22 Rod End Manufacturers in 2024

This section provides an overview for rod ends as well as their applications and principles. Also, please take a look at the list of 22 rod end manufacturers and their company rankings. Here are the top-ranked rod end companies as of April, 2024: 1.Rod End Supply, 2.Neff Gewindetriebe GmbH, 3.IKO International, Inc..

Table of Contents

1985-2014: Worked for Alstom Corporation, ABB Corporation, and Gadelius Corporation, designing Jungstrom air preheaters and mechanical design of diamond soot blowers. (ABB Corporation: https://new.abb.com/jp)

2014-2021: Worked as an engineering and project manager at Alvos Inc.

https://www.linkedin.com/in/yoichi-hiroki-92192394/

What Is a Rod End?

A rod end is a type of spherical plain bearing.

A rod end is a type of spherical plain bearing.

A spherical plain bearing has a spherical outer ring in a bearing housing (or the inner surface of the housing is spherically machined) and a ball-shaped inner ring with a drilled hole in it. In general, spherical plain bearings and rod-end bearings may also be treated as synonyms.

Link balls and link ball joints are also functionally treated as a type of rod end, but are not covered here.

Uses of Rod Ends

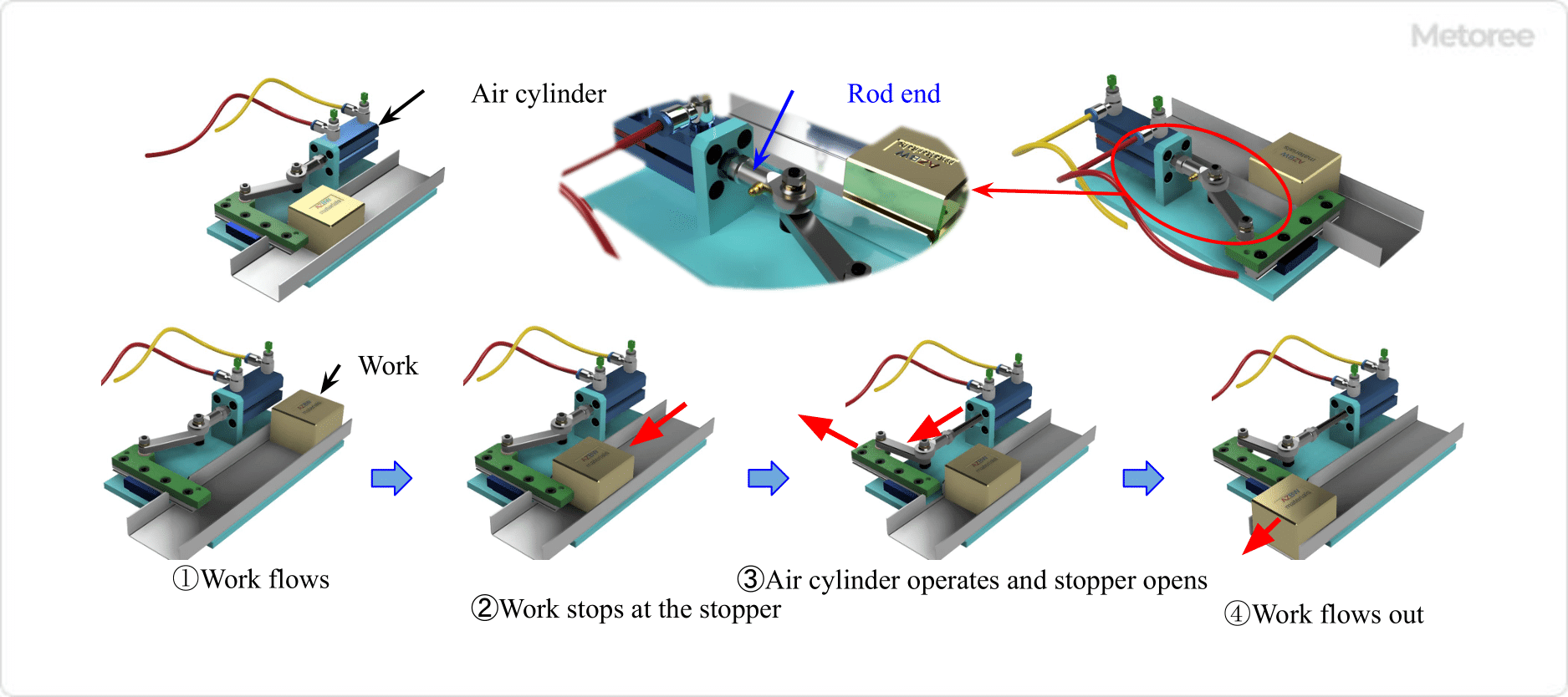

Figure 1. Example of rod end use

Rod Ends are mechanical elements that are used to fasten the housing end of a spherical plain bearing with a male or female thread to the end of a rod (shaft), such as a connecting rod, to fix or connect two parts, and allow the relative displacement of the two parts by means of their spherical plain structure.

