11 Hydrogen Gas Generator Manufacturers in 2024

This section provides an overview for hydrogen gas generators as well as their applications and principles. Also, please take a look at the list of 11 hydrogen gas generator manufacturers and their company rankings. Here are the top-ranked hydrogen gas generator companies as of April, 2024: 1.PerkinElmer Inc., 2.CP Lab Safety, 3.LNI Swissgas.

Table of Contents

What Is a Hydrogen Gas Generator?

A hydrogen gas generator is a device designed to produce hydrogen gas. It allows for the generation of hydrogen gas without the need for gas cylinders. Hydrogen gas finds applications in various fields, including research experiments, analytical instruments, and as fuel for fuel cell vehicles.

Uses of Hydrogen Gas Generators

Hydrogen gas is utilized in a wide range of applications, spanning from research and industrial sectors to general use.

1. Research Applications

Hydrogen gas serves as a carrier gas in gas chromatography (GC), as well as a fuel gas in experiments. It is commonly used as a fuel for hydrogen flame ion detectors (FID).

2. Industrial Applications

In industrial settings, hydrogen gas plays a significant role in various processes. This includes the desulfurization of petroleum products, serving as a raw material for ammonia synthesis, and acting as a hydrogen source for applications such as diamond synthesis via microwave plasma CVD and thin-film silicon production. Hydrogen and oxygen or air gas mixtures are used in burners due to their ability to maintain a stable flame at high temperatures without soot contamination.

Other promising applications involve the cleaning of silicon wafers using hydrogen-infused water, as well as the practical implementation of hydrogen-reduced ironmaking technologies aimed at reducing carbon dioxide emissions.

3. Fuel and General Use

Hydrogen gas holds potential in fuel cells for automobiles and household batteries. It is also employed in hydrogen fuel engines for power generation facilities and internal combustion engines in vehicles, contributing to the realization of carbon-neutral societies.

4. General Use

Hydrogen gas inhalers find applications in industries like cosmetics, medicine, sports, and relaxation.

Principle of Hydrogen Gas Generators

Hydrogen gas generators can be categorized based on the method they employ to produce hydrogen gas.

