27 Articulated Robot Manufacturers in 2024

This section provides an overview for articulated robots as well as their applications and principles. Also, please take a look at the list of 27 articulated robot manufacturers and their company rankings. Here are the top-ranked articulated robot companies as of April, 2024: 1.Robotic Automation Systems, 2.Delta Electronics, Inc., 3.Mitsubishi Electric Automation, Inc.

Table of Contents

What Is an Articulated Robot?

An articulated robot is a robot with multiple joints in their arms.

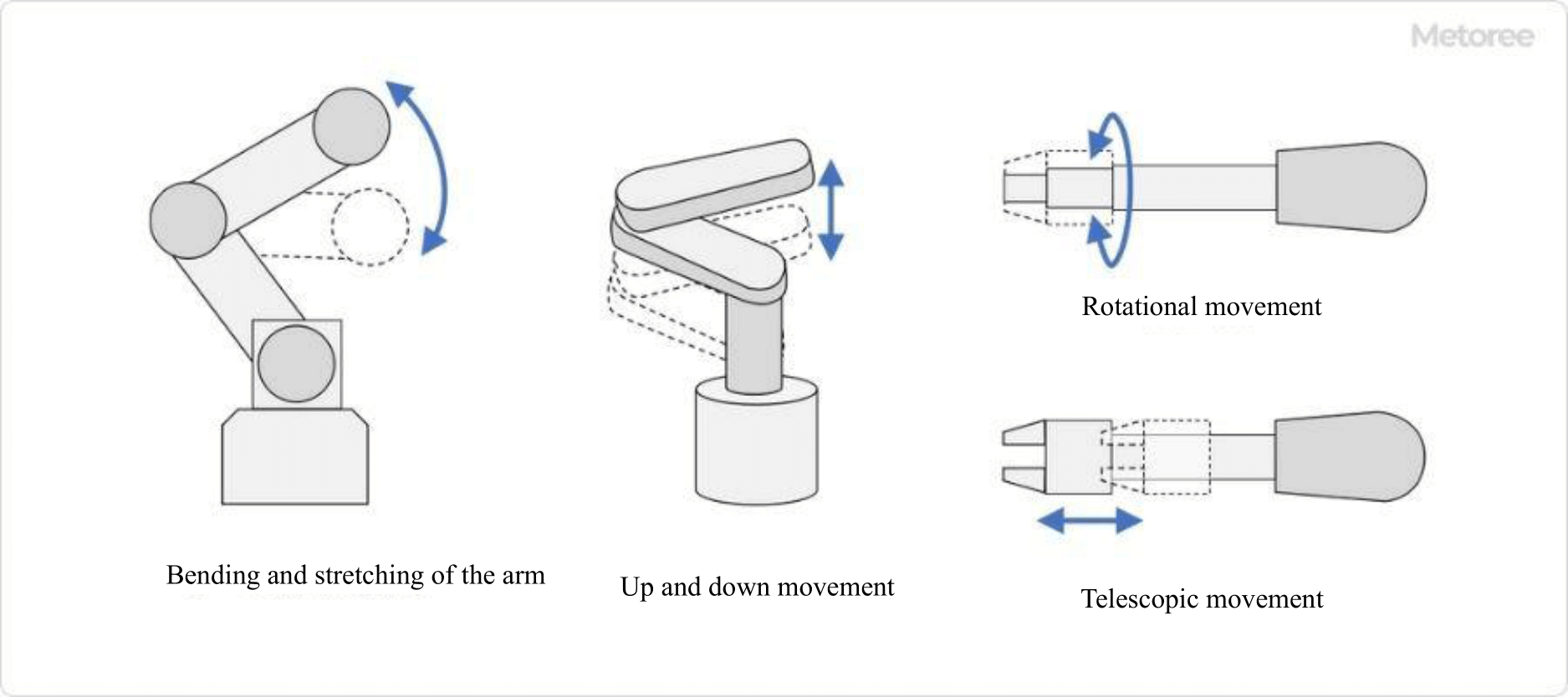

The joints perform the following actions:

- Bending and stretching of the arm

- Vertical movement

- Rotation

- Extension and contraction

Articulated robots have joints that resemble human movements, such as bending and stretching, as well as linear joints unique to articulated robots, such as extension and contraction. This enables them to perform various tasks in place of humans.