It is mainly used to connect parts using links or to transmit linear motion to other parts. They are used in a wide range of fields, including construction machinery, industrial machinery, automobiles, and aircraft.

Rod Ends are used to connect parts by threading male threads, which are threaded at one or both ends of a shaft called a connecting rod, into the female threads of the rod end housing. A pin, shaft, bolt, or other component is inserted into the hole drilled in the center of the rod end's ball-shaped inner ring, and the inner ring and pin or other component are fastened with a nut or other means. The distance between parts and the length of the connecting rod can be adjusted by the screwing depth of the rod end and the connecting rod.

Principle of Rod End

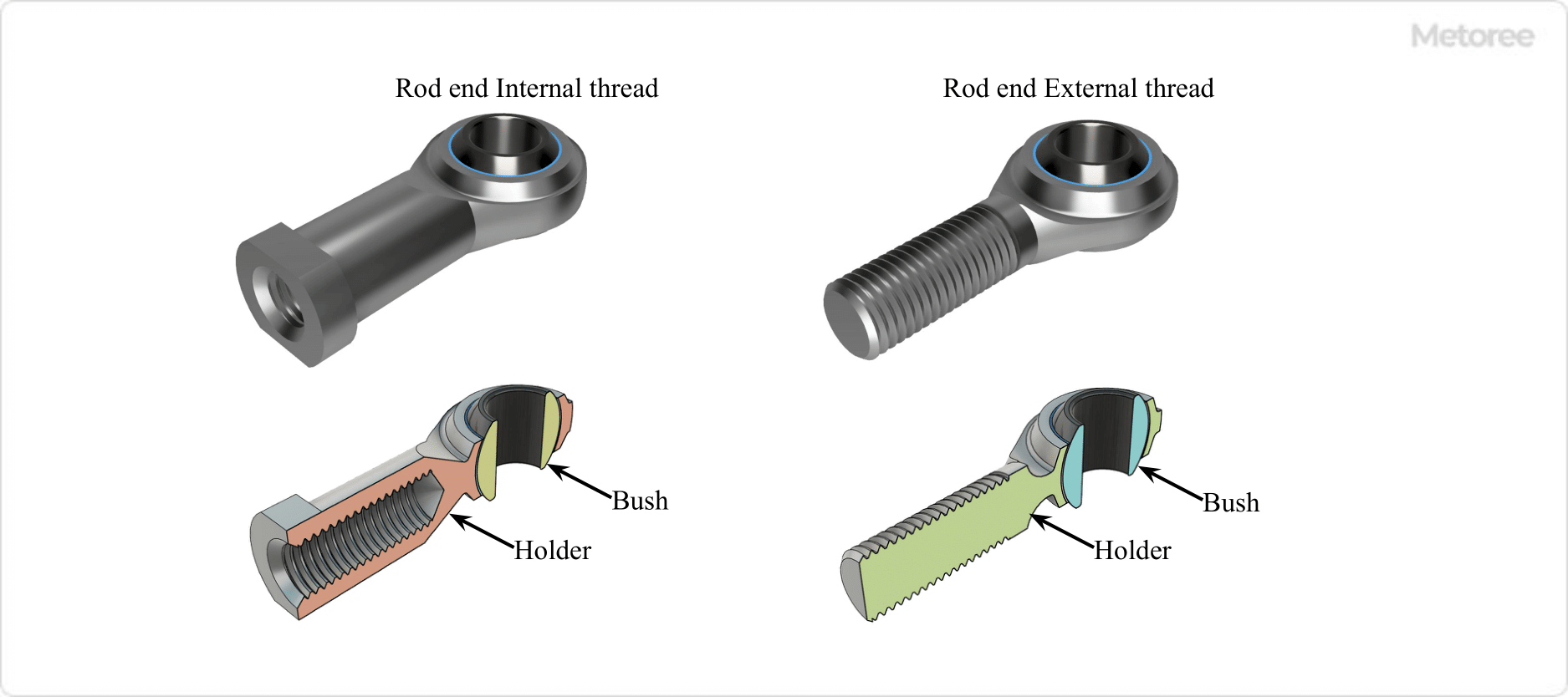

Figure 2. Configuration of rod endchol

Rod Ends consist of a bush that is the inner ring into which bolts and nuts are inserted vertically, and a "holder" that is threaded and connected to other parts such as a connecting rod.

A spherical plain bearing is incorporated. The spherical inner ring ball, which is drilled to insert a bolt or nut vertically, and the outer ring incorporated in the housing make spherical contact to enable smooth and flexible rotational motion.

