148 Flexible Hose Manufacturers in 2024

This section provides an overview for flexible hoses as well as their applications and principles. Also, please take a look at the list of 148 flexible hose manufacturers and their company rankings. Here are the top-ranked flexible hose companies as of April, 2024: 1.Clippard, 2.Graco Inc. , 3.Anver Corp..

Table of Contents

What Is a Flexible Hose?

A flexible hose (flexible tube) is a hose that can be bent freely.

The materials used include rubber, plastic, and fluoroplastic, but in most cases, the term "flexible hose" refers to hoses made of metal. Most flexible hoses made of metal have a wavy structure called bellows.

Bellows are piping made by bending metal into a jagged shape, which allows even hard-to-bend metal pipes to be bent flexibly.

Uses of Flexible Hoses

Flexible hoses are used for piping in factories and for connection to vibrating devices such as mobile equipment and pumps. They are used not only for industrial applications but also for household gas and water piping.

Other applications include the middle section of automobile exhaust pipes, vacuum piping for semiconductor manufacturing equipment, and sprinkler connections for firefighting piping.

Flexible hoses are used not only for water but also for other liquids and gases. Because it can be bent, the hose can be freely installed. The material of the hose is selected according to the liquid or gas to be flowed through the hose, and flexible hoses made of fluorocarbon resin may be used for highly corrosive liquids or gases.

Principle of Flexible Hoses

Flexible hoses are used in a wide range of situations by taking advantage of their flexibility, as described above. The following characteristics are demonstrated in each usage scenario.

1. Simplification of Piping Work

Used in locations where straight piping cannot be connected or where intricate piping connections are required. Even a slight misalignment in rigid piping makes it difficult to connect, but flexible hoses make it easy to do so.

2. Displacement Absorption

When a hose expands, contracts, or becomes eccentric due to aging deterioration of equipment or ground subsidence, the connection part or the hose itself is loaded if it is a normal hose. (Elongation refers to a change in the length of a straight hose relative to the direction of extension, while eccentricity refers to a change in the direction perpendicular to the direction of hose extension.) The use of flexible hoses can absorb such displacement.

3. Vibration Absorption

When a hose is connected to equipment that constantly vibrates, such as a pump, the vibration places a load on the hose itself and its connections. Flexible hoses absorb the vibration, thereby reducing the load on the equipment and, as a result, contributing to extending the service life of the equipment. It also absorbs shaking during earthquakes to reduce damage to equipment.

4. Absorption of Thermal Expansion of Piping

Rigid metal piping does not appear to expand or contract at first glance, but it actually expands and contracts slightly due to rapid temperature changes. Because it is a rigid structure, the slightest change in size can lead to loading. Since flexible hoses are themselves expandable and contractible components, they can accommodate such expansion and contraction.

Structure of Flexible Hoses

Normally, metal is too rigid to be bent and stretched, but flexible hoses can be bent freely and used as hoses.

Typical flexible hose structures and features are described below.

1. One-Pitch Type

As mentioned at the beginning of this section, it has a structure called bellows. It is a thinly stretched piping formed into a structure with continuous peaks and valleys like an accordion. It is easy to understand if you imagine a folded straw. Each mountain is independent and separated by a valley.

2. Annular Type

Similar to the one-pitch type, there are mountains and valleys, and each mountain is independent. However, in the one-pitch type, the mountains are U-shaped, whereas in the annular type, the mountains are omega-shaped. The feature of this type is that each mountain is independent, which reduces twisting at the neck.

3. Spiral Type

The U-shaped mountains are formed in a continuous spiral shape. The spiral structure is characterized by its resistance to liquid accumulation.

4. Blade Type

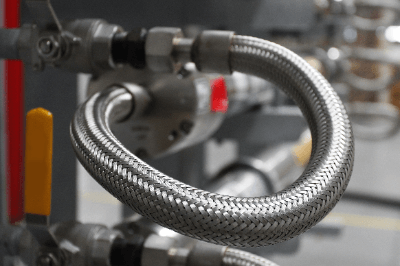

Instead of the structure of peaks and valleys, as described so far, this type has a tubular structure made of thin metal wires woven together like fibers of clothes.

Not only the above structures but also combinations of them are made. In many cases, a one-pitch or spiral type hose is reinforced on the outside with a braid type to create a double structure, making the hose both flexible and durable.

Other Information on Flexible Hose

1. Features of Flexible Hoses

Flexible hoses are characterized by their strength and pressure resistance, improved heat resistance, flexibility, ability to accommodate large displacements and effectiveness in preventing the transmission of equipment vibration.

- High Performance

By covering the outer surface of the flexible tube with a braided metal layer, strength, and pressure resistance are increased without compromising flexibility. Applicable fluids include gases such as air, various gases, and steam; liquids such as water, oil, solvents, chemicals, blood, and seasonings; and various powders. They can also be used in a wide range of temperatures, from low to high. Some can be used at several hundred degrees. - Capable of Handling Large Displacements

Flexible hose blades can handle large displacements. These include hydraulic and pneumatic equipment with moving parts, robots, and automobile wheel brakes. They can also be used in seismic isolation equipment and underground piping to reduce damage caused by ground movement during earthquakes. - Vibration Countermeasures

Flexible hoses are used in connection pipes for pumps, compressors, exhaust pipes, etc. Vibration transmission from equipment is suppressed.

2. Blade Type

When the blades are stainless steel, three main types are used.

- Wire Blades

Wire blades are made of stainless steel wire, with several wires bundled in parallel and braided into the outer surface of the tube. It has excellent flexibility and can absorb displacements that are frequently repeated. Also called round wire braid or wire braid. - Strip Braid

Strip braid is made of stainless steel plates cut into strips and manually braided into the outer surface of the tube in the shape of a bamboo basket. Compared to wire braid, it has superior strength against internal pressure, but less flexibility, making it suitable for absorbing displacements with low repetition frequency. Also called plain wire braid or ribbon braid. - Twill Weave Braid

The Twill weave braid is made by braiding the wire into flat plates, which are then woven into the outer surface of the tube. It has high durability and flexibility. It can be used for long lengths of piping but is the most expensive type of braid.

List of 148 Flexible Hose Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- Belgium

- Canada

- China

- France

- Germany

- India

- Italy

- Japan

- Netherlands

- Spain

- Turkey

- United Kingdom

-

-

-

Ultra Clean Holdings, Inc.

Hoses

Manufacturer Overview

Ultra Clean Holdings Inc., founded in 1991 with headquarters in the San Francisco Bay Area, USA, is a manufacturer of chemical and gas delivery components and systems. The company's product line includes valves, fittings, weldments, and heaters. Its systems include modular plastic chemical delivery system modules and subsystems, as well as complete turnkey PFA-grade gas delivery systems used in the manufacture of semiconductors. The company serves many industries, including semiconductor production, semiconductor equipment manufacturing, energy, pharma, and display manufacturing.

-

-

-

-

-

Clippard

Single Vinyl Hose

Manufacturer Overview

Clippard Instrument Laboratory, Inc. was founded in 1941 in Arkansas and is now located in Cincinnati, Ohio. The company is a manufacturer of miniature pneumatic valves, specializing in ultra low leak, precision pressure control, and high-resolution flow control. Categories of Clipard Products include electronic valves, proportional valves, isolation valves, electronic controls, custom solutions, ppressure regulators, control valves, directional control valves, air pilot valves, air preparation equipment, and fittings hose, and tubings.

-

-

-

-

-

Graco Inc.

Water-Wash Hose

Manufacturer Overview

Graco Inc. Was incorporated in 1926 and is headquartered in Minneapolis, Minnesota. The company is a designer, marketer, and manufacturer of systems and equipment for the movement, control, dispensing, and spraying of fluid and powder materials to global customers. The company operates in three segments: industrial, process, and contractor. The industrial segment designs proportioning systems for pumping sealants, adhesives, and other coating materials. The process segment designs pumps used in water, wastewater, and petroleum industries. The contractor segment offers paint and viscous coating sprayers.