1. Electrolysis of Water

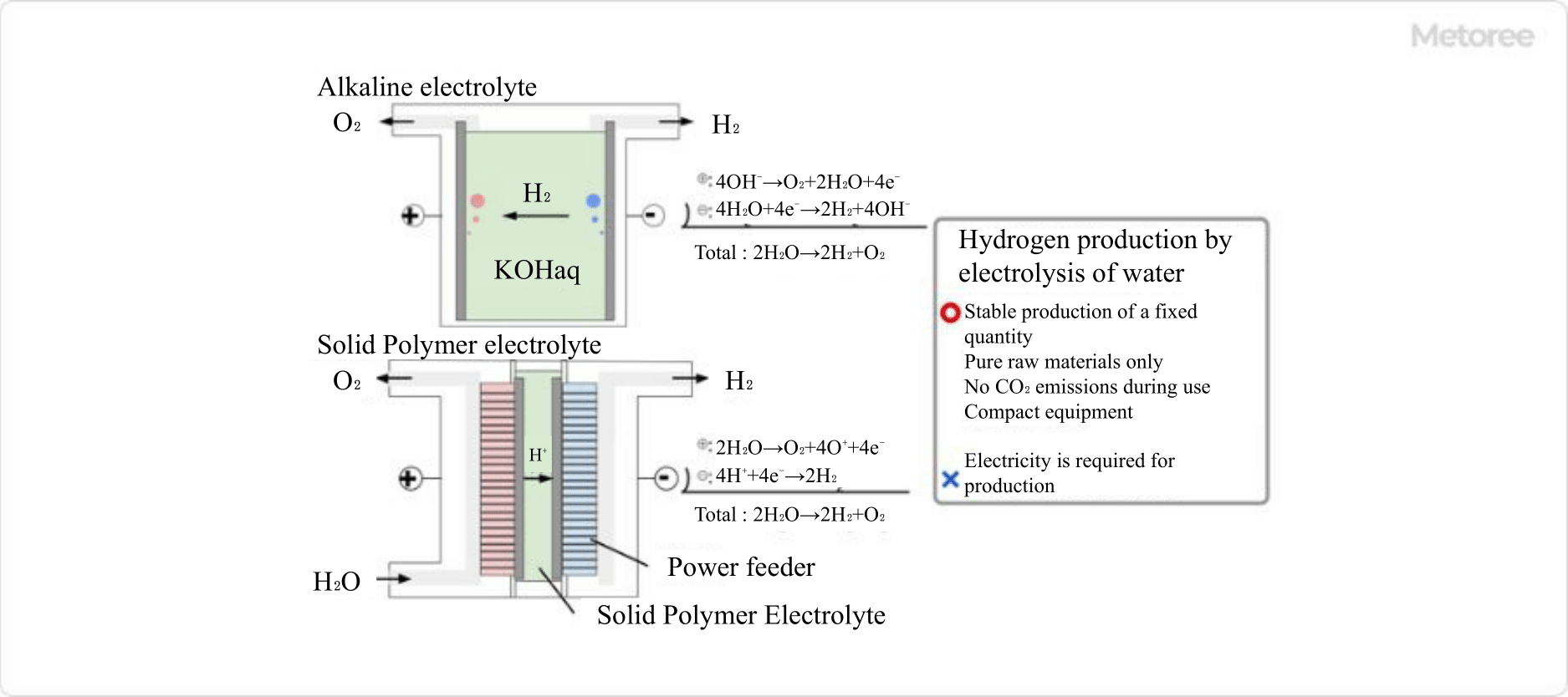

Figure 1. Production of hydrogen gas by electrolysis of water

Hydrogen and oxygen can be extracted through the electrolysis of water. While pure water has low efficiency in this process, it can be improved using electrolytes such as potassium hydroxide, solid polymer electrolytes, or ion-exchange membranes. Some hydrogen gas generators incorporate a purification system with a catalyst like palladium to enhance the purity of the produced hydrogen gas.

Electrolysis of water is suitable for producing hydrogen gas in small quantities and is ideal for research purposes and indoor use.