Figure 1. Joint movement of articulated robots

The main types of articulated robots are vertically articulated robots and horizontally articulated robots. Each has a different arm and joint structure, and each specializes in different tasks.

Uses of Articulated Robots

Articulated robots are mainly used to perform the following tasks in place of humans:

- Heavy-duty work such as lifting heavy loads

- Work that requires repetition of the same task for a long period of time

- Work that requires skilled workmanship

- Inspection work using sensors and cameras

Unlike humans, robots do not get tired and can accurately perform the same task for a long time. Leaving simple tasks to robots allows humans to engage in value-added processes, thereby increasing factory productivity.

In addition, the robot's ability to reproduce precise movements allows it to accurately trace the movements of skilled workers. This is expected to preserve skill level by transferring the skills of veteran technicians who are about to retire to the robot. With the recent development of AI technology, sensors and cameras can be attached to articulated robots to automate inspections.

Principles of Articulated Robots

Links and joints in a robot correspond to human bones and joints, respectively. The joints are rotational axes and linear motion mechanisms that increase the range of motion of the links, allowing the robot to perform tasks similar to those performed by humans.

Early robots were driven by hydraulic power, but today, motor-driven robots are the norm. Electronic control enables more precise movements.

Other Information on Articulated Robots

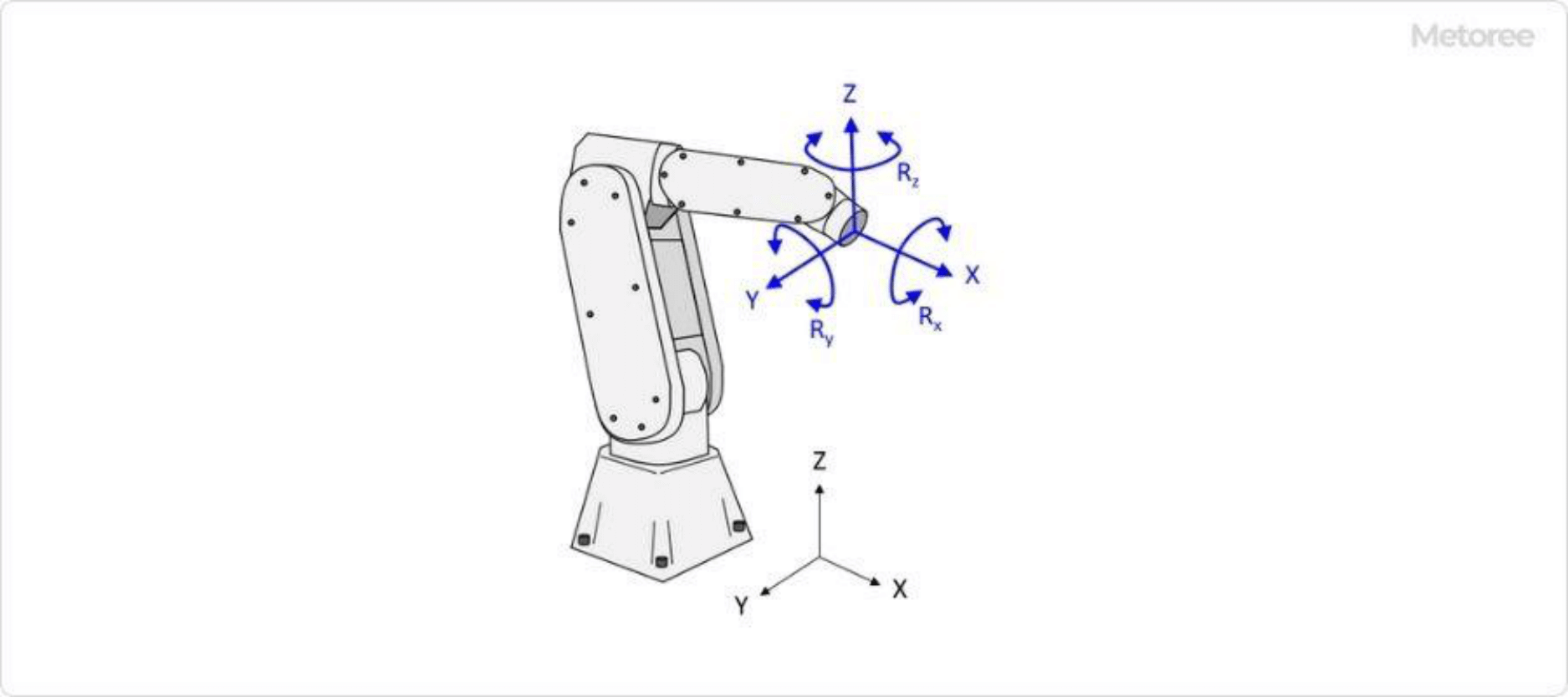

1. What Are Vertically Articulated Robots?

Vertically articulated robots are robots whose joints are oriented to move the arm vertically. Vertically articulated robots generally have six axes and can perform horizontal and vertical movements such as X, Y, and Z, as well as rotational movements such as Rx, Ry, and Rz.

Vertically articulated robots are capable of movements similar to those of the human arm.

- Work that requires an oblique approach, such as welding, painting, etc.

- Workpiece transfer work in locations with complex entry paths

and other tasks that require a diagonal approach, such as welding and painting.