-

-

-

-

-

MicroStrain, a LORD Company

High Pressure Hose

Manufacturer Overview

MicroStrain is based in Williston, Vermont, and is an American manufacturer of inertial and wireless sensors originally established in 1987 before being acquired by HBK in 2019. The company produces various industrial and tactical-grade sensors, wireless sensor network devices, and data analysis software. Its products include battery powered wireless 3-axis accelerometers with a rugged and weather-proofed shell, cloud-based platforms for sensor data management or analysis, and software for wireless sensor network control purposes. The company's products are mainly used by clients in the aerospace, automation, and construction industries.

-

-

-

-

-

Coilhose Pneumatics

Twin Bond Nylon Coil

Manufacturer Overview

Coilhose Pneumatics, headquartered in New Jersey, USA, is a manufacturer of pneumatic accessories and solutions since 1969. The company manufactures a comprehensive range of pneumatic products and components including air hoses, tubing, fittings, blow guns, lubricants, regulators, filters, and more. Its products cater to various industrial applications, providing essential components that ensure the smooth functioning of pneumatic systems. Additionally, the company provides solutions to meet the evolving needs of its customers.

-

-

-

-

-

Anver Corp.

Reinforced Plastic Vacuum Hose

Manufacturer Overview

ANVER Vacuum Material Handling Specialists, established in 1975 and located in Elk Grove Village, Illinois, USA, is a manufacturer and supplier of vacuum tube lifting systems and vacuum lifting equipment. The company's product range includes vacuum tube lifters, lifting pads, grippers, generators, and system components, catering to diverse industries such as manufacturing, aerospace, automotive, food and beverage, and material handling. The company’s services entail, testing and certification, supply chain management, and technical support. The company also holds ISO 9001:2015 certification, an indication that it exceeds expectations in quality and service.

-

-

-

-

-

Flexaust, Inc.

Gray PVC hose

Manufacturer Overview

Flexaust, Inc, established in 1938, is a manufacturer and supplier of flexible hose and ducting solutions for agricultural, woodworking, automotive, and floor care applications. The product line has industrial cleaning tools, commercial cleaning tools, wands, and extensions. Industrial and commercial cleaning tools include floor brushes, pipe cleaning tools, squeegee blades, and snap rings. The company also supplies hoses and accessories, including floor care hoses, floor care cuffs, connectors, adapters, and industrial hoses such as bridge clamps, flanges, reducers, and cuffs used in applications involving air, dust, fume, and lightweight materials such as dust collection and static control in woodworking facilities.

-

-

-

-

-

Norgren Ltd

Metal braided rubber hose

Manufacturer Overview

IMI Precision Engineering, a company established in 1921, headquartered in Birmingham, United Kingdom, is a manufacturer and supplier of precision engineering products and solutions in the industry. The company offers a wide range of innovative products, including pneumatic and fluid control technologies, motion and fluid control systems, and process valves. Their solutions find applications across various industries, including automotive, aerospace, healthcare, and industrial manufacturing. The company also offers services such as technical support, custom engineering solutions and after-sales support to meet the customer’s needs.

-

-

-

-

-

MDC Precision

Braided Flexible Stainless Steel Hose

Manufacturer Overview

MDC Precision is a manufacturer of precision components since 1975 and is headquartered in Hayward, California with additional Pflugerville, TX, Sarasota Florida, Lyon, France, Milton Keynes, UK, and Vietnam. Its product portfolio includes viewports & glass components, electrical feedthroughs, vacuum flanges, roughing components, and vacuum valves such as hybrid adapters, elbows, watercooled clamps, flexible couplings, and crosses. They have fulfilled the ISO 9001:2015 certification and their products are used in life science & medical, semiconductor manufacturing, aerospace, food processing, and research sectors.

-

-

-

-

-

Fox Valley Paint

Swan WeatherFLEX Hose

Manufacturer Overview

Fox Valley Paint, headquartered in Connecticut, United States, is a manufacturer of a range of paints and pertinent machines plus accessories. The company fabricates traffic striping paints, athletic striping paints, and utility marking paints. It also makes easy marker pistols, athletic field striping paint machines, and stencil kits. Its traffic striping paints are weather and abrasion-resistant, ensuring a smooth application with no runs or dips. It leverages environmentally friendly manufacturing techniques to run the production.

-

-

-

-

Manufacturer Overview

Flexon Industries, established in 1956 and based in Newark, New Jersey, USA, is a manufacturer of lawn and garden hoses. The company’s products include soaker hoses, 3-tube sprinklers, hot water rubbers, soaker kits, and Streamtech heavy-duty water hoses. It offers a warranty against manufacturing defects and is a member of the U.S. Wire & Cable Corporation family of companies, which includes Winzeler Couplings & Metals, U.S. Wire & Cable, and Voltec Power & Lighting.

-

-

-

-

Manufacturer Overview

Hamilton Precision Metals | AMETEK Specialty Metal Products, established in 1939 and based in Collegeville, Pennsylvania, USA, is a manufacturer and supplier of advanced metal products. The company's product range includes precision metal tubes, precision metal strip and ultra-thin foil, water atomized metal powders, roll-bonded clad plate, and shaped wire. Thesel products are used in industries such as medical devices, aerospace, defense, and energy. Additionally, the company offers thermal management products and engineered shaped components as part of its extensive services.

-

-

-

-

-

Jaeco Fluid Systems, Inc.

Stainless Steel Flexible Hose

Manufacturer Overview

Jaeco Fluid Systems Inc., founded in 1948 with headquarters in the USA, is a manufacturer of metering pumps and check valves. The company's product line includes diaphragm metering pumps, plunger metering pumps, hi-flo pumps, pump maintenance parts, and a range of stainless steel check valves. These products are built-to-order and are used in various applications such as irrigation, chemical processing, and car wash. The company serves various markets including automotive, agriculture, food processing, petrochemical processing, among others.

-

-

-

-

-

Freelin-Wade Co.

Flexible Hoses

Manufacturer Overview

Freelin-Wade Co., founded in McMinnville, OR, in 1980 is a manufacturer of custom plastic tubing. The company's product portfolio includes nylon tubing, polyethylene tubing, polyurethane tubing and PVC tubing and their products are phthalate-free, non-reinforced PVC tubing that prevents harmful toxins from entering material flowing through the tubes. They serve markets such as Packaging Equipment and Robotics, Food and Beverage, Medical Tubing, Agriculture and Water Purification. They also offer custom packaging, warehousing, and distribution services.

-

-

-

-

-

Metal Goods Manufacturing, Inc.

FLEXIBLE CONNECTING HOSES

Manufacturer Overview

Metal Goods Manufacturing Inc., founded in 1939 with headquarters in the USA, is a manufacturer of check valves, fittings, and gauges. The company's product line includes a range of excess flow check valves, back pressure check valves, thermometer well fittings, stainless steel pressure relief valves, and flexible connecting hoses. These products are used in lab equipment and instrumentation as well as in stationary tanks, tank cars, tank ships, and barges containing liquids under pressure. The company primarily serves industries such as petrochemical processing, chemical processing, marine transportation, and food processing.

-

-

-

-

-

NORRES North America Inc.

FLEXIBLE HOSES

Manufacturer Overview

NORRES North America Inc., established in 1889 and based in South Bend, Indiana, USA, is a manufacturer and supplier of wire-reinforced industrial flexible technical hose and hose systems. The company's product range includes industrial hoses, cable protection systems, aeration systems, suction and transport hoses, and high-temperature hoses. These products are used for transporting bulk solids, protecting cables, and aeration. It serves the food, pharmaceuticals, agriculture, and plastics manufacturing industries. The company also offers services like hose system solutions development, helping customers enhance productivity, reduce costs, and simplify processes.

-

-

-

-

-

Nor-Cal Products

Flexible Hose

Manufacturer Overview

Nor-Cal Products is a manufacturer and supplier of vacuum and pressure components based in the USA. Founded in 1962, the company has a long history of providing solutions for its clients' vacuum and pressure system needs. The company produces a wide range of components, including flanges, fittings, valves, and chambers, which are essential for creating and maintaining vacuum systems. One of its product lines is its vacuum chambers. These chambers are constructed with precision, ensuring optimal performance in demanding applications. It comes in various sizes and configurations to accommodate different requirements. The company holds the ISO9001:2015 certification for quality management systems.