2. Steam Reforming

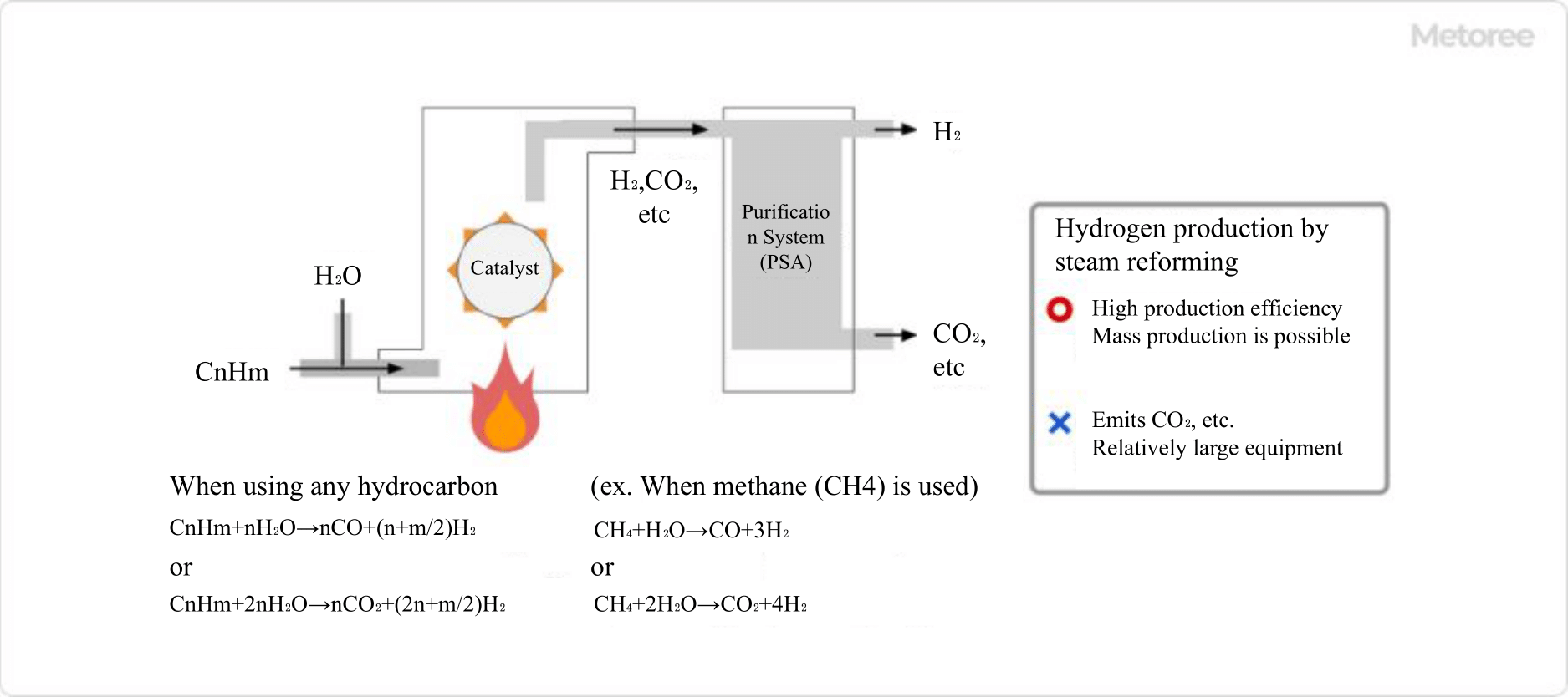

Figure 2. Production of hydrogen gas by steam reforming

Steam reforming involves the high-temperature steam reaction with hydrocarbons or coal in the presence of a catalyst, resulting in the generation of hydrogen gas. Carbon in the hydrocarbons combines with oxygen in the water to form carbon monoxide, effectively separating molecular hydrogen from both the hydrocarbons and water. The hydrogen produced via steam reforming often requires purification using methods like pressure fluctuation adsorption (PSA) due to impurities.

Steam reforming is commonly used in industrial applications to efficiently produce large volumes of hydrogen gas.

While there are various methods for hydrogen gas generation, the above two methods are the most prevalent.

Additional Information on Hydrogen Gas Generators

1. Advantages of Hydrogen Gas Generators Compared to Gas Cylinders

Hydrogen gas generators offer two key advantages compared to gas cylinders: reduced risk of gas leakage and elimination of the need for cylinder replacements.

Reduced Risk of Gas Leakage

Hydrogen gas is flammable and poses an explosion risk when mixed with oxygen. The risk of explosion is lower outdoors or in well-ventilated spaces due to hydrogen's light and diffusive nature. However, in small, poorly ventilated areas, gas leakage from cylinders can lead to an increased risk of explosion if the hydrogen content in the air exceeds 4 vol%. There is also a potential for indoor asphyxiation.

Hydrogen gas generators can produce only the required amount of hydrogen gas, and excess gas is safely exhausted, significantly reducing the aforementioned risks. They are considered relatively safe for indoor use.

No Need for Cylinder Replacements

Once installed, hydrogen gas generators do not require cylinder replacements. This eliminates the need to transport and replace gas cylinders, reducing labor costs and carbon dioxide emissions.