It acts like a human joint, making it suitable for applications with complex movements. They can also withstand high loads, making them suitable for handling high weights.

Types of Rod Ends

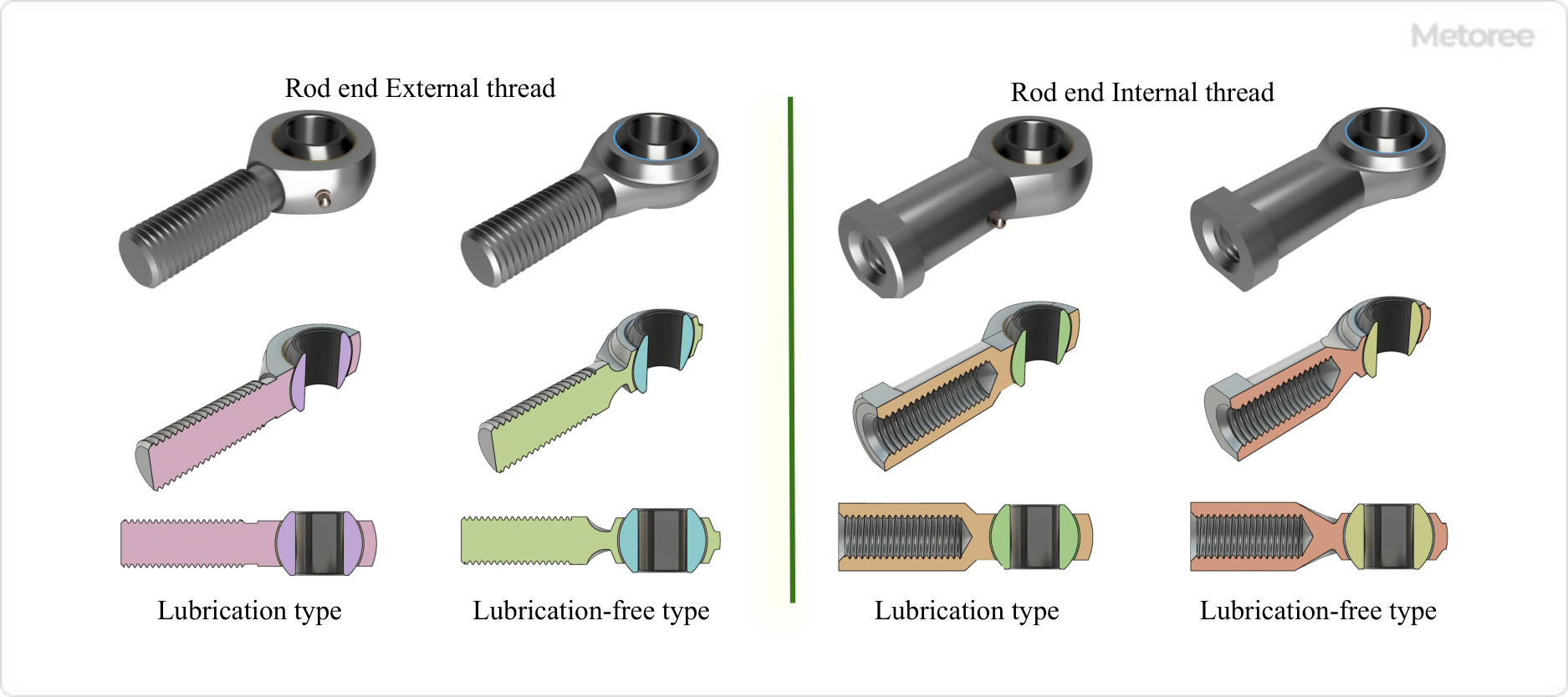

Figure 3. Types of rod ends (Steel)

The holder part of rod end has a male thread and a female thread, and is selected according to the structure of the connecting rod or other parts to be connected.

There are two types of bushings: lubricated and non-lubricated.

1. Lubricated Type

The oil-feeding type has a grease nipple attached to the housing. In the lubricated type, grease is injected through the nipple using a grease gun or the like. In the oilless type, self-lubricating synthetic resin is incorporated in the outer ring of the holder.

2. Oilless Type

Lubrication-free type does not require lubrication, and is used in confined spaces where lubrication is not possible or in maintenance-free applications.