Figure 2. Vertical articulated robot

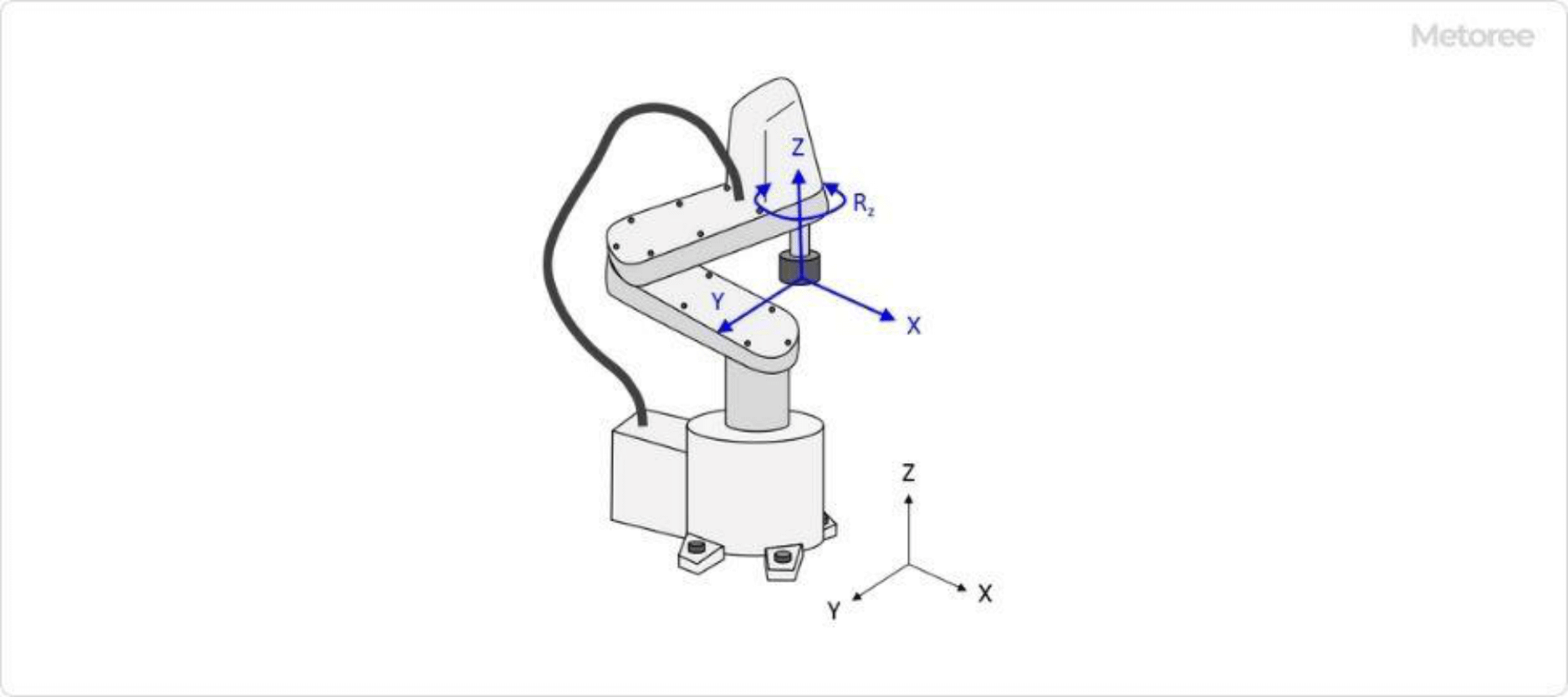

2. What Are Horizontally Articulated Robots?

Horizontally articulated robots are equipped with three rotational axes that operate mainly in the horizontal direction. They are often referred to as SCARA robots. In addition to the horizontal rotational axes, products with one additional axis for vertical motion are common.

Horizontally articulated robots have the following advantages over vertically articulated robots

- Quick movement in the plane (X, Y, and Rz directions)

- Higher rigidity in the vertical direction

- Low cost

The following are some of the tasks that take advantage of the benefits of Horizontally Articulated Robots.

- Picking workpieces from a conveyor belt and packing them into boxes

- Vertical screw tightening work

- Aligning workpieces in a plane

Horizontally articulated robots and horizontally articulated robots are the same type of articulated robot but have different characteristics, so they should be used according to the work you want to perform.

Figure 3. Horizontally articulated robot

3. Low-Cost Articulated Robots

Articulated robots are expensive, traditionally costing tens of thousands of dollars and more, but in recent years, low-cost articulated robots have become available from a variety of manufacturers. These robots are mainly used for electronic construction and programming learning.

Inexpensive robots can be purchased for as little as several hundred dollars, but because they use inexpensive joint structures and motors, their positioning accuracy, repetitive stop position accuracy, operating speed, and durability are much lower. When purchasing a robot, it is necessary to carefully judge whether or not it can withstand practical use.

List of 27 Articulated Robot Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- China

- Germany

- Italy

- Japan

- Slovenia

- Switzerland

- Taiwan

- United Kingdom

-

-

-

Mitsubishi Electric Automation, Inc

Industrial Robot

Manufacturer Overview