2. Renewable Potential in Hydrogen Production

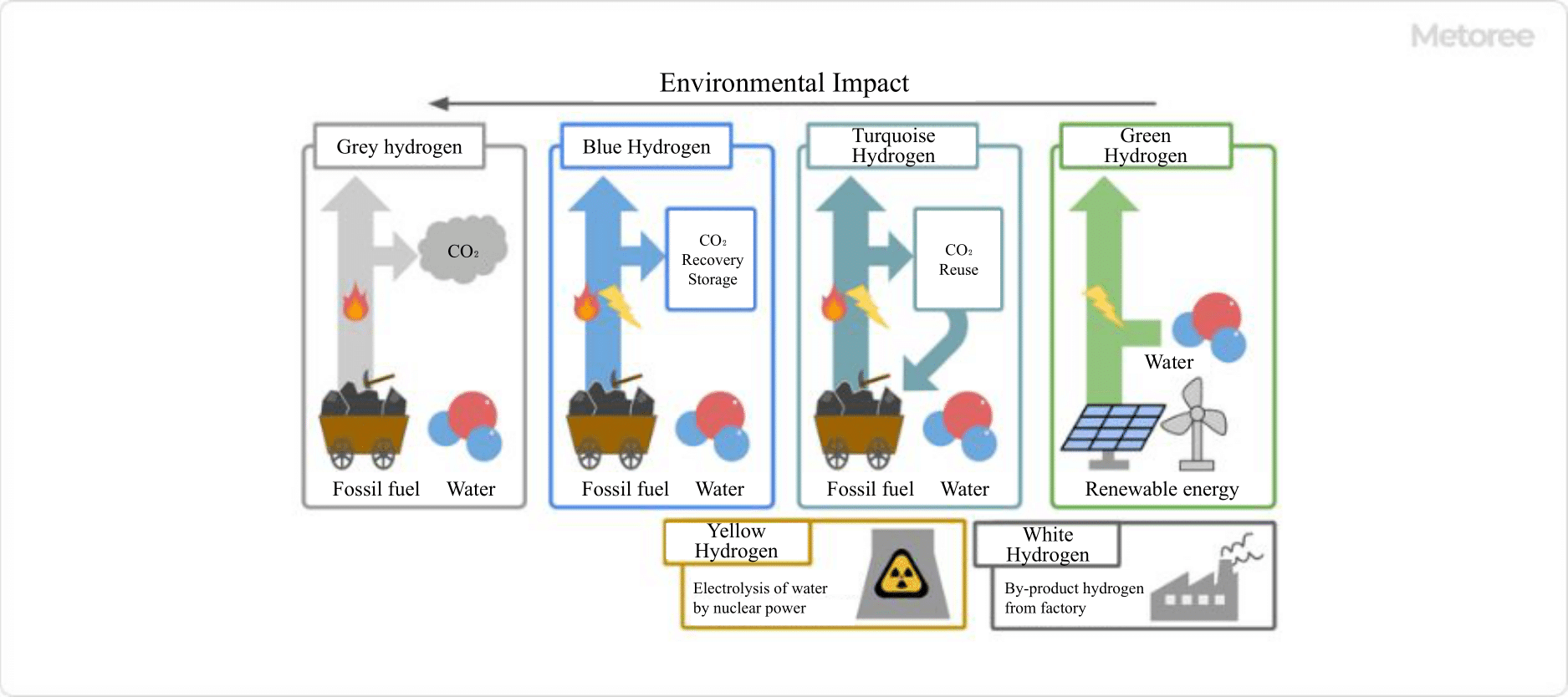

Figure 3. Color coding of hydrogen according to production method

Hydrogen is gaining attention as a clean energy source since its use results in the emission of only water, without carbon dioxide or other harmful substances.

However, in current scenarios, carbon dioxide and other emissions are associated with hydrogen gas production and transportation. To achieve truly clean energy use, the sum of carbon dioxide emissions from raw material acquisition to production and consumption must be reduced to less than zero. Hydrogen produced under these conditions is referred to as green hydrogen and is considered a completely clean energy source.

By generating hydrogen gas on-site, the need for transportation from production to consumption can be eliminated. Achieving green hydrogen production entails reducing carbon dioxide emissions to zero during hydrogen gas production. This can be achieved by using electricity from renewable sources like solar and wind power for electrolysis. Steam reforming with biomass is another method for producing green hydrogen, though it is less suitable for large-scale production due to raw material collection costs.

While still in the research phase, methods such as water and methane pyrolysis and artificial photosynthesis are being explored for green hydrogen production.

List of 11 Hydrogen Gas Generator Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- Canada

- Switzerland

- United Kingdom

-

-

-

PerkinElmer Inc.

PerkinElmer and other generators

Manufacturer Overview

PerkinElmer Inc., founded in 1937, is an American manufacturer headquartered in Waltham, Massachusetts, specializing in laboratory technology and management. The company's product offerings include analysis and characterization instruments, software, and consumables. Such offerings cover chromatography, mass spectrometry, molecular and atomic spectroscopy. They also provide immunoassay and food quality analyzers, as well as the simultaneous thermal analyzer (STA). These products find applications in various industries, such as biopharmaceuticals, food safety, lithium battery, and water resource management. PerkinElmer also offers OneSource Laboratory Services, providing knowledge, application, and service solutions for scientific laboratories. Additionally, their LABStartUp program supports new laboratories with instrumentation, consumables, and funding.