-

-

-

-

-

FMH/Flexible Metal Hose

Flexible Metal Hoses

Manufacturer Overview

FMH Aerospace Corp. (“FMH”), also known as AMETEK. Inc., is a designer and manufacturer of complex, highly-engineered components and assemblies established in and headquartered in Irvine, California The company produces various complex, tight tolerance, and flight-critical products, including metal bellows, bellow joints, tubes, ducts, and metal hoses. These products are used to facilitate the transfer of fluids and gases at extreme temperatures and pressures and in demanding environments for various industries including the commercial aerospace, defense, space, and industrial markets.

-

-

-

-

-

Flexible Technologies

Flexible Hose

Manufacturer Overview

Flexible Technologies, established in 1947 and headquartered in Abbeville, South Carolina, is a manufacturer specializing in flexible hose and ducting solutions. The company's product range includes spiral wound hoses, self-retracting hoses, electrical hoses, medical hoses and hose accessories, and injection-molded components. The company caters to an array of industries, including military and aerospace, automotive, agriculture, industrial MRO and manufacturing, and home appliances. Its products are marketed under brands such as Hi-Tech Duravent, Hi-Tech Medical, and Flexschlauch.

-

-

-

-

-

Thermal Flex, A Div. of Tacna International

Silicone Hose

Manufacturer Overview

Thermal Flex was founded in 1990 and is based in San Diego, California, U.S.A., and is a manufacturer of silicone hoses for various industrial applications. The company has achieved approval of NAFTA and provides charge air coolers, marine hump hoses, straight hoses, vacuum tubing, and, couplers that have a wide range of applications in the automotive, heavy truck, marine, aviation, and sanitary industries. The company was acquired by TACNA in the year 2000 and offers services including custom coloring, in-house engineering, machining, compounding, and, welding.

-

-

-

-

-

Hose Master LLC

Flexible Metal

Manufacturer Overview

Hose Master LLC, founded in 1982 and based in Cleveland, OH, is a manufacturer of flexible metal hose and metal expansion joints. The company's products are used in steel mills, chemical plants, oil refineries, power plants, and paper mills. The firm was the first ISO-registered hose company in the United States. The company is specialised in producing corrugated metal hose, metal expansion joints, strip-wound metal hose, petroleum flexible connectors, and food service flexible connectors. The business has received ISO 9001:2008 certification and, with “U," "PP," and "R" stamps, complies with ASME Section VIII.

-

-

-

-

-

Southeastern Hose, Inc.

Corrugated Hose

Manufacturer Overview

Southeastern Hose, Inc. founded in 1963 and headquartered in Bremen, Georgia, is a fabricator, manufacturer and supplier of hose and fluid assemblies. Their product range includes industrial hoses, expansion joints, HVAC products, and accessories. These products serve various industries such as oil and gas, food, transportation, and aerospace. Southeastern Hose's offerings are utilized for fluid conveyance, suction and discharge, material handling, and chemical transfer applications. Their solutions enable efficient and safe fluid management in industrial settings.

-

-

-

-

-

NewAge Industries, Inc.

Tubing & Hose

Manufacturer Overview

NewAge Industries began in 1954 as a braid-reinforced, flexible PVC hose company. NewAge Industries is now based in Southampton, Pennsylvania. NewAge Industries’s products are used in fuel and oil, chemical, food and beverage, pharmaceutical, biotechnology, waste handling, water treatment, marine, MRO, packaging mining, energy and nuclear, robotics, computer chip, recreational, and OEM industries. Products include tubing and hose from silicone, polyurethane, PVC, fluoropolymer, nylon, and Viton; barbed, push-to-connect, compression, and cam operated couplings; ear type, nylon double bond, stainless steel worm gear, and plastic pinch clamps, and accessories such as cutters.

-

-

-

-

-

Swagelok

Hoses and Flexible Tubing

Manufacturer Overview

Swagelok Company was founded in 1947 in Cleveland, Ohio as a tube fitting manufacturer. The company serves numerous industries including the chemical, clean energy, food & beverage, industrial machinery, life sciences, and wastewater treatment industries. The copmany's product categories include hoses and flexible tubing, sample cylinders, welding systems, tubing and accessories, and measurement devices. The company's also offers engineering services including field engineering, onsite services, design and assembly services, training, and construction services.

-

-

-

-

-

Flex-Hose Co., Inc.

UltraFuelFlex

Manufacturer Overview

Flex-Hose Co., Inc., situated on Buckley Road in Liverpool, New York, was formed in 1968 and is a manufacturer of metal hose assemblies. The company sells flexible metal hoses, metal expansion joints, rubber or metal expansion loops, in-line air separators, and seismic connectors. It also manufactures pipe guides, expansion compensators, pump connectors, single or double spheres, and control units for use in labs, sanitary systems, water systems, fire protection systems, and gas filters. Its products, which are IBD, ASCE, UL compliant, and NSF, are approved by IAPMO.

-

-

-

-

-

Unisource Manufacturing Inc.

Flexible Metal Hose

Manufacturer Overview

Unisource Manufacturing Inc., founded in Portland, OR, in 1980 is a manufacturer of hose products, expansion joints and hydraulic hose and fittings. The company's product portfolio includes flex connectors for HVAC applications, Sanitary hoses and fittings, Air and Multipurpose Hoses, and industrial hoses used in tank truck service, chemical handling, oil refining and food processing. Their products are used in industries such as Food and Beverage, Pharmaceutical and Biotechnology, Chemical and Petrochemical, Environmental Testing and healthcare.

-

-

-

-

-

Morris Coupling Co.

Flexible Hose

Manufacturer Overview

Morris Coupling is a family-owned company that was founded in 1941 and is headquartered in Erie, Pennsylvania. Morris is a manufacturer of compression coupling and components for pneumatic conveying and industrial vacuum systems. Morris Coupling has additional manufacturing facilities in Tennessee and Georgia, as well as distribution centers in Mexico, Europe, and Asia for international customers. Morris Coupling 7 product lines include couplings, flex hose, bends, and installation components. Most products are available in multiple configurations.

-

-

-

-

-

Industrial Vacuum Equipment Corp.

DUCT HOSE & BRIDGE HOSE

Company Overview

Industrial Vacuum Equipment Corporation is headquartered in Ixonia, Wisconsin. Industrial Vacuum is a distributor, service, and repair provider for industrial vacuum systems used in a variety of industrial settings including painting, asbestos abatement, abrasive blast recovery, hazardous waste removal, and shipyards. Industrial Vacuum’s product categories range from vacuum systems to dust collectors and blowers. Additionally, Industrial Vacuum offers individual parts and accessories. Industrial Vacuum’s offers rental service for industrial vacuums and dust collectors and also offers used equipment service.

-

-

-

-

-

PowerTech Mobile Generators

EXHAUST FLEX PIPE

Company Overview

PowerTech Mobile Generators, founded in 1989 and headquartered in Leesburg, Florida, is a manufacturer of mobile diesel and gas generators ranging from 12kW to 40 kW. The generators are offered either open or enclosed and have a 4-point mounting system to reduce vibrations. The company also provides an App for tracking the generator or vehicle location while staying up-to-date on metrics such as temperature, tank levels, and engine performance. The company distributes its products worldwide through distributors and service dealers, and its mobile generators are used in several areas, including on medical vehicles, food trucks, and luxury coaches.

-

-

-

-

-

Sy-Klone International

Flexible Hose Kit

Company Overview

Sy-Klone International was established in 1986 and is headquartered in Jacksonville, Florida, U.S.A., is a manufacturer and supplier of precleaning and filtration systems for various industrial applications. The company's product folio includes Vortex MAX-powered pre-cleaners, XLR XLR-powered pre-cleaners, RESPA air quality systems, adaptation kits, and, filters that are used on HVAC units and engines in heavy equipment, mining, agriculture, fire and rescue, and, military sectors. The company holds ISO 23875 international standard certification, owns more than 100 patents, and achieved the Sterling Manufacturing Business Excellence award and Coast Manufacturers Association’sWorkforce Development award.

-

-

-

-

-

Air Cleaning Specialists, Inc.