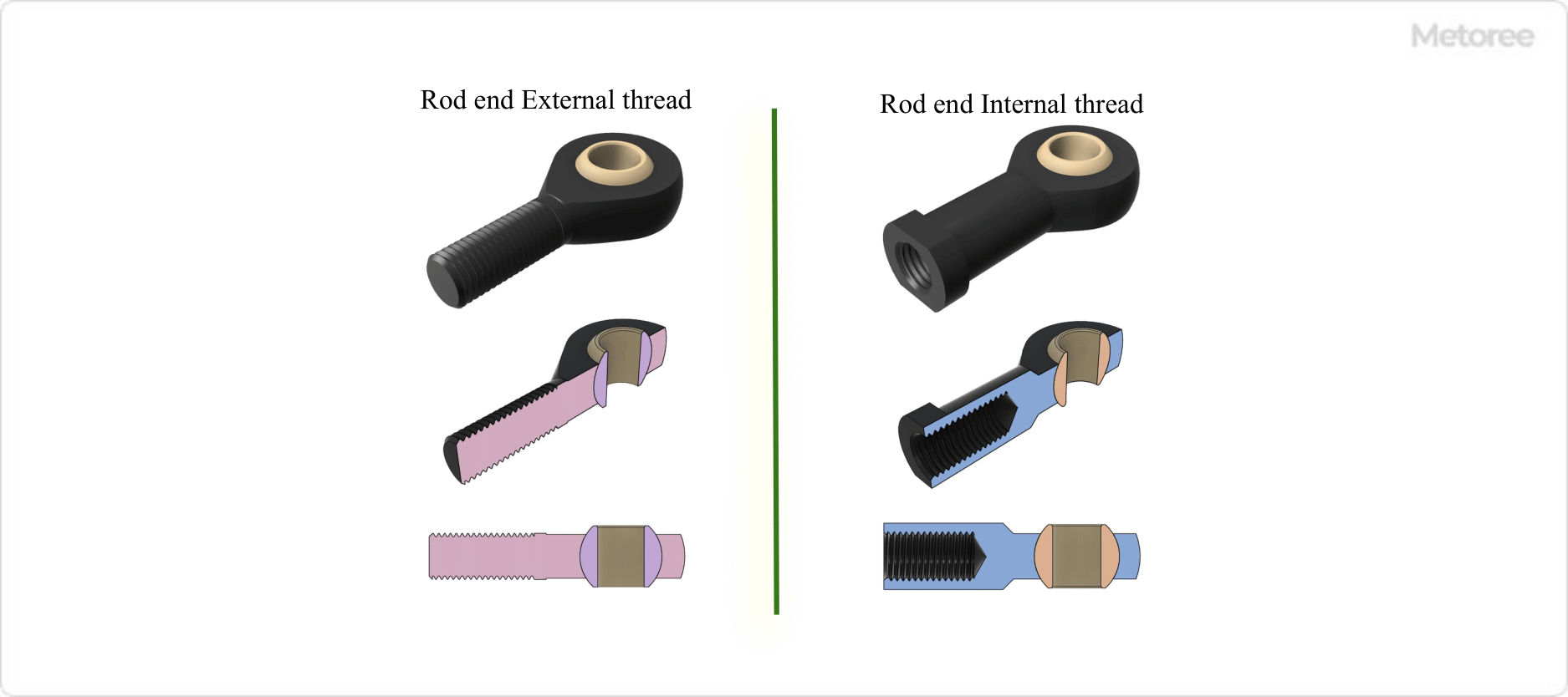

Figure 4. Types of rod ends (Plastic)

Some rod ends are made of resin. Resin contains solid lubricant and can be used without lubrication or oil supply. Compared to metal rod ends, resin rod ends are lightweight and require no oil or grease, making them suitable for use in dusty environments.

It has corrosion resistance, chemical resistance, etc. Resin can absorb vibration, so it can be applied to applications involving vibration.

How to Select Rod End

Rod End should be selected so that the following two points meet the design conditions.

