Private Limited, established in 1978 and based in Vadodara, Gujarat, India, is a manufacturer and supplier of Welding and Cutting Machines. The company's product range includes full thyristor Welding and Cutting Machines, Tig Welding Torches, MIG Welding Torches, and Welding Fixtures. These products are designed for various welding and cutting processes. It serves industries such as Larsen and Turbo Limited Baroda, Indian Railways, and Bhabha Atomic Research Center. Additionally, the company provides services like repair and maintenance of equipment and ensures the safety and quality of its offerings.

-

-

-

-

-

Westweld Ltd.

Air Plasma Cutting Machine

Company Overview

Westweld, established in 2006 and based in Clonakilty, Co. Cork, Ireland, is a manufacturer and supplier of Stainless & Mild Steel Tanks. The company's product range includes Stainless Steel Tanks, Mild Steel Tanks, Silos, Ducting, and Structural Steelwork. These products find applications in the storage and processing of various liquids and gases. Westweld primarily serves industries such as Dairy, Brewing, Food Production, and Pharmaceuticals. The company's services include precision fabrication, project management, and bespoke design services.

-

-

-

-

-

Canary Electricals Pvt. Ltd.

Air Plasma Cutting Machine

Company Overview

Canary Electricals Pvt. Ltd. is an Indian manufacturer and supplier producing welding machines, established in 1980 and based in Morbi, Gujarat. The company’s welding machine portfolio includes spot, metal inert gas (MIG)/metal active gas (MAG), and tungsten inert gas (TIG) welding machines. The company also provides other products, such as inverter manual metal arc (MMA) series, step-up transformers, and plasma-cutting machines. It further offers single and two-stage air compressors, flanged- and foot-mount induction motor, and electroplating rectifier equipment. These products are supplied to customers in various regions, including Africa and the Middle East.

-

-

-

-

-

Hypertherm, Inc.

Air plasma

Company Overview

Hypertherm, Inc. established in 1968 and based in Hanover, New Hampshire, is a manufacturer and supplier of industrial cutting products and software. The company's product range includes Plasma cutting systems, Waterjet cutting, Robotics, CNCs, and CAM nesting software. These products are utilized in the construction of steel structures, aerospace components, and transportation equipment. Key industries served by the company are manufacturing, aerospace, construction, and transportation. Additionally, the company offers services in software solutions, customer support, local sales, and service.

-

-

-

-

Air Plasma Cutting Machine Manufacturer Ranking

*Including some distributors, etc.Ranking as of April 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Huaheng Automation Pvt. Ltd. |

13.3%

|

| 2 | S. R. Advantech Systems Pvt Ltd |

13.3%

|

| 3 | ANDELI GROUP CO.,LTD |

13.3%

|

| 4 | Canary Electricals Pvt. Ltd. |

13.3%

|

| 5 | Hypertherm, Inc. |

13.3%

|

| 6 | DH Welding Equipments. |

6.7%

|

| 7 | PUSAN AUTOMATION |

6.7%

|

| 8 | Westweld Ltd. |

6.7%

|

| 9 | Arcraft Plasma Equipments (I) Pvt Ltd., |

6.7%

|

| 10 | DAIHEN Corporation |

6.7%

|

Derivation Method

The ranking is calculated based on the click share within the air plasma cutting machine page as of April 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- DAIHEN Corporation: 3,732

- PUSAN AUTOMATION: 26

- Canary Electricals Pvt. Ltd.: 20

Newly Established Company

- DH Welding Equipments.: 2012 (12 years ago)

- PUSAN AUTOMATION: 2008 (16 years ago)

- M/s. Lakshmi Machines, Chennai: 2004 (20 years ago)

Company with a History

- Quality Engineering (Baroda) Private Limited: 1978 (46 years ago)

- Canary Electricals Pvt. Ltd.: 1980 (44 years ago)

- ANDELI GROUP CO.,LTD: 1985 (39 years ago)

Global Distribution of Air Plasma Cutting Machine Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

India

India

|

8 | 72.7% |

China

China

|

2 | 18.2% |

Japan

Japan

|

1 | 9.1% |

List of Air Plasma Cutting Machine Products

7 products are listed.

Is tail

Air prize cutting machine PowerMAX65

10+ people viewing

HYPERTHERM Air Prasma Cutter PowerMAX Series It is a plasma cutting machine that can be used outdoors. There are options for machine systems that c...

Is tail

Air prize cutting machine PowerMAX30

10+ people viewing

HYPERTHERM Air Prasma Cutter PowerMAX Series It is a plasma cutting machine that can be used outdoors. There are options for machine systems that c...

Is tail

Air prize cutting machine PowerMAX105

10+ people viewing

HYPERTHERM Air Prasma Cutter PowerMAX Series It is a plasma cutting machine that can be used outdoors. There are options for machine systems that c...

Is tail

Air prize cutting machine PowerMAX45

10+ people viewing

HYPERTHERM Air Prasma Cutter PowerMAX Series It is a plasma cutting machine that can be used outdoors. There are options for machine systems that c...

Is tail

Air prize cutting machine PowerMAX125

10+ people viewing

HYPERTHERM Air Prasma Cutter PowerMAX Series It is a plasma cutting machine that can be used outdoors. There are options for machine systems that c...

Is tail

Air prize cutting machine PowerMAX85

10+ people viewing

HYPERTHERM Air Prasma Cutter PowerMAX Series It is a plasma cutting machine that can be used outdoors. There are options for machine systems that c...