Mitsubishi Electric Automation, Inc., established in 1921 and headquartered in Tokyo, Japan, is a manufacturer of factory automation products, including programmable controllers and laser processing machines. The company's product portfolio spans multiple industries, with solutions tailored for automotive equipment, building systems, semiconductors and devices, visual information systems, transportation systems, and more. These solutions are applicable in various sectors such as machine tooling, oil and gas, packaging automation, power and water, printing, and converting. Its clientele includes companies such as Hamrick Packaging Systems, Miller Process Coating, Full House Machinery, Air Clear, and Millennium Packaging.

-

-

-

-

-

Robotic Automation Systems

Articulated Robots

Manufacturer Overview

Robotic Automation Systems is a provider of turnkey robotic automation systems for horizontal and vertical plastic injection molding. It is headquartered in Waunakee, Wisconsin, and was established in 1994. RAS specializes in robotic automation services, from entry-level to complex automation solutions. Its robotic automation products include robots, grippers, and vision systems. For customization, the company goes through the design, engineering, build, full system integration, custom programming / HMI, installation, and training process. RAS's customers include plastic injection molders, blow molders, and thermoformers. The company’s customers include plastics manufacturers in multiple industries, including automotive, medical, and packaging.

-

-

-

-

-

KASTO Maschinenbau GmbH & Co. KG

Material handling

Manufacturer Overview

KASTO Maschinenbau GmbH & Co. KG is a manufacturer of metalworking machine tools. It is headquartered in Achern, Germany since 1910. The company designs, manufactures, and supplies multiple metalworking machine tools. Its products categories include Sawing machines such as Hack saws, Bandsaws, Circular saws and Testimonials saws and Storage Systems such as Bar storage, Sheet metal storage, and Testimonials storage as well as horizontal lathes, vertical lathes, and CNC machining centers. Its products are used in many industries, including automotive, aerospace, and shipbuilding. The company also offers technical support, installation, and training services to ensure efficient utilization of its products.