1. Static Load Capacity (Radial Direction)

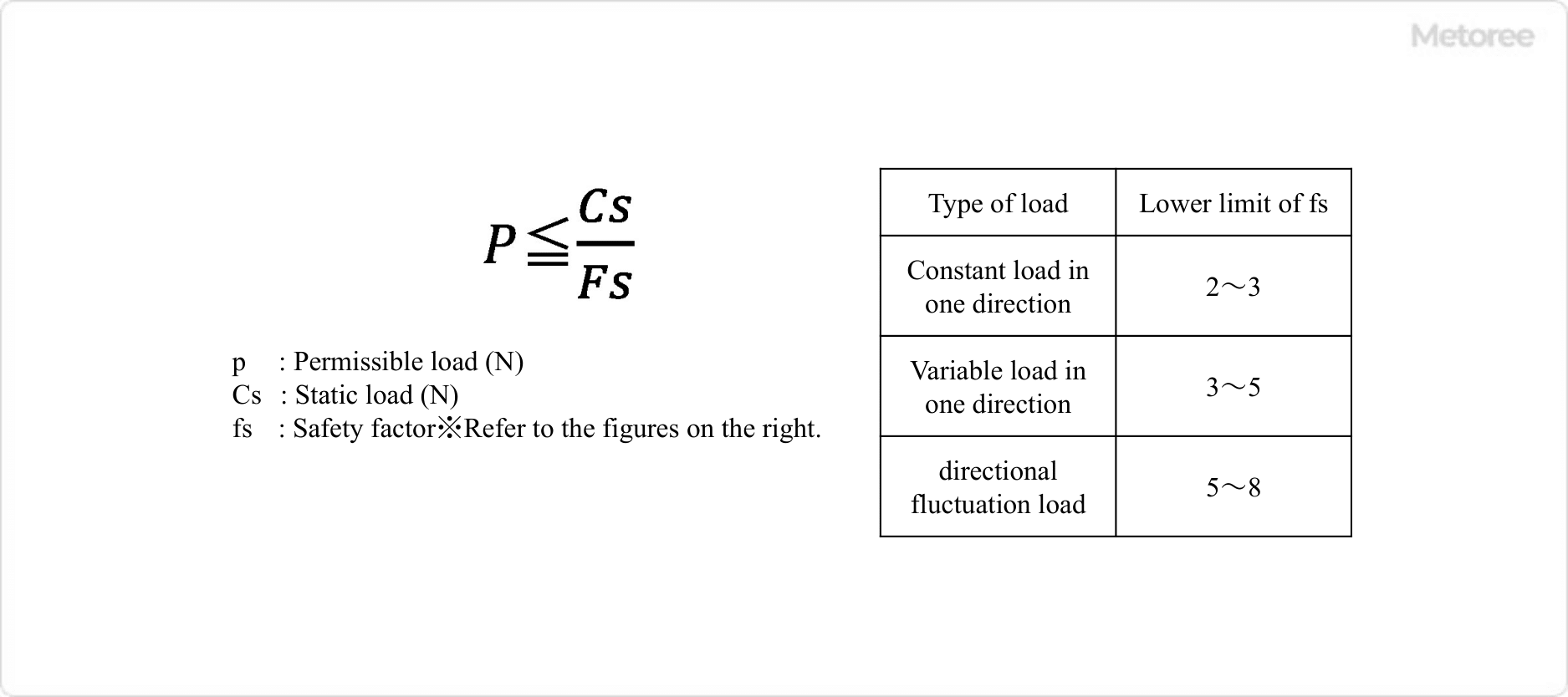

Figure 5. Allowable load calculation formula

Static load capacity is a measure of the mechanical strength of a rod end. Refer to the manufacturer's catalog or instruction manual for details. The allowable load is calculated from the static load capacity using the above formula, and the rod end should be selected so that the load is less than the allowable load.

