10 Prism Mirror Manufacturers in 2024

This section provides an overview for prism mirrors as well as their applications and principles. Also, please take a look at the list of 10 prism mirror manufacturers and their company rankings. Here are the top-ranked prism mirror companies as of April, 2024: 1.OPTICA, 2.Sunex Inc., 3.Solaris Optics S.A..

Table of Contents

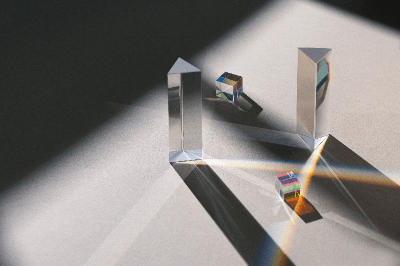

What Is a Prism Mirror?

A prism mirror is a device made of glass shaped like a triangular prism, with light-reflecting coatings applied to two sides: one on the slope and the other at a right angle.

The slope-coated type, coated on the slope, can reduce the time required for optical axis adjustment when installed at a 45° angle. The right-angle coated type, with coatings on two right-angled surfaces, can invert and reflect incoming light.

The choice of coating (e.g., broadband dielectric or metal) and base glass material depends on the intended use.

Applications of Prism Mirrors

1. Bevel Coating Type

The bevel-coated type reflects light at a 45° angle, streamlining optical axis adjustment. It's commonly used in measurement instruments like spectrophotometers.

2. Right-Angle Configuration Surface Coated Type

This type is designed for high-speed image inversion and reflecting light parallel to the optical axis in devices like interferometers. It's also effective in sunlight harvesting for light capture.

3. BBAR Coating Type

Prism mirrors with broadband anti-reflective (BBAR) coatings are ideal for low-power laser applications. They offer enhanced resistance to mechanical stresses, making them suitable for environments with severe acoustic and inertial loads.

Principle of Prism Mirrors

Right-angle configuration surface-coated types can disperse light into different wavelengths by leveraging the refractive index difference between air and glass. The mirror surface is coated with a material distinct from the glass to achieve this effect.

Coatings can be metallic or broadband dielectric, among others.

1. Metal Coating

Metal coatings, known for high light reflectivity, ensure total reflection of the incident light, altering its angle upon contact with the prism mirror.

2. Broadband Dielectric Coating

Broadband dielectric coatings minimize reflection and enhance light transmission into the glass. They work by coating the glass surface with materials of intermediate refractive indices to suppress unintended reflections.

While a single dielectric layer can reduce reflection, multiple layers with varying refractive indices can further improve transmittance.

Other Information on Prism Mirrors

1. Bonding Prism Mirrors

When bonding prisms, consider the coefficient of linear expansion to prevent cracking due to temperature changes. Flexible adhesives may mitigate this risk but require careful application for stable bonding.

2. Total Reflection

Total reflection occurs when light enters a medium of different refractive index, surpassing the critical angle, leading to light being entirely reflected.

3. Types of Metal Coatings

Various metals, like aluminum for the ultraviolet region and gold for the infrared region, are used for coatings. Base materials like BK7, N-BK7 for precision shapes, and synthetic fused silica for ultraviolet transmission are selected based on application requirements.

Materials with a low coefficient of linear expansion are preferable for temperature resilience.

List of 10 Prism Mirror Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- China

- India

- Japan

-

-

-

PFG

Optical Prisms

Manufacturer Overview

PFG Precision Optics, founded in 1977 with headquarters in the USA, is a manufacturer of optical components, assemblies, and thin-film coatings. The company's products include optical lenses, optical prisms, beam splitters, and polarizers. PFG Precision Optics' products are used for eyepieces, machine vision lens assemblies, illumination systems, and lithography inspection equipment and can be found in consumer eyewear, camera systems, and automated retail kiosk systems. PFG also provides custom lens manufacturing using all types of optical glasses, fused silica, and crystalline materials, including CaF2, Ge, and Amtir.

-

-

-

-

-

Sunex Inc.

Prism Mirror

Manufacturer Overview

Sunex is a manufacturer of optical solutions based in Carlsbad, USA. Established in 1997, the company offers a wide range of optical products tailored to meet the diverse needs of various industries. Their product portfolio includes lenses, lens assemblies, and optical modules. The company caters to various industries including automotive, consumer electronics, industrial imaging, and security systems. Additionally, the company offers optical modules that combine lenses, sensors, and other components to create comprehensive imaging solutions.

-

-

-

-

-

Thorlabs, Inc

Prism Mirror

Manufacturer Overview

Thorlabs, Inc, established in Newton, NJ in 1989, is a manufacturer of photonics equipment for research, manufacturing, and biomedical applications. Their product portfolio includes optical components, for use in imaging, sensing, and spectroscopy applications, spectrometers and analyzers used for research and industrial applications, fiber optic components and photomultiplier tubes, and imaging devices that capture and measure light signals for diverse applications in scientific research. The company has sales offices in the United States, United Kingdom, Sweden, China, and Brazil.

-

-

-

-

-

CHUO PRECISION INDUSTRIAL CO.,LTD.

Prism

Manufacturer Overview

CHUO PRECISION INDUSTRIAL CO., LTD. (Chuo Seiki Kabushiki Kaisha), founded in 1955, is a Japanese manufacturer and supplier headquartered in Chiyoda-ku, Tokyo, specializing in precise positioning units as well as optical machines and equipment. The company’s portfolio includes automatic and motorized stages and actuators, manual mechanical stages, stage accessories, and controllers. Automatic stage applications include sample table of laser repair and mapping systems, whereas manual stage applications encompass camera position adjustment for glass substrate and/or film inspection systems and prober position adjustment. Further offerings include microscopes and tool scopes, automation products for microscopes, as well as optical accessories, components, and instruments.