Ultra Flex Steel Hose

Company Overview

Air Cleaning Specialists Inc., established in 1979 and based in Missouri, USA, is a manufacturer and supplier of air filtration systems. Its product portfolio includes air filtration systems and cleaners with various filter sizes and specifications. The company also offers initial consultation, installation, maintenance, filter service life at optimum level with customer service, and technical support. Its products have various applications, which include diesel exhaust, odor control, and general air quality improvement.

-

-

-

-

-

Witzenmann USA LLC

FLEXIBLE METAL HOSES

Company Overview

Witzenmann USA LLC, established in 1854 and based in Pforzheim, Baden-Württemberg, Germany, is a manufacturer and supplier of flexible metal hoses. The company's product range includes expansion joints, metal bellows, pipe supports, and the FLEXPERTE software application. These products are designed for absorbing motion, transporting media, and decoupling vibrations. It primarily serves industries such as automotive construction, plant engineering and construction, energy generation, and aerospace. The company also offers solutions for bearing and guiding pipelines, and the use of its FLEXPERTE software for dimensioning and presenting expansion joints and metal hoses.

-

-

-

-

-

Pneumatic Conveying, Inc.

Flex Hoses

Company Overview

Pneumatic Conveying, Inc., established in 1979 and headquartered in Ontario, California, is a manufacturer and supplier specializing in pneumatic conveying systems of dry bulk solids for the processing industries. The company's product offerings include pellet whisper loader kits, powder whisper loader kits, blower packages, control panels, and conveying adapters. These products are utilized in various industries, including food, pharmaceuticals, nutraceuticals, chemicals, and agriculture. The company boasts a diverse clientele, including companies like Nestle, Kraft, Bimbo Bakeries, Pepperidge Farm, and Starbucks Coffee.

-

-

-

-

-

Metraflex Co.

Flexible Metal Hose

Company Overview

Metraflex Company was founded in 1958 and is based in Chicago, Illinois. Metraflex is a distributor of piping specialty products to the commercial HVAC industry among others. These are used in vibration isolation, noise dampening, protection against thermal expansion and contraction, pipe alignment, seismic movements, pump connections, and flow conditioning. Metraflex Product categories include metal expansion joints, rubber expansion joints, Metraloop, seismic breakaway hangers, energy saving pump connectors, flexible metal hoses, flexible couplings, valves, compensators, strainers, air vents, pipe guides, anchors, wall penetration seals, and fittings.

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

BISCO Enterprise

Heavy Duty Flexible Hose with Grounding Wire

Distributor Overview

BISCO Enterprise, founded in 1974 and located in Schaumburg, Illinois, is a distributor of dust collectors and air cleaning and purifying equipment. The company’s diverse range of products includes paint booths, ducting, fume extractors, fume arms, and replacement air filters. These products are used in industrial and commercial settings, aiming to ensure air quality, worker safety, and compliance with environmental standards. The company’s products are utilized in industries such as manufacturing, automotive, woodworking, and chemical processing to control fumes, particles, and contaminants and maintain clean and safe working environments.

-

-

-

-

-

Coral S.p.a.

Flexible Hose

Manufacturer Overview

Depureco Industrial Vacuums SRL, established in 1972 and headquartered in Volpiano, Italy, is a designer, manufacturer, and distributor of industrial vacuum cleaners. The company's products include vacuum cleaners for dust extractors, cement plants, and flour and grain mills. It also offers centralized vacuum systems and custom industrial vacuum cleaners which find ideal applications in various industrial production lines to eliminate any processing residue. The company also offers services, including technical support available on-site and over phone, operator training, and the supply of spare parts.

-

-

-

-

-

Plastem

TUBE WITH HEAT RESISTANCE

Manufacturer Overview

Plastem, based out of Wattignies, France, is a specialist designer, manufacturer, and direct supplier of injection-molded technical parts. The company offers thousands of parts and products to individual trade professionals and commercial buyers through its online store, including plastic caps for steel, PE, and PVC tubes, heat-resistant silicone plastic plugs, and self-adhesive bumper pads that are used in various applications by plumbers, electricians, and HVAC experts, among others. It also offers consultation to clients who are looking to create a custom product.

-

-

-

-

-

FITOK Group

Multipurpose Push-on Hoses

Manufacturer Overview

Fitok Group, established in 1988 and located in Wuhan, Hubei, is a manufacturer that produces general instrumentation valves and fittings. The company offers a wide range of products, including instrumentation valves, fittings, manifolds, filters, and 2D/3D drawings. It also offers hoses, tubing, sampling systems, tooling, and subsea Products. Its product acts as a barrier, preventing active compounds from reacting with or adsorbing to the stainless steel. The company has received ISO 9001:2015, ISO 15848, and ASTM F1387 certification. It serves a wide range of industries such as oil and gas, petrochemicals, thermal power, nuclear power, and hydrogen applications.

-

-

-

-

-

Power Wash Italiana srl

Hoses

Manufacturer Overview

Power Wash Italiana srl, based in Guidizzolo, Italy, is a manufacturer of high pressure washers and accessories. The company designs and manufactures hot water and cold water high pressure washers, as well as boilers-hot boxes and special washing machines. It also provides various accessories for washing machines, such as nozzles, guns and hoses. The special machines come in different pressures and flow rates, united by the methods of construction and the components.

-

-

-

-

-

Colex International Ltd.

Dual Containment Hose

Manufacturer Overview

Colex International Ltd., founded in 1992 in Market Harborough, United Kingdom, is a manufacturer of various plastic fabrication products. The company offers products such as flexible thermoplastic hose and tube, including industrial hose and tube, as well as pneumatic hose and tube for plastic fabrication. It holds ISO 9001 quality certifications and the product range offers various advantages, including flexibility, durability, and chemical resistance, making them suitable for numerous applications. These products find applications in industries such as manufacturing, pneumatics, and plastic fabrication.

-

-

-

-

-

TÉCNICAS E INGENIERÍA DE PROTECCIÓN, SAU

Rubber Lay Flat Hose

Manufacturer Overview

TÉCNICAS E INGENIERÍA DE PROTECCIÓN, SAU, founded in 1953 and based in Barcelona, Spain, is a manufacturer of lay-flat hoses and fire equipment. The company manufactures lay-flat hoses and fire equipment like firefighting nozzles for different industries, such as firefighting & emergency, agriculture and water wells. Additionally, it also offers a wide range of couplings and hose related accessories. Its product portfolio includes brands like ARMTEX and BLINDEX in the hose range, and VIPER in the fire nozzle range.

-

-

-

-

-

FPZ, Inc.

Flexible hose

Manufacturer Overview

FPZ, Inc., founded in 1975 in Concorezzo, Italy,, is a manufacturer of industrial fluid and gas handling equipment. The company produces various products category, including regenerative blowers, rotary vane vacuum pumps, and side channel blowers. These solutions offer benefits such as efficient fluid and gas movement, compact design, and optimal performance, assisting in enhanced process efficiency. Industries spanning wastewater treatment, medical equipment, and pneumatic conveying use the solutions for various applications. Its specialty in fluid handling technology allows for tailored solutions to address specific customer needs by delivering precise fluid and gas handling equipment that optimizes various industrial processes.

-

-

-

-

-

ContiTech Deutschland GmbH

Water Hose

Manufacturer Overview

ContiTech, established in 1871 with operations in more than 40 countries, is a manufacturer of rubber and plastic products serving the machine and plant engineering, mining, agriculture, and automotive markets. The company has numerous products, including air spring systems, anti-vibration systems, coated fabrics, compensators and connecting pipes, and conveyor belt systems. ContiTech, with over a century of experience, provides custom aggregate solutions to clients, including asset inventory management, assembly and installation tools, conveyor belt system consulting, and custom production.

-

-

-

-

-

norelem Normelemente GmbH & Co. KG

Coolant hose

Manufacturer Overview

Normelemente KG, established in 1958 and based in Markgroningen, Baden-Wuerttemberg, is a German manufacturer and supplier that specializes in standard parts and machine components. Norelem offers an extensive catalog of more than 70,000 products, catering to the needs of engineers and designers in various projects. Their product range includes clamping technology, measuring and testing components, electromechanics, systems and components for machine and plant construction, and material handling and transport solutions. These products find applications in diverse engineering fields, such as automotive, aerospace, machinery, and robotics sectors.