2. Allowable Inclination Angle

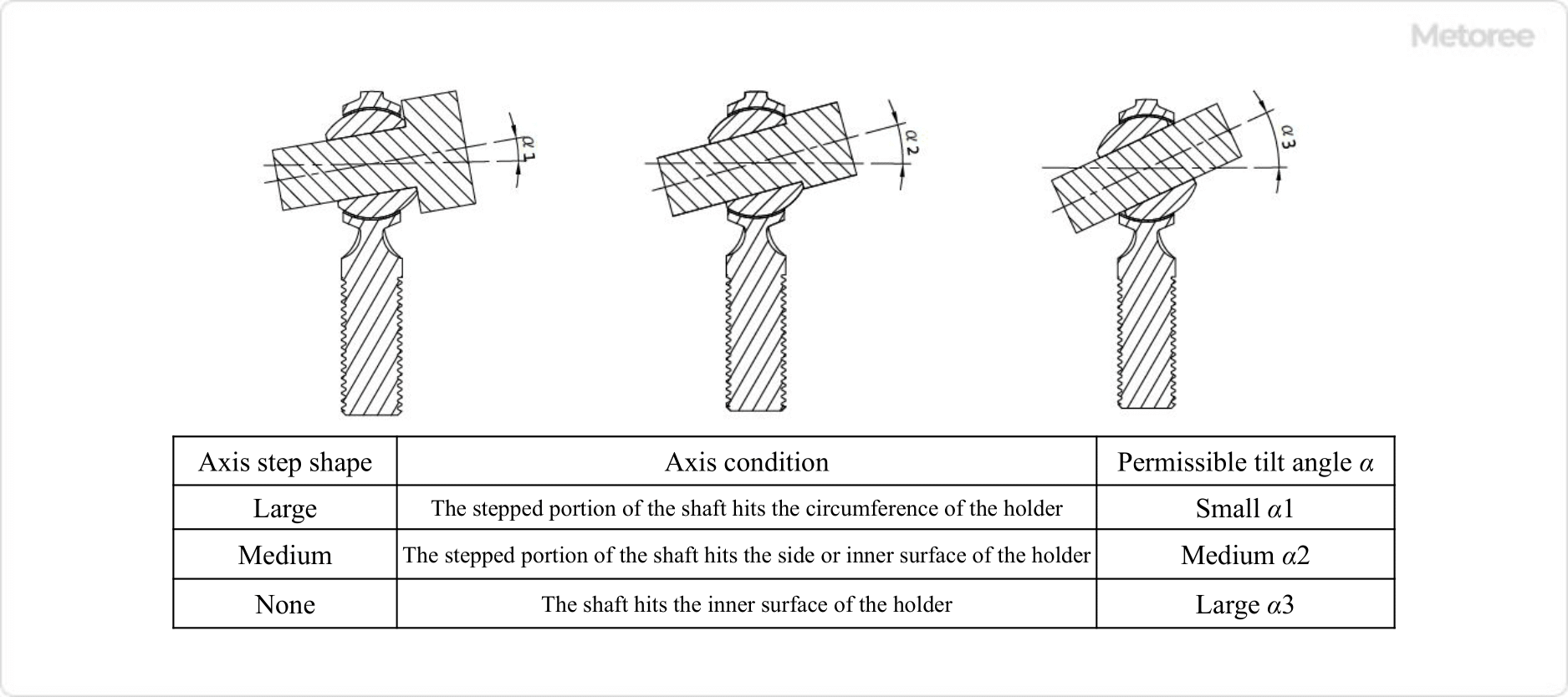

Figure6. Allowable tilt angle

The angle between the centerline of the long axis of the rod end holder and the centerline of the bushing hole is called the tilt angle, which is used within the allowable range when positioning the parts to be connected using the rod end. The allowable inclination angle is also provided by each manufacturer, so please refer to their catalogs or instruction manuals.

List of 22 Rod End Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- China

- Denmark

- Germany

- Japan

- Lithuania

- Sweden

-

-

-

Roller Bearing Company Inc.

Rod Ends

Manufacturer Overview

Roller Bearings Incorporated was founded in 1919 and is headquartered in Oxford, Connecticut. RBC manufactures and markets precision bearings and related components globally, mainly to the aerospace, agricultural, automotive, industrial, and semiconductor manufacturing sectors. The company’s products are primarily divided into two market segments: aerospace and industrial. Both segments include basic components such as airframe control ball bearings, needle track rollers, ball bearing rod ends, and thin-section ball bearings. The Aerospace Segment also includes special machine components while the Industrial Segment also includes heavy-duty needles roller bearings and self-lubricating bearings subsegments.

-

-

-

-

-

Carl Hirschmann

Rod Ends

Manufacturer Overview

Carl Hirschmann, founded in 1957, with Head Quarter in Fluorn-Winzeln, Germany, is a manufacturer of spherical bearings, rotary tables, clamping systems, axial shaft seals, and synthetic fluid and these products have applications in Medical Engineering, the Aerospace industry, and Automotive/Racing Sports. The company produces Aluminium-Titanium lightweight bearings, Ultralight Tie Rods, and rolled-in-spherical bearings which have applications in Mould &Tool manufacturing, and the Turbine industry. They also provide Rotary indexing tables in single-axis/two-axis/multiple-axis models. They offer indexing/rotating spindle, and hollow axes besides they produce synthetic fluid in two forms namely dielectric fluid and grinding fluid that are used in the automobile sector.

-

-

-

-

-

PIB Bearing, Inc.

Rod Ends

Company Overview

PIB Bearing, Inc. is based in Union City, California, USA, and is a manufacturer and distributor of standard as well as custom bearings for industrial applications that was established in 1983 as Pacific International Bearing. The company produces various bearings including miniature bearings, angular contact bearings, and roller clutch bearings. It also offers bushings, rubber wheels, and oil seals for a range of compatible material transport systems. The company’s products are commonly used in the industrial automation sector, as well as in robotics and machine tools.

-

-

-

-

-

QA1 Precision Products, Inc.

Rod Ends

Company Overview

QA1 Precision Products, Inc. is a manufacturer and distributor of suspension components and driveline parts based in Minnesota, USA, since 1993. The company introduced rod ends and spherical bearings for the performance racing industry. The company manufactures various suspension and driveline components, including rod ends, spherical bearings, shocks and suspension components, carbon fiber driveshafts, and racing products. The company serves the motorsports industry with various racing-specific parts, including adjustable shocks, springs, and suspension accessories.

-

-

-

-

-

CCTY Bearing Company

ROD ENDS

Manufacturer Overview

CCTY Bearing Company, founded in 1996, and headquartered in Zhenjiang, China, is a manufacturer of bearings and assemblies. Its comprehensive range includes ball joints, spherical plain bearings, rod ends, mast guide bearings, as well as metallic & self-lubricating bushings, providing smooth movement, stability, and reduced friction in mechanical systems for efficient functioning and performance of equipment across different sectors such as agriculture, automotive, construction, mining, and transportation. Notably, their quality management systems hold ISO 9001 and TS certification.