-

-

-

-

-

S.I.P.A. S.p.A

Robotic handling systems

Manufacturer Overview

S.I.P.A. S.p.A., founded in 1980 and headquartered in Vittorio Veneto, Italy, is a manufacturer of solutions for plastic packaging production and is part of the Zoppas Industries Group of companies. Its product portfolio includes bottle production systems, preform systems, and molds, and it also sells secondary packaging solutions like palletizers and robotic handling systems. The company is responsible for developing over 3000 new containers yearly and can deliver programs for new molds or mold conversions from single to 200 cavities. It is ISO 9001 and ISO 14001 certified and offers injection mold refurbishing and conversion services.

-

-

-

-

-

RNA Automation Limited

Robotic Systems

Manufacturer Overview

RNA Automation Limited is a manufacturer specialized in automation engineering formed in 1972 with a previous heritage tracing to 1898 in Aachen, Germany. The company makes products in feeding and handling robotics, like bowl and centrifugal feeders, as well as VariFeed and VariPic™. It also works on bespoke automation, offering special purpose machinery, robotic systems and vision inspection systems, for instance. It also includes a detailed archive of downloadable product catalogs, information and instructions. The firm has carried out successful projects in various industries, such as life sciences, consumer goods, automotive, food and beverages, plastics and electronics.

-

-

-

-

-

Skilled Group

Articulated Robots

Manufacturer Overview

Skilled Group was established in 1973 in Schio, Italy, and is a manufacturer of industrial automation products. The company's products include conveyors, robot palletizers and automated guided vehicles that are used in food, beverage, consumer goods and pharmaceutical industries for automation. It also offers certified training to customers on how to use the products. The company has other offices in the USA and Europe. It is ISO 9001 certified and has other accreditations from different countries, like CSA in Canada and UL in Germany.

-

-

-

-

-

FANUC

Paint Robot

Manufacturer Overview

FANUC Corporation, established in 1972 and headquartered in Yamanashi Prefecture, Japan, is a manufacturer of factory automation, robomachine, IoT, and robotics. The company offers an extensive and diversified product portfolio including, servomotor, robodrill small cutting machine, roboshot electric injection molding machine, robocut wire electrical discharge machine, and lasers. These cutting-edge products cater to a wide range of industries, spanning from automotive, health care, and aerospace to electronics. The aim of the company is to provide efficient and low-cost products to customers.

-

-

-

-

-

Shibaura Machine

Vertical Articulated Robots

Manufacturer Overview

Initially established in 1938, Shibaura Machine has three-quarters of a century providing Comprehensive technology and supporting the “monozukuri” of the world. With the technical and development capabilities of the Shibaura Machine Group, various machines and services create rich value and contribute to the creation of an industrial base. Working on the eight technical platforms, they develop and manufacture a wide range of production devices that meet the needs of the times, delivering the best solutions by combining our accumulated excellent know-how and the latest technology. Shibaura Machine uses its knowledge of modern global standards of advanced technology to support Japan and the world.

-

-

-

-

-

Stäubli International AG.

industrial robots

Manufacturer Overview

Stäubli began in Horgen, Switzerland in 1892. Stäubli designs, produces, distributes, and provides support for products for numerous industries including aerospace, alternative fuels, medical devices, packaging, photovoltaics, and semiconductors. Stäubli has 4 primary product lines including electrical connectors, fluid connectors, robotics, and textile. Electrical connector products include cable couplers, modular connectors, and test and measurement connectors. Fluid connectors include mold clamping systems, quick and dry disconnect couplings, and safety breakaway couplings. Robotics include industrial robots, collaborative robots, and mobile robots. Textile includes weaving preparation and frame weaving.

-

-

-

-

-

Shenzhen Han's Robot Co., Ltd

Collaborative Robot

Manufacturer Overview

Shenzhen Han's Robot Co., Ltd, a subsidiary of Han's Laser Technology Industry Group Co., Ltd., is a Chinese manufacturer of intelligent robots based in Shenzhen and Foshan and established in 2017, Industrial collaborative robots are among the company’s products designed to work alongside humans in shared workspaces. Han's Robot also offers the HR series of multi-sensor automated guided vehicles (AGV) for indoor item transportation. Furthermore, the company develops the STAR mobile manipulator with human-like functional capabilities such as material detection and product handling. The company’s products cater to various industries, including the automotive, healthcare, and semiconductor sectors.