-

-

-

-

-

Nippon Electric Glass Co., Ltd.

Electronic Products

Manufacturer Overview

Nippon Electric Glass Co., Ltd. (NEG) is a glass technology products manufacturer originally founded in 1949 and headquartered in Otsu, Shiga. The company specializes in glass for tech and computing applications, particularly for flat-panel displays (FPDs). Their product portfolio includes substrates for FPDs and liquid crystal displays (LCDs), organic light-emitting diodes (OLEDs) and touch panels for smart devices. Other products include high modulus glass fiber, heat-resistant glass and chemically strengthened glass. NEG primarily serves clients in the digital display, automotive, and information technology markets.

-

-

-

-

-

OPTICA

Optical Prisms

Manufacturer Overview

OPTICA is a manufacturer of precision optics and polymer optics products. The company is based in Karnataka, India and is founded in 1985. The company product portfolio includes precision optics and polymer optics, optical instruments, sight systems, precision plastic molds for clear parts & molded clear parts, and product assemblies. The company supports Medical, Aerospace, Astronomy, Automation, Research & development Labs, Infrated Optics, and large-size schileren system for wind tunnels. The company also work with each customer as a partner from the initial concept drawing to prototype sample to production and support technically.

-

-

-

-

-

Solaris Optics S.A.

RIGHT ANGLE PRISMS

Manufacturer Overview

Solaris Optics S.A., founded in 1991, is an optical product manufacturer based in Józefów, Poland. Certified with ISO 9001:2015 and TÜV Rheinland, the company produces a range of lenses, such as aspheric, cylinder, and spherical lenses, commonly used in imaging systems, such as cameras, microscopes, and projectors. The company also offers custom metallic and dielectric mirrors for laser systems, sensors, and telecommunication devices. It extends its offerings to include optical windows for optical system protection, wedges that function as beam steering elements, and dispersion and reflection prisms in various materials and shapes.

-

-

-

-

-

WTS PHOTONICS CO., LTD

Prism Mirror

Manufacturer Overview

WTS PHOTONICS CO., LTD. is a manufacturer and supplier of optical components and laser crystals that was established in 2009 and is headquartered in Fuzhou, China. The company produces many optical components, including lenses, mirrors, filters, and prisms. Its products such as high accuracy corner cube prisms, triplet achromatic lenses, precision optical glass achromatic lenses (doublets), high accuracy l-bar mini prism, high precision glass x-cube and RGB prisms, and YAG laser crystal are used by a number of industries, as diverse as laser, semiconductor, and imaging industries. The company’s solutions include optical processing, optical coating, optical assembly, and optical design.

-

-

-

-

-

Ecoptic

Prism Mirror

Manufacturer Overview

Ecoptic, founded in Changchun, Jilin in 2000 is a manufacturer of precision optical components, such as spherical mirrors, aspheric mirrors, and filters. The company's product portfolio includes Optical Cylindrical Lenses, Optical Dome, Optical Mirrors, Optical Prism, and Optical Spherical Lenses. The company serves markets including Medical and Healthcare, Aerospace and Defense, Consumer Goods, Industrial Manufacturing and Construction and Building. The company provides services such as Product Selection Guidance, Engineering Support, New Product Design and Development and Custom Manufacturing.

-

-

-

-

-

Bohr Optics Co.,Ltd

Right Angle Prism

Company Overview

Bohr Optics Co., Ltd. is based in Changchun, Jilin, China, and has been a manufacturer and distributor of scientific optical components since its inception in 2016. The company offers various optical products such as optical spherical lenses, optical ball lens, cylindrical lens, anti-reflection coating, as well as corner cube prism. The company operates in compliance with ISO 9001:2015 and RoHS quality standard, and offers OEM services for customers through eight production lines.

-

-

Prism Mirror Manufacturer Ranking

*Including some distributors, etc.Ranking as of April 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | OPTICA |

28.0%

|

| 2 | Solaris Optics S.A. |

12.0%

|

| 3 | Bohr Optics Co.,Ltd |

12.0%

|

| 4 | WTS PHOTONICS CO., LTD |

12.0%

|

| 5 | Sunex Inc. |

12.0%

|

| 6 | Nippon Electric Glass Co., Ltd. |

8.0%

|

| 7 | CHUO PRECISION INDUSTRIAL CO.,LTD. |

8.0%

|

| 8 | Ecoptic |

4.0%

|

| 9 | Thorlabs, Inc |

4.0%

|

Derivation Method

The ranking is calculated based on the click share within the prism mirror page as of April 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- Nippon Electric Glass Co., Ltd.: 1,687

- WTS PHOTONICS CO., LTD: 150

- Ecoptic: 120

Newly Established Company

- Bohr Optics Co.,Ltd: 2016 (8 years ago)

- Ecoptic: 2004 (20 years ago)

- Thorlabs, Inc: 1989 (35 years ago)

Company with a History

- Nippon Electric Glass Co., Ltd.: 1949 (75 years ago)

- PFG: 1976 (48 years ago)

- OPTICA: 1985 (39 years ago)

Prism Mirror Manufacturers in United States

*Including some distributors, etc.

Global Distribution of Prism Mirror Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

3 | 33.3% |

China

China

|

3 | 33.3% |

Japan

Japan

|

2 | 22.2% |

India

India

|

1 | 11.1% |