-

-

-

-

-

HANGZHOU CHINABASE MACHINERY CO., LTD.

Rod Ends

Manufacturer Overview

Hangzhou Chinabase Machinery Co., Ltd., founded in 1992 and based in Hangzhou, China, is a manufacturer specializing in an array of products, including power transmission components. Its key products encompass chains and sprockets for industrial power transmission, gearboxes to enhance torque and reduce speed, couplings for shaft connections, and gears used across industrial applications. Its products find applications in automation, conveyor technology, packaging, food, pharmaceuticals, and more. The company maintains quality and sustainability, holding certifications like ISO 9002, ISO 9001, API, ISO/TS 16949:2002, and ISO 10012 measurement management system.

-

-

-

-

-

Neff Gewindetriebe GmbH

HIGH-PERFORMANCE ROD END

Manufacturer Overview

Neff Ballscrews is a German manufacturer specializing in ballscrews, linear actuators, and motion control products, established in 1952. The company offers a diverse product range, including Acme, Roller, and Spherical ballscrews, as well as linear actuators. These products serve the machine tool, automation, and robotics sectors. Neff Ballscrews also provides engineering services, customization, and repair and maintenance services to meet specific customer requirements. With a global presence, including offices in the United States, China, and Japan, Neff Ballscrews has over 70 years of industry expertise. They are committed to innovation and consistently deliver high-quality products and excellent customer service.

-

-

-

-

-

-

-

THK U.K.

Rod End

Manufacturer Overview

THK Co., Ltd. was incorporated in 1946 and is headquartered in Tokyo, Japan. THK is a manufacturer and supplier of machine components such as linear motion components for customers globally. THK’s products are used in many industries including electronics, aerospace, industrial robots, and precision instruments. THK’s primary product categories are Linear Motion, Feed Screw, Rotation, Custom Assemblies, and Seismic Isolation. Linear Motion products assist in linear motion and transportation. They include linear motion actuators, guides, and rollers. Feed screws include ball screws, screw nuts, and change nuts. Seismic Isolation includes both large systems and small guides.

-

-

-

-

-

MinebeaMitsumi Inc.

Rod end bearings

Manufacturer Overview

MinebeaMitsumi Inc. was incorporated in 1951in Japan and manufactures and supplies machined components, and electronic devices and components globally. It operates through four segments: machined components, electronic devices and components, MITSUMI Business, and the U-Shin business segment. MinebeaMitsumi specializes in bearing products including spherical, roller, rod end, and ball bearings for aerospace. MinebeaMitsumi also produces products including precision mechanical assemblies, fasteners, other special components including clutches and brakes, motors, blowers, sensors and lighting devices. Additionally, MinebeaMitsumi offers its products for use in PCs and peripheral equipment, information and telecommunications equipment, household electrical appliances, automobiles, and aerospace.

-

-

-

-

-

SKF

Rod Ends

Manufacturer Overview

SKF UK is the British division of SKF, originally founded in 1907 and headquartered in Gothenburg, Sweden. SKF designs, develops, and manufacturers bearings, seals, lubrication systems, and services worldwide, with industrial and automotive segments, providing solutions for industries including aerospace, agriculture, transportation, food and beverage, general machinery, material handling, mining, energy, paper, and wind energy. SKF UK offers rolling bearings, mounted bearings, automotive seals, lubrication management, vehicle aftermarket services, waste electric products, and electronic equipment products as well as services including maintenance, remanufacturing, customization, and training.

-

-

-

-

-

Designatronics

Female Rod Ends

Manufacturer Overview

Designatronics is based in New York, New York, USA, and is a manufacturer of mechanical products and components that was established in 1960 following the acquisition and subsequent merger of Quality Bearings & Components, QTC Metric Gears, SDP/SI, and Wybur Tools. The company’s products include belt and chain drives for enabling motion and power, gears for transmitting motion and power, and various shafts for supporting and connecting assembly components. The company’s products are used mainly by clients in the aerospace, automotive, and defense sectors.

-

-

-

-

-

igus GmbH

Spherical bearings

Manufacturer Overview

igus GmbH, established in 1964 and based in Cologne, Germany, is a manufacturer and distributor of technical products made using polymers for movement. Its products include injection molding frames, motor control systems, and plain bearings, and it has over 240,000 products in over 1,000,000 variations. It serves 188,000 companies from over 80 countries worldwide in 50 different industries, including packaging, automotive, and renewable energy. The company is ISO 9001, ISO 14001, and ISO 50001 certified, and in 2023, it recorded €1.115 billion in sales. Since 2021, the company has purchased 380 new injection-molding machines and has replaced 275 old ones.

-

-

-

-

-

THK America, Inc.