-

-

-

-

-

UNITED PROARC CORPORATION

Weld robot system

Manufacturer Overview

United ProArc Corporation is a CNC cutting and drilling machines manufacturer established in 1966 in Pingjen, Taoyuan, Taiwan. The company's products include CNC drilling machines designed for steel beams or plates and CNC cutting machines capable of cutting through metal materials using laser or oxy-fuel technologies. It also offers welding automation equipment that employs metal inert gas (MIG) and metal active gas (MAG), flux-cored arc welding (FCAW), and tungsten inert gas (TIG) welding processes. These products find application in sectors such as industrial manufacturing, steel processing, and bridge construction.

-

-

-

-

-

Omron

Articulated Robots

Manufacturer Overview

Omron Corporation, started in 1933 and headquartered in Kyoto, Japan, is a manufacturer of automation components, equipment, and systems, and it developed the first contactless proximity switch in 1960. It has four domains, including industrial automation, electronic components, healthcare, and social systems, and it provides products and services in around 120 countries and regions. Some of its products include microsensing devices, access control systems, industrial robots, surveillance cameras, and blood pressure monitors. In 1971, it developed the first online cash machine, and in 1972, it established Japan’s first welfare factory.

-

-

-

-

-

KUKA AG

Industrial robots

Manufacturer Overview

KUKA AG was founded in 1898 in Augsburg, Germany. The company is a subsidiary of GD Midea Holding Co., Ltd. and is an automation developer, designing and manufacturing robot-based automation solutions for medical, automotive, warehousing, and distribution industries. The company’s product segments include robot systems, production machines, and systems, mobility as a driver of Industry 4.0, and process technologies that provide special welding processes to factories. The company’s services include repair and servicing for robots and machines and engineering services for designing and programming robotic systems.

-

-

-

-

-

Kollmorgen Corporation

Industrial Articulated Robots

Manufacturer Overview

Founded in New York in 1916, Kollmorgen designs and manufactures motion system, drives, motors, actuators, gear heads, automated guided vehicle (AVG) systems, and accessories across a number of implementations and industries. These include aerospace, AGV, food&beverage, machine tools, metal forming, medical automation and imaging, energy, packaging, pharmaceutical, postal sorting, printing, robotics, smart warehouses, and tire and rubber production. Kollmorgen assists customers both in custom designs and in allowing customers to design their own devices based on individual needs.

-

-

-

-

-

GWEIKE

FANUC Robot Arms

Company Overview

GWEIKE, launched in 2004 in Kielce, Poland, is a manufacturer and supplier of laser machines for Africa, Asia, South East Asia, Australia and Canada. The company manufactures fiber cutting, laser welding, CO2 laser cutting, and laser marking machines that are certified by European Union CE, American DA, and ISO 9001. It also provides machine maintenance, original spare parts supply, and technical training services. The company has organized exhibitions like G.Weike in Emo Hannover and the G.Weike World Exhibition Tour.

-

-

-

-

-

WINKEL GmbH

WINKEL RLE robot tracks

Company Overview

WINKEL GmbH was founded in 1981 and is located in Illingen, Baden-Württemberg, Germany is a manufacturer and supplier of heavy load linear systems. The company offers an array of product portfolios, including telescopic tables with telescopic forks, precision angle rollers axial rollers adjustable via eccentric, and PUMA pallet stacker cranes among others. Additionally, it extends services like product inquiries, quality management, and product registration. These precision products cater to diverse applications in material handling, aerospace engineering, and factory automation.

-

-

-

-

-

HIRATA Corporation

Articulated robots

Company Overview

Hirata Corporation is a manufacturer and distributor of industrial robotic and logistics equipment based in Kumamoto, Japan. Established in 1951, the company first dabbled in manufacturing and marketing industrial vehicles. In 1958, they turned to manufacturing agricultural-related products. By 1959, they started their first conveyor belt line, and in May 1964, their television assembly line was launched. In 1977, they developed their first robot-controlled machine, and from there, they shifted towards robotic logistical equipment. The company is present in eight countries, namely Japan, Taiwan, the United States, Mexico, China, Singapore, Malaysia, and Thailand.