-

-

-

-

-

CP Lab Safety

Hydrogen Gas Generator

Company Overview

California Pacific (CP) Lab Safety is an American manufacturer and distributor of laboratory safety solutions founded in Novato, California in 1996. The company produces both lab and environmental safety equipment and devices, including waste containers, safety vents, biodegradable bags, and personal protective equipment (PPE). They also offer custom design and engineering services for customer projects, as well as technical support and quality assurance. CP Lab Safety serves California’s government agencies, departments and offices, as well as clients in its research, education, and healthcare institutio.

-

-

-

-

-

Chrom Tech, Inc

HYDROGEN GENERATORS

Company Overview

Chromtech is a company that specializes in the distribution of chromatography products, laboratory supplies, and scientific equipment. They offer a wide range of products including gas chromatography systems, liquid chromatography systems, columns, sample preparation products, and more. Chromtech aims to provide their customers with high-quality products, exceptional service, and technical support to help them achieve their goals. Their website provides customers with detailed information on their products and services, and offers easy online ordering.

-

-

-

-

-

LNI Swissgas

Hydrogen Gas Generators

Manufacturer Overview

LNI Swissgas, established in 1974 in Switzerland, is a manufacturer and supplier of high-precision gas generators and calibration systems. The company specializes in solutions for gas generation and analysis, catering to industries such as environmental monitoring, industrial processes, and laboratories. Devoted to providing gas solutions, LNI Swissgas offers a diverse range of gas generators, calibration standards, and analyzers. This ensures precise gas control for critical processes in laboratories, research institutions, and industrial facilities. LNI Swissgas's devotion to technological excellence is evident in their cutting-edge products, positioning them as a dependable provider of advanced gas solutions.

-

-

-

-

-

Peak Scientific Instruments.

hydrogen generator

Manufacturer Overview

Peak Scientific Instruments, founded in Glasgow, UK, in 1997 is a manufacturer of gas generators for analytical laboratories. The company's product portfolio includes nitrogen generators, hydrogen generators used for flame gas in FID detectors and carrier gas in GC instruments, and zero air generators. Their products are used in industries such as Food and Beverage, Pharmaceutical and Biotechnology, Chemical and Petrochemical, Environmental Testing and healthcare. The company provides services such as Product Selection Guidance, Engineering Support, and Custom Manufacturing.

-

-

-

-

-

SUMITOMO SEIKA CHEMICALS CO.,LTD.

Hydrogen Gas Generator

Manufacturer Overview

Sumitomo Seika Chemicals Co. LTD., founded in 1944 and headquartered in Osaka, Japan, is a manufacturer of functional chemicals, water-absorbing resins, and specialty gases. Some of its products include Aqua Keep, a super-absorbent resin produced using polymerization technology, and Aqua Coke, a nonionic polyalkylene oxide-based resin with water-absorbent properties. These resins find applications in various areas, such as in disposable diapers and as coagulants for wastewater treatment. The company was initially established for the production and sale of fertilizer. However, in 1981, it embarked on an expansion into functional resins, chemicals, and electronic gas businesses.

-

-

-

-

-

Better Fuel Technology

SuperKit hydrogen generator

Company Overview

Better Fuel Technology is a manufacturer and supplier of fuel-saving equipment such as hydrogen generators and engine controllers established in 2006 and headquartered in Ottawa, Ontario, Canada. The company’s hydrogen generator product portfolio includes CarKit which is used for vehicles with an engine size of 0-4.0 liters, SuperKit for vehicles with a 4.1-8.0liters engine, TruckKit for 8.1-12.0-sized engines, and ProKit for 12.1-16.0-sized engines. It also offers reservoirs intended for a 1-3 liter and 3-16 engine capacity. The company also offers the ProTuner, a universal fuel reduction system compatible with all engines.