-

-

-

-

-

Theodor Henrichs GmbH

Reinforced hose

Manufacturer Overview

Theodor Henrichs GmbH, founded in 1952 and based in Germany, is a manufacturer of hose reels, boilers, and high-pressure cleaners for various industries. The company's product line features hot water production systems, hose handling equipment, and specialized metalworking services. It offers expertise in numerous sectors, including cleaning techniques for factories and airports, hygienic systems for the food processing industry, and renovation solutions for large-scale projects. Theodor Henrichs GmbH's metalworking services deliver customized sheet metal solutions, which include laser cutting, stamping, and bending services.

-

-

-

-

-

Longer Precision Pump Co., Ltd,

Peristaltic Pump Silicone Tubing Type

Manufacturer Overview

Longer Precision Pump Co. Ltd. was founded in 1997, in China, as a manufacturer of fluid transfer and handling devices. The company provides Peristaltic Pumps of various types like Basic, Intelligent, Dispensing and Flow Rate, and OEM Peristaltic Pumps such as the Hemodialysis pump that is used for pumping fluids in dialysis machines. Syringe pumps and Micro Gear Pump have uses in laboratories and the Micro Piston Pump has applications for device fluid sampling. The Longer Precision Pumps serve the pharmaceutical, medical, laboratory, and environmental monitoring industries.

-

-

-

-

-

VUOTOTECNICA S.r.l.

Flexible hoses

Manufacturer Overview

VUOTOTECNICA S.r.l. is an ISO 9001:2015-certified Italian manufacturer of vacuum systems for industrial applications that was established in Brivio, Lecco, in 1975. The company’s product lineup includes vacuum cups such as bellows or flat models, rotary vane vacuum pumps, and vacuum valves such as solenoid valves. It also offers vacuum grippers, and related accessories such as vacuum suction spiders and vacuum conveyors. The company’s products are used by clients in the industrial manufacturing, industrial packaging, and industrial automation sectors.

-

-

-

-

-

AIRpipe Corporation

Flexible Hose

Manufacturer Overview

AIRpipe Corporation is a manufacturer and distribution of aluminum-fabricated industrial products that was established in Ningbo, China in 1997. The company primarily produces fittings designed for connecting pipes or other components, pipe systems in various grades (e.g. corrosion-resistant), and valves for controlling the flow or pressure along pipe systems. It also offers related accessories such as filters, couplings, and regulators. Aside from its products, the company provides various engineering services to its clients including custom product design, installation, and testing.

-

-

-

-

-

Albert Fezer Maschinenfabrik GmbH

Vacuum hose

Manufacturer Overview

Albert Fezer Maschinenfabrik GmbH, founded in Germany in 1933, is a manufacturer of vacuum lifters. The company's product portfolio includes customizable attachments for lifting fragile or irregularly shaped items, standard vacuum lifters, and heavy-duty vacuum lifters for lifting substantial loads, ideal for industrial applications. It also provides maintenance and support services to ensure the continued performance and longevity of our equipment. The company has international and long-term trading partners in more than 40 countries.

-

-

-

-

-

M&C TechGroup Germany GmbH

Tube PTFE

Manufacturer Overview

M&C TechGroup Germany GmbH, established in 1985 and headquartered in Ratingen, Germany, is a manufacturer of gas sampling, gas conditioning, and process control solutions. The company offers a wide range of products such as gas sample probes, heated lines, pumps, coolers, and more. It also provides filters, analyzers, temperature controllers, and gas conditioning systems. Its gas sample probe SP10 can withstand temperatures of up to 180 °C [356 °F]. The company serves several industries such as glass industry, chemical industry, environmental technology, power plants, and more.

-

-

-

-

-

SAF S.r.l.

Tubes

Manufacturer Overview

SAF S.r.l. is a manufacturer of silencers, filters, and fittings for industrial automation that was established in Rotkreuz, Switzerland, in 1978. The company offers rotary actuators in stainless steel or aluminum materials, metal silencers or mufflers for pneumatic systems, and sintered filters. It also offers fittings and related accessories fabricated from plastic, stainless steel, brass. The company’s products are used mainly by clients in the automotive and semiconductor industries, and in the industrial manufacturing sector.

-

-

-

-

-

FINI

Air hoses

Manufacturer Overview

FINI is a manufacturer of air compressors and related accessories that was established in Robassomero, Torino, Italy, in 1952. The company’s product lineup includes rotary screw compressors for heavy duty applications, piston compressors for standard industrial operations, and silent compressors for use in laboratory or medical facilities. It also offers related air treatment accessories such as filters, tanks, and hoses. The company’s products are commonly used in the manufacture of laboratory and research equipment, pneumatic tools, and industrial machinery.

-

-

-

-

-

igus

Pneumatic hoses

Manufacturer Overview

Igus, founded in 1964 and headquartered in Cologne, Germany, is a manufacturer of energy chain systems and polymer plain bearings. The company manufactures low-wear and high-performance polymers using injection mold processing. It also produces motion plastic products made of lubrication-free plastic, including energy chains, cables, and lead screw technology. The company offers services like installation, custom solution, and online resources. It serves the automotive, packaging, agriculture, and other industries, and maintains several certifications, including ISO 9001, IATF16949, and RoHS.

-

-

-

-

Manufacturer Overview

FIPA, established in 1985 and headquartered in Munich, Germany, is a manufacturer of vacuum technology and end-of-arm tooling solutions. The company offers products connected with all aspects of material flow systems. It provides vacuum technology products like peripheral hardware for the generation and control of vacuums, hoses, fittings, lifting technology for lifting and conveying loads and end-of-arm tooling like gripper systems for the handling of workpieces. It also offers tailored solutions for special requirements. The company's products are mainly for plastics, sheet metal, packaging and general industries. It also offers training courses and seminars, equipment rental and installation services.

-

-

-

-

-

Prevost UK Ltd.

Spiral hose extension

Manufacturer Overview

Prevost UK Ltd. , based in Annecy-le-Vieux, France, is a designer and manufacturer of compressed air and fluid distribution solutions. Its product range includes quick safety couplings, piping networks, filtration solutions, and pneumatic equipment. Notably, the company introduced the industry's first push-button coupling with a square button and launched the first composite "anti-hose whip" safety coupling, and the pure aluminum compressed air network called Prevost Piping System (PPS) in 2017. Its offerings are utilized for safety, efficiency, and the preservation of air and fluid quality.

-

-

-

-

-

Hebei Qianli Rubber Products Co., Ltd

Flexible Braided Metal Hose

Manufacturer Overview

Hebei Qianli Rubber Products Co., Ltd, founded in 1993 and headquartered in Jingxian County, China, is a manufacturer and supplier of hose products. The company manufactures and exports high pressure, medium pressure and low pressure hydraulic hoses in customizable sizes and specifications. This product range includes rubber or thermoplastic inner tube type, spiral or braid reinforcement type and steel or fiber reinforcement type of hoses. It also provides rubber hose fittings and associated accessories along with it. The company has obtained ISO 9001 certification, and its products comply with the American SAE, German DIN and Russian GOST standard.

-

-

-

-

-

TECHNOFLEX CORPORATION

Flexible Hoses

Manufacturer Overview

TECHNOFLEX CORPORATION is a Japanese ISO 9001 certified manufacturer of flexible metal hoses and expansion joints established in 2001 and based in Taito-ku, Tokyo. The company produces flexible hoses, expansion joints, and cleaning equipment components. These include coupling, flange, or threaded flexible hoses, rectangular or thick bellows, formed bellows, and convoluted fluoroplastic hoses. The company’s products are mainly used by client manufacturers of construction and water pipes, with additional applications in the shipbuilding, semiconductors, power distribution sectors.

-

-

-

-

-

IHARA SCIENCE CORPORATION

Hoses/Pipes

Manufacturer Overview

IHARA SCIENCE CORPORATION, established in 1941 and headquartered in Takanawa, Minato ward, Tokyo, is a manufacturer specializing in bite-type tube fittings and other high-pressure fittings designed for hydraulic applications. The company offers a wide range of product portfolios including fittings, pipes, valves, and related components. These quality products serve critical roles in various industries, including railway vehicles, semiconductor manufacturing, measurement instruments, construction machinery, and more. The aim of the company is to provide optimal piping systems tailored to meet the specific needs and demands of diverse applications.