Rod Ends

Manufacturer Overview

THK America Inc., located in Schaumburg, Illinois, is a manufacturer of linear motion guides used in the production of liquid crystals, semiconductors, medical equipment, and amusement devices. The company also offers actuators, slide rails, flat rollers, roller guides, and linear ball slides. Other products include seismic isolation devices, ball screws, rod ends, and XY tables. In addition to its headquarters, the company has regional offices in Atlanta, Detroit, Mississauga, New York, San Francisco, and Ontario. In 2022, the company was ranked first in the annual survey of Quality Leadership by Quality Magazine for demonstrating superior quality and performance.

-

-

-

-

-

NIPPON THOMPSON CO., LTD.

PILLOBALLS

Company Overview

Nippon Thompson Co., Ltd. - IKO is based in Japan and was established in 1950 as a manufacturer of bearings. The company designs Linear Motion Rolling guides and Mechatronics series and they were the first to produce Needle Roller Bearings. These products have vast applications in various industries as they are used in Electronics-related Devices and Equipment like semiconductors and for precision devices that are used in laboratory measuring instruments and medical equipment. Textile, printing, construction, transportation, and robotics are also on the list of industries that benefit from IKO products.

-

-

-

-

-

CRAFT bearings JSC

Rod Ends

Company Overview

Craft Bearings JSC, founded in 1992 and located in Kaunas, Lithuania, is a manufacturer and supplier of bearings. The company’s product line includes bearings, rod ends, adapter sleeves, and chains. Its products are applicable in the automotive, industrial, and agricultural industries. The company runs a quality control laboratory, conducting tests for bearing life, noise and vibration, grease leakage, and metal structure in its products with precise measuring equipment, according to ISO standards.

-

-

-

-

-

-

-

-

-

Alinabal, Inc.

Rod Ends

-

-

-

-

-

IKO International, Inc.

Rod Ends

Company Overview

IKO International, Inc. founded in 1950 and headquartered in Parsippany, New Jersey is a manufacture of needle bearings, linear motion rolling guides, precision positioning tables & machine components. The company offers specialized solutions for diverse manufacturing environments, including clean rooms, vacuum conditions, high-temperature settings, and locations with dust or spatter protection. IKO also exclusively provides C-Lube, a maintenance-free lubrication system with a lifespan of up to 5 years or 12,500 miles for M series linear ways and maintenance-free cam followers.

-

-

-

-

-

Rod End Supply

Rod Ends

-

-

-

-

-

PTI EUROPA A/S

Rod Ends

Distributor Overview

PTI EUROPA A/S is a supplier of bearings and transmission parts, founded in 1991 and located in Tønder, Denmark. The company’s products include plummer blocks, belts and belt pulleys, ball and roller bearings, rod ends, and roller chains. It is an ISO 9001:2015 certified company which provides powder coating, technical documentation, and 2D/3D drawing services. It also provides adaptation and processing services, adjusting product features such as increasing the diameter of products like bearing housings.

-

-

Rod End Manufacturer Ranking

*Including some distributors, etc.Ranking as of April 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Rod End Supply |

11.7%

|

| 2 | Neff Gewindetriebe GmbH |

8.5%

|

| 3 | IKO International, Inc. |

8.5%

|

| 4 | PTI EUROPA A/S |

7.4%

|

| 5 | THK U.K. |

7.4%

|

| 6 | MinebeaMitsumi Inc. |

6.4%

|

| 7 | CRAFT bearings JSC |

5.3%

|

| 8 | Roller Bearing Company Inc. |

5.3%

|

| 9 | HANGZHOU CHINABASE MACHINERY CO., LTD. |

4.3%

|

| 10 | Designatronics |

3.2%

|

Derivation Method

The ranking is calculated based on the click share within the rod end page as of April 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- MinebeaMitsumi Inc.: 85,954

- THK U.K.: 13,502

- NIPPON THOMPSON CO., LTD.: 2,673

Newly Established Company

- HANGZHOU CHINABASE MACHINERY CO., LTD.: 1992 (32 years ago)

- PTI EUROPA A/S: 1991 (33 years ago)

- Rod End Supply: 1989 (35 years ago)

Company with a History

- SKF: 1907 (117 years ago)

- Roller Bearing Company Inc.: 1919 (105 years ago)

- MinebeaMitsumi Inc.: 1951 (73 years ago)

Rod End Manufacturers in United States

*Including some distributors, etc.

Global Distribution of Rod End Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

6 | 37.5% |

United States of America

United States of America

|

4 | 25.0% |

China

China

|

2 | 12.5% |

Germany

Germany

|

1 | 6.3% |

Sweden

Sweden

|

1 | 6.3% |

Lithuania

Lithuania

|

1 | 6.3% |

Denmark

Denmark

|

1 | 6.3% |