-

-

-

-

-

SilPac

Hydrogen Generators

Company Overview

SilPac, founded in 2000, is a manufacturer and distributor of gas handling solutions headquartered in California, USA. The company specializes in high-purity gas delivery systems and industrial gas handling solutions. The company manufactures gas delivery systems, pressure regulators, and hydrogen generators. With various types of gas delivery systems, the company can handle multiple gases, including toxic, corrosive, flammable, and inert gases. These systems safely reduce gas pressure from cylinders and can handle different gas volumes. Additionally, the company manufactures purifier panels, bypass systems, and gas purifiers.

-

-

-

-

-

Air Products

Hydrogen Onsite Generators

Company Overview

Air Products and Chemicals, Inc. was established in 1940 and is based in Allentown, Pennsylvania as a manufacturer and distributor of atmospheric gases. Their product range comprises natural gas liquefaction (LNG) technology and equipment, liquid fuel, epoxy additives, advanced coatings, and adhesives, used in various industrial gas projects, including gasification initiatives that sustainably transform natural resources into syngas for the creation of valuable electricity, fuels, and chemicals. Its applications consist of effluent aeration, atmosphere control, atomic absorption, spectroscopy, annealing, and catalyst regeneration. The Company operates in various industries such as automotive, aerospace, chemicals, and healthcare.

-

-

-

-

-

Solar Impulse Foundation

Dyomix Oxy-Hydrogen Mobile gas generator

Company Overview

Solar Impulse Foundation, headquartered in Lausanne, Switzerland, is a pioneering organization devoted to advancing clean and sustainable technologies. Established in 2016, the foundation is a driving force behind groundbreaking solutions that address environmental challenges and promote energy efficiency. The Solar Impulse Foundation works on identifying and promoting cutting-edge clean technologies through its "Solar Impulse Efficient Solution" label. This label recognizes and supports products, services, and processes that have a positive impact on the environment and add to a more sustainable future.

-

-

-

-

-

PARKER HANNIFIN JAPAN LTD

Hydrogen Gas Generators

-

-

Hydrogen Gas Generator Manufacturer Ranking

*Including some distributors, etc.Ranking as of April 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | PerkinElmer Inc. |

20.0%

|

| 2 | CP Lab Safety |

15.8%

|

| 3 | LNI Swissgas |

14.2%

|

| 4 | Chrom Tech, Inc |

6.7%

|

| 5 | Better Fuel Technology |

6.7%

|

| 6 | Solar Impulse Foundation |

6.7%

|

| 7 | Peak Scientific Instruments. |

6.7%

|

| 8 | PARKER HANNIFIN JAPAN LTD |

6.7%

|

| 9 | Air Products |

5.8%

|

| 10 | SUMITOMO SEIKA CHEMICALS CO.,LTD. |

5.8%

|

Derivation Method

The ranking is calculated based on the click share within the hydrogen gas generator page as of April 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- PerkinElmer Inc.: 14,000

- SUMITOMO SEIKA CHEMICALS CO.,LTD.: 1,384

Newly Established Company

- CP Lab Safety: 1996 (28 years ago)

- Peak Scientific Instruments.: 1992 (32 years ago)

- SUMITOMO SEIKA CHEMICALS CO.,LTD.: 1944 (80 years ago)

Company with a History

- Air Products: 1940 (84 years ago)

- SUMITOMO SEIKA CHEMICALS CO.,LTD.: 1944 (80 years ago)

- Peak Scientific Instruments.: 1992 (32 years ago)

Hydrogen Gas Generator Manufacturers in United States

*Including some distributors, etc.

Global Distribution of Hydrogen Gas Generator Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

3 | 42.9% |

Switzerland

Switzerland

|

2 | 28.6% |

United Kingdom

United Kingdom

|

1 | 14.3% |

Canada

Canada

|

1 | 14.3% |

List of Hydrogen Gas Generator Products

7 products are listed.

Kansai Autome Equipment

Hydrogen gas generator KAHG2 type standard hydrogen gas generator

10+ people viewing

Last viewed: 5 hours ago

You can easily generate hydrogen and oxygen simply by supplying pure water and electricity. By supplying electricity obtained from natural energy ...

SUMITOMO SEIKA CHEMICALS CO.,LTD.

Using an excellent adsorption capacity PSA hydrogen gas refining device

H2-PSA, which is decomposing city gas and methanol and manufactures hydrogen gas, is in operation. In addition, you can collect and purify high -pu...