-

-

-

-

-

DAIDOH TOKUSHU KOGYO CO.,LTD.

FLEXIBLE HOSE

Manufacturer Overview

Daidoh Tokushu Kogyo Co., Ltd., founded in 1977 with headquarters in Tokyo, Japan, is a manufacturer of flexible industrial hoses, expansion joints, and connectors. The company's product line includes resin-based hoses, silicon-based hoses, sanitary hoses, non-metal bellows, and titanium flexible hoses. These products are used in industrial equipment, connector hoses for process manufacturing equipment, and connector hoses for hospital and medical equipment. The company serves many industries, including food services, food processing, chemical processing, and pharmaceutical processing.

-

-

-

-

-

Fuji Koatsu Flexible Hose Co., Ltd.

Flexible Hose

Manufacturer Overview

Fuji Koatsu Flexible Hose Co., Ltd. established in 1947 in Hikari City, Yamaguchi Prefecture, is a manufacturer and supplier of hydraulic piping parts. The company's product range includes flexible hoses, joints, bending pipes, Meiji Flex Composite Hoses, and oil cleaners. These products are essential for fluid transfer in applications ranging from industrial construction machinery to factories. They serve industries such as manufacturing, construction, and marine. Beyond producing these items, the company offers custom product design, testing for quality assurance, pressure resistance inspection, and customer support services.

-

-

-

-

-

Watson-Marlow Fluid Technology Group

Aflex Hose

Manufacturer Overview

Watson-Marlow Fluid Technology Group, founded in 1956 and located in Falmouth, United Kingdom, is a manufacturer of dispensing and peristaltic fluid pumps. The company’s products include metering pumps, water pumps, electric peristaltic pumps, precision tubing, and associated fluid path components. Their products find specific applications in pharmaceuticals, food and beverage, water and wastewater treatment, and chemical processing. Watson-Marlow holds certifications such as ISO 9001 and ISO 13485 that adhere to stringent control measures, ensuring that their products meet or exceed industry standards.

-

-

-

-

-

NANGOKU FLEXIBLE HOSE INDUSTRY CO., LTD

Flexible Hose

Manufacturer Overview

NANGOKU FLEXIBLE HOSE INDUSTRY CO. LTD. is a manufacturer of flexible hoses and bellows founded in 1971 and headquartered in Osaka, Japan. The company mainly produces flexible joints and pipe expansion joints. These products are designed to support a wide range of gas and liquid transport system lines used by the steelmaking, chemical, and industrial sectors. It also offers lap joints to support different steel types and lengths, using a proprietary NFK flare-forming process for flanging. The company has obtained various certifications, including ISO 9001, Japanese hazardous materials regulations, maritime classification societies, and Japanese welding standards.

-

-

-

-

-

Allto Pipeline Equipment Co.,Ltd

Flexible Metal Hose

Manufacturer Overview

Allto Pipeline Equipment Co. Ltd., established in 1996, is a Chinese manufacturer based in Zengcheng, Guangzhou, specializing in pipe fittings as well as water supply and drainage equipment. The company offers expansion bellows and joints, dismantling joints, and flange flexible hoses. The company also produces air duct compensators and power transmission joints. Adhering to global standards, including those set by the American National Standards Institute (ANSI) and Deutsches Institut für Normung (DIN), the company serves international markets, including the United States, Europe, and the Middle East. Its products find applications in various sectors, such as fire protection, petroleum, and sewage treatment.

-

-

-

-

-

Polyhose India Pvt Ltd

Flexible Hose

Manufacturer Overview

POLYHOSE India Pvt., Ltd., is a manufacturer of fluid conveyance products, founded in 1996 and headquartered in Chennai, Tamil Nadu, India. The company is a global diversified industrial conglomerate specializing in design, development, and distribution of energy conveyance products. With modern manufacturing and state-of-the-art facilities, it offers a wide range of products to multiple industries, including hydraulic, industrial, composite, stainless steel flexible hoses and fluid connectors. It has established global footprints with presence in North and South America, Europe, Middle East, Southeast Asia, South Africa and Australia. Today it engages more than 3500 employees in its worldwide operations.

-

-

-

-

-

DITECH,LTD.

Portable moisture detector

Manufacturer Overview

Ditech, Ltd. is a manufacturer of sensors and detectors for industrial applications that was established in Osaka, Japan, in 1975. The company produces liquid transmitters such as turbine flow meters and vibrating viscometers, and liquid detectors such as dissolved oxygen meters and portable moisture detectors. It also offers various level transmitters and switches, including conductive, capacitive, and ultrasonic model types. The company’s products are primarily used by clients in the food and beverage, petrochemical, and environmental industries.

-

-

-

-

-

Tyco Fire Protection Products

Flexible Hose

Manufacturer Overview

Tyco Fire Protection Products, based in Landsdale, Pennsylvania, serves as a manufacturer and supplier of diverse fire suppression systems for various applications spanning commercial, industrial, and residential sectors. Its product line encompasses extinguishing agents, sprinkler systems, and valves. The company also offers piping products, firefighting equipment, and services. Its water-based fire products range from automatic sprinklers, system valves, to electrical devices. Its global technology portfolio comprises several brands, including TYCO, ANSUL, and GRINNELL.

-

-

-

-

Manufacturer Overview

Nicem, established in 1970 and headquartered in Bergamo, Italy, is a manufacturer and supplier of industrial machines and plants. The company provides various solutions that include enameling, vibro-fin hinging, and furnaces for abrasive disks. Its individual products include silicone rubbers for spin casting, glass dryers and polishers for professional catering services, and enamel ovens. It welcomes consultation on complete industrial or commercial processing lines and can provide custom-designed, engineered, and manufactured turnkey systems. It also provides practical and theoretical training courses for the correct use of its machines, plants, and consumables.

-

-

-

-

GUANGDONG ZHULI CASTING MATERIALS TECHNOLOGY Co., Ltd.

High Pressure Composite Hose for Oil Gas Water

Manufacturer Overview

GUANGDONG ZHULI CASTING MATERIALS TECHNOLOGY Co., Ltd was founded in 2012, and its headquarters is in Zhuhai, Guangdong, China, as a manufacturer of foundry resins and casting materials. The production process has been effectively supervised and controlled per the ISO 9001-2008 quality management standards. A strong rapport has been established with over 300 clients with expertise in various casting processes, including gray iron casting, ductile iron casting, carbon steel, copper casting, aluminium casting, and non-ferrous metal castings.

-

-

-

-

-

Festo Corporation.

Plastic tubing

Manufacturer Overview

Festo Corporation, established in 1925 and headquartered in Esslingen, Germany, is a supplier of automation technology and technical education and is ISO 9001, ISO 13485, and ISO14001 certified. It has around 33,000 catalog products, customized components, and ready-to-install solutions, including grippers, motors, and sensors used in industrial and process automation. The company won the German Future Award in 2010 and serves 300,000 customers worldwide, while its education division provides training solutions for 56,000 industrial companies and educational institutions. It registered €3.81 billion in the 2022 financial year and is available in around 60 countries, with 2,600 patents worldwide.

-

-

-

-

-

GRUPO DE INCENDIOS

Hoses

Manufacturer Overview

Grupo de Incendios, headquartered in Soria, Spain, is a manufacturer that designs, develops, sells, and produces fire protection and prevention equipment. The company offers a wide range of products, including fire extinguishers, fire hoses, fire cabinets, and fire hydrants. It also offers sprinklers, fittings, nozzles, hoses, and valve control. Its products can provide access to water and other fire suppression materials, helping to prevent the spread of fire to other areas. The company has achieved CE and A21/000063 certifications. It serves industries such as commercial, industrial, and residential buildings.

-

-

-

-

-

Cepillos SACEMA

INDUSTRIAL AIR/WATER HOSE

Manufacturer Overview

Cepillos Sacema is a manufacturer of industrial sweepers and brushes established in 2020 and based in Gijón, Spain. The company offers standard industrial brushes and brush heads for manual or automated cleaning processes, specialized brushes such as for solar panels or HVAC systems, and motorized belts for removing sludge in wastewater treatment plants. It also offers custom design and production services for unique projects. The company’s products are commonly used in the industrial and agricultural sectors, with additional applications in urban municipal projects.

-

-

-

-

-

SovPlym Ltd.

Flexible heat-resistant hoses

Manufacturer Overview

SovPlym Ltd. is based in Saint Petersburg, Russia, and is a manufacturer of industrial filtration and ventilation systems established in 1989 as a joint venture with Sweden’s Plymovent Group. The company’s products include vehicle exhaust extraction devices for venting exhaust from close spaces like garages or workshops, local extraction ventilation systems for capturing and removing fumes or dust from a workspace, and oil mist pre-separators and filters for exhaust from metalworking machines. The company is ISO 14001 certified and operates internationally, with branch offices in Uzbekistan, Israel, and India.

-

-

-

-

-

Nex Flow Air Products Corp.

Rigid Flex Hose

Manufacturer Overview

Nex Flow Air Products Corp. was established in 1993 and based in Ontario, Canada, as a manufacturer of compressed air-operated products and accessories. Its products include air amplifiers and knives, air-operated conveyors, safety air blowoff guns, and air optimization products. It also manufactures compressed air accessories like stainless steel shim kits and temperature sensing labels. Its products comply with NEMA standards and are utilized for pharmaceutical, metalworking, general manufacturing, and automotive industries across North America, Thailand, Malaysia, India, and Indonesia. The company partnered with companies like Samsung, Ford, Nestle, and Toyota. It acquired NEMA 12, NEMA 3R, and NEMA 4-4x certifications.

-

-

-

-

-

Alfa Laval Corporate AB

Hygienic tubes

Manufacturer Overview

Alfa Laval Corporate AB was founded in 1883 and headquartered in Lund, Sweden. Alfa Laval serves energy, utilities, home, personal care, food, dairy, beverage, marine, transportation, pharmaceutical, biotech, water, and wastewater industries. Alfa Laval provides heat transfer, separation, and fluid handling products and solutions worldwide. Alfa Laval operates in three divisions: Energy, Food & Water, and Marine. Alfa Laval offers oil & gas-fired steam and composite steam boilers, exhaust gas economizer, and ballast water treatment systems, and exhaust gas cleaning products. Alfa Laval also provides sensing and control, cleaning validation, condition monitoring, agitators, tank, powder mixers, fittings, and tubes, as well as wall mounted cleaning nozzles, rotary jet and heads; and tank accessories and covers.

-

-

-

-

-

Plymovent Corp.

Flexible Extraction Hose

Manufacturer Overview

Plymovent Corp., established in 1975 and headquartered in Cranbury, New Jersey, USA, is a manufacturer of air purification and extraction systems. The company produces various products, including vehicle exhaust extraction systems, welding fume extraction solutions, and industrial dust collection equipment. These solutions offer benefits such as improved air quality, increased worker safety, and regulatory compliance, assisting in healthier and safer workplaces. Industries spanning automotive repair, manufacturing, and construction use the purification systems for effective air pollution control. Its specialization in air filtration technology allows for tailored solutions to address specific air quality challenges that enhance occupational health and environmental protection.

-

-

-

-

-

HANSA-FLEX

COMPRESSOR HOSES

Manufacturer Overview

HANSA-FLEX, been in business since 1962 and headquartered in Bremen, Germany, is a manufacturer of various types of hydraulic products and services. The company produces hoses, hose fittings, couplings, pipe fittings, and ball valves. It also fabricates hydraulic components, flanges, adapters, and pipes. The variants of its hoses, braided hoses, are oil, high-temperature, ozone, and weather-resistant. It has more than 80,000 parts relating to all aspects of hydraulics. It could also configure the customers’ hose lines based on their required specifications.

-

-

-

-

-

KLIMAWENT S.A

Flexible conduits

Manufacturer Overview

Klimawent SA, founded in 1992 and based in Gdynia, Poland, is a manufacturer of filtering and ventilation equipment. The company offers products such as industrial fans, filtering units, and devices for contamination extraction, as well as truck snow removal systems and modular tactical shooting ranges. It offers over 300 products in seven categories and has formed over 300 fire brigades in Poland. The company also provides assembly services, including equipment assembly, installation, and employee training. Other services provided by the company are cutting and bending sheet metal using CNC machines capable of achieving positioning accuracy and repeatability of ±0.01mm/500mm.

-

-

-

-

-

WenZhou Holid Automation Equipment Co.,Ltd.

Anti Spark PU Tube

Manufacturer Overview

Wenzhou Holid Automation Equipment Co. Ltd., established in 1998 and headquartered in Wenzhou, China, is a manufacturer of pneumatic products. The company's products include industrial shock absorbers, oil dampers, and polyurethane tubes. Its oil shock absorbers and pneumatic vibrators are designed to minimize vibration and noise. It also offers air source treatment solutions, such as filter regulators and pneumatic tubes for efficient pneumatic control systems. The company's products find ideal applications in vacuum circuit breakers, tripod turnstiles, and woodworking machinery.

-

-

-

-

-

TECNICA S.r.l.

Flexible hose

Manufacturer Overview

Tecnica SRL, founded in 1984 and headquartered in Rolo, Italy, is a designer and manufacturer of air flow and filtration equipment and accessories for air conditioning systems. The company's products include flexible piping, air flow diffusers, and filtration panels. Its products are designed to increase insulation, sanitize, and provide cleaner air through materials developed in cooperation with Sanitized AG to promote antimicrobial hygiene functions that reduce the microbial and bacterial load present in air conditioning systems. Its product brands include MasterSan, PlenuSan, and FiltraSan.

-

-

-

-

-

ELECTROSTAR GmbH

SUCTION HOSE

Manufacturer Overview

Electrostar GmbH, a subsidiary of Algo Group, is based in Ebersbach an der Fils, Germany, and has been a manufacturer of vacuum, dust-free, and sanitary products since 1921. The company first introduced warm air hand dryers and has since diversified its portfolio to include the Starmix series of particulate air (HEPA) hand dryers and disinfection dispensers, as well as vacuum cleaners of many industrial options. It also produces patented disc brooms under the Haaga brand and other manual and battery-operated sweepers. The company offers custom sanitary and hospitality products based on customer requirements.

-

-

-

-

-

Detroit Flex Defense

INDUSTRIAL BRAIDED PTFE HOSE

Manufacturer Overview

Detroit Flex Defense, established in 1953 and based in Troy, USA, is an AS9100D and AWS D17.1 certified manufacturer and supplier of hose solutions. The company's product range includes industrial-grade PTFE hose, high-pressure PTFE hose, military-grade braided PTFE hose, formed PTFE/kevlar hose, and rubber/thermoplastic hose. These products are optimized for fluid and media applications. It serves industries such as defense, niche automotive, aerospace, and alternative fuels. The company provides engineering, manufacturing, fabrication, and distribution services.

-

-

-

-

-

CompuVac Industries Inc.

Flexible Braided Hose

Manufacturer Overview

CompuVac Industries Inc. is a manufacturer of stainless steel vacuum bellows, metal hoses, machined and welded assemblies that is headquartered in Fountain Valley, California and was established in 1999. The company manufactures custom products ranging from metal bellows, bellows data, flexible braided hose, bellow assemblies, and metal flanges. Its production capabilities include welding and a machine for helium leak detection. Whilst, the industry markets served by the company are aerospace, cryogenics, biomedical, and semiconductor industries.

-

-

-

-

-

PNR Italia Srl

Wash Guns & Hose

Company Overview

PNR Italia Srl is based in Voghera, Pavia, Italy, and is a manufacturer and distributor of spraying products that was established in 1968 before its acquisition by the Spraylab Group in 2018. The company offers spray nozzles for creating different spray patterns or pressure levels, such as full cone, flat fan, and fog. It also offers hydraulic, pneumatic, and twin fluid atomizer models, along with tank washing heads for cleaning or sanitizing tank exteriors. The company mainly serves clients in the chemical, water treatment, and automotive industries.

-

-

-

-

-

FRÄNKISCHE Rohrwerke Gebr. Kirchner GmbH & Co. KG

Siphon hose for plumbing

Company Overview

FRÄNKISCHE Rohrwerke Gebr. Kirchner GmbH & Co. KG., founded in 1906, is a German manufacturer and supplier headquartered in Königsberg, Bavaria, producing industrial pipes. With 19 manufacturing and sales facilities worldwide, the company offers a range of products built upon its inventions, including flexible metal and plastic electrical installation pipes and yellow drainage pipes. The company develops automotive cable protection, fluid, and thermal management systems. It also provides building technology products for drinking water, heating, and heat recovery. Drainage systems are further offered for various applications, such as gardening and landscaping, road and railway tracks, and stormwater management and treatment.

-

-

-

-

-

DAYU Irrigation Group

PVC SOFT LAYFLAT WATER HOSE

Company Overview

DAYU Irrigation Group is a manufacturer and supplier of irrigation equipment founded in 1999 and headquartered in Beijing, China. The company's portfolio encompasses products like drip tape, pipe and fittings, drippers and sprinklers, sprinkler irrigation equipment, lay-flat hose and fittings, as well as various other categories. DAYU, a state-level high-tech enterprise, collaborates with engineering and scientific institutions to address and resolve agricultural and water resource challenges in rural areas. The company provides irrigation services, which encompass the integration of water conservancy and hydropower project consulting, survey and design, as well as project general contracting and construction.

-

-

-

-

-

Sommer-Technik GmbH

pneumatic hose transparent

Company Overview

Sommer-Technik GmbH is a manufacturer and supplier specializing in manufacturing automation solutions established in 1998 in Germany. It initially introduced the first sprayers for this purpose and have since expanded its offerings to include vacuum units, gripper systems, and various handling devices. It also offers vacuum and lubricating technology, delivering products like strip lubricators and non-fogging mini-atomizers. The company's product range includes products like power vacuum ejectors, suction cups, and vacuum manometers. These offerings serve industries reliant on automation and vacuum technology for optimized manufacturing processes.

-

-

-

-

-

ITV GmbH

Polyurethane tube

Company Overview

ITV GmbH is a German manufacturer and distributor of pneumatic components for industrial applications that was established in 1980 in Bielefeld, North Rhine-Westphalia. The company primarily produces valves of different sizes, materials, and types. It also offers various fittings such as push-in fittings, compression fittings, and brass fittings. Its selection of tubes include fluoropolymer, polyamide, and polyurethane tubes. The company’s products are used mainly by the industrial processing sector, as well as by clients in power generation and municipal infrastructure.

-

-

-

-

-

PCL

Air Hose

Company Overview

PCL, founded in 1938 and headquartered in Sheffield, UK, is a manufacturer and supplier of compressed air products, air line accessories and tyre inflation equipment. The company designs and manufactures pneumatic equipment and components for industrial, petrol forecourt and automotive markets. Its product portfolio consists of air compressors, air hose, forecourt equipment, nitrogen equipment as well as air tools, couplings, hose fittings and tyre inflators. The company exports to over 100 countries through a network of agents and distributors, with manufacturing facilities in England, Germany, USA, India and China.

-

-

-

-

-

Dosanova

Cleaning hoses

Company Overview

Dosanova is an ISO 9001:2015-certified manufacturer and supplier of industrial cleaning system components that was established in 2008 in West Flanders, Belgium. The company primarily produces items for low- and high-pressure cleaning applications. These products include quick couplings or nipples, pressure washers, and nozzles with different threadings and range ratings. It also offers booster pumps and dosing systems for dispensers or public hygiene equipment. The company’s products are used mainly by clients in the food and beverage, automotive, and marine industries.

-

-

-

-

-

Ayvaz

Flexible hoses

Company Overview

Ayvaz, founded in 1948, and headquartered in Istanbul, Turkey, is a manufacturer of flexible connection parts in various types and customized designs. Its product range includes expansion joints, flexible metal hose, level controllers, steam equipment, and valves. The company also has production facilities in Bulgaria, Poland, and China, exporting to 100 countries with 13 regional offices and 252 distributors overseas. Domestically, the company's sales organization is made up of 12 district offices and 78 vendors.

-

-

-

-

-

JBC Tools USA, Inc.

Flexible Hose Ø 50 mm

Company Overview

JBC Tools, established in 1929 and headquartered in St. Louis, USA, is a manufacturer and distributor of tools for soldering and rework operations in electronics. The company is a pioneer in the manufacturing of lead free hand soldering and desoldering tools, and SMT rework equipment. The R&D driven company has developed an efficient soldering technology that has a soldering capability at lower temperatures, a greater heat transfer, and extended tip life which results in reduced cost of operation. JBC also offers electronic soldering stations, cartridges, tips, and accessories all of which comply with EC regulations and ESD recommendations.

-

-

-

-

-

Arex Industrial Technology company

Flexible Metal Hose

Company Overview

Arex Industrial Technology Co. Ltd., established in 1995, is a manufacturer and supplier based in Shijiazhuang, Hebei, China, providing industrial materials and equipment. Holding ISO 9001:2015 and China Council for the Promotion of International Trade (CCPIT) certifications, the company produces wear and erosion-resistant products, such as conveyor belts and rollers, liners, as well as slurry pipes and hoses, primarily catering to the mining industry. It also offers pipe fittings, such as plastic and metal expansion joints, designed to withstand abrasion, contamination, and impact. The company further provides metal, plastic, and rubber components for various industrial applications.

-

-

-

-

-

Vardhman Rubber Co.

Flexible Hose

Company Overview

Vardhman Rubber Co. is a manufacturer and supplier of industrial rubber products, established in 1980 and based in Central Delhi, Delhi, India. The company’s product range includes hoses for water and steam, hydraulic hose pipes for high-pressure steam and fuel, and cement grouting hoses. The company also produces oil suction hose pipes, electrical insulating mats, and silicone sheets. Diversifying further, the company extends its product line to include cotton canvas hoses, polyvinyl chloride (PVC) hose pipes, and stainless steel corrugated hoses.

-

-

-

-

-

CoreDux

Flexible Hose

Company Overview

CoreDux, established in 1972 and based in Tilburg, Netherlands, is a manufacturer and supplier of metal hoses and crucial artery systems for transporting gas and fluids. The company's product range includes high-end metal hoses with customer-specific adapters, bespoke systems, standard systems, engineered-to-order systems, and build-to-print (B2P) systems. These products are vital for industries such as High Tech, Health Tech, Aerospace, and Electromobility, primarily facilitating the transport of gases and liquids. In addition to its products, the company offers services such as black box design, white box design, feasibility checks, and prototype creation.

-

-

-

-

-

GKM Siebtechnik GmbH

Flexible inlet and outlet hose

Company Overview

GKM Siebtechnik GmbH, established in 1998 and based in Waibstadt, Germany, is a manufacturer and supplier of tumbler screening machines. The company's product portfolio includes vibrating tumbler screeners, pneumatic screening machines, and ultrasonic discharging systems. These products are used in various industries, including chemical processing, food and beverage, and the plastics and rubber industry. The company offers services including spare parts supply and replacement of worn or damaged screens on screening machines, and it sells its products to the United States, Australia, and China.

-

-

-

-

-

GeTech Srl

Braided Crystal Hose

Company Overview

GeTech S.r.l., founded in 1999, is an Italian manufacturer and supplier based in Villanova di Castenaso, Bologna, specializing in industrial technical products. Under the Flexo line, the company offers vibration control components such as antivibration feet, cylindrical mountings, and machine mounts. It also produces the Compo line for operation and leveling, including plastic and steel base components, hinges, and accessories. In addition, the company provides clamping and locking components within the Kiudo line and the HYRAX line, which consists of hammers, mallets, and pliers.

-

-

-

-

-

NAFFCO Group

Single Jacket Hose

Company Overview

NAFFCO (National Fire Fighting Manufacturing FZCO), established in 1991 and headquartered in Dubai, UAE, is a manufacturer and supplier of fire and safety equipment. Its product portfolio encompasses Life Safety Solutions, Fire Protection systems, Security systems, Firefighting Equipments, Fire Trucks, Ambulances, and Mobile hospitals, serving multiple industries. Notably, the company has received recognition through the Mohammed Bin Rashid Al Maktoum Business Award for excellence in exports and manufacturing, solidifying its name in fire safety and security solutions.

-

-

-

-

-

MOBIAK SA

Water hoses

Company Overview