-

-

-

-

-

KHS Group

Innopal RK articulated robot

Company Overview

KHS Group, founded in 1868 and based in Dortmund, Nordrhein-Westfalen, Germany, is a manufacturer and supplier of filling and packaging equipment. The company's product offerings include Machines and equipment, Turnkey Solutions, Packaging Solutions, Highly Efficient Single-Machine Solutions, and Consulting Expertise. These products are designed for efficient filling and packaging operations across various sectors. It primarily serves the beverage, food, and non-food industries. Additionally, The company offers services such as on-site support, parts & materials supply, consulting, and digital services.

-

-

-

-

-

DENSO

Articulated Robot

Company Overview

DENSO is a global manufacturer and supplier of advanced robotics technology, automotive components, industrial products and home appliances. The company was founded in 1949 and headquartered in Tokyo, Japan. The company’s operations are carried out through the following business units: Automotive, Consumer Products, Industrial Products and New Business Fields. The Automotive unit delivers a wide variety of automotive products and technologies that minimize environmental impact and traffic accidents while also increasing comfort and convenience. The New Business Fields unit engages in the business of solving problems and benefiting society beyond the automotive industry.

-

-

-

-

-

-

-

-

-

-

-

-

-

Delta Electronics, Inc.

Articulated Robot

Company Overview

Delta Electronics was founded in 1971 in Taipei, Taiwan. Delta Electronics is a global provider of power and thermal management solutions, serving power electronics, automation, and infrastructure. Delta’s power electronics division sells components such as inductors, power and system components such as industrial power supplies and external adapters, fans and thermal management such as DC brushless fans and motors, and automotive electronics. Automation includes industrial automation and building automation subdivisions. Infrastructure includes ICT infrastructure, energy infrastructure & industrial solutions, and display & visualization. Delta Electronics also provides solutions for data center, telecom energy, and EV charging.

-

-

-

-

-

Sinterpack Burgos

SOLUTIONS

-

-

-

-

-

TECHMAN ROBOT INC

Heavy Payload

-

-

-

-

-

Yaskawa America, Inc.

Articulated Robots

Company Overview

Yaskawa America Inc., started in 1967 and based in Waukegan, Illinois, is a manufacturer of machine controllers, industrial robots, and variable frequency drives and is part of Yaskawa Electric Corporation. Some of its products include industrial AC drives, machine controllers, and IEC programmable robots. The company incorporates the Kaizen method of continuous incremental improvements and Total Quality Management processes to prevent manufacturing defects, and its distributors must be certified and re-certified every two years. It is ISO 9001 certified and is the only industrial drives and motion control manufacturer to win the Deming Medal.

-

-

Articulated Robot Manufacturer Ranking

*Including some distributors, etc.Ranking as of April 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | KUKA AG |

13.6%

|

| 2 | Robotic Automation Systems |

10.6%

|

| 3 | Delta Electronics, Inc. |

9.1%

|

| 4 | Mitsubishi Electric Automation, Inc |

6.1%

|

| 5 | DENSO |

6.1%

|

| 6 | Shenzhen Han's Robot Co., Ltd |

6.1%

|

| 7 | HIRATA Corporation |

6.1%

|

| 8 | Kollmorgen Corporation |

6.1%

|

| 9 | Omron |

4.5%

|

| 10 | DENSO Robotics Incorporated |

3.0%

|

Derivation Method

The ranking is calculated based on the click share within the articulated robot page as of April 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- Shibaura Machine: 3,049

- KASTO Maschinenbau GmbH & Co. KG: 700

Newly Established Company

- Shenzhen Han's Robot Co., Ltd: 2017 (7 years ago)

- GWEIKE: 2004 (20 years ago)

- Plasmatreat GmbH: 1995 (29 years ago)

Company with a History

- Stäubli International AG.: 1892 (132 years ago)

- Shibaura Machine: 1949 (75 years ago)

- DENSO: 1949 (75 years ago)

Articulated Robot Manufacturers in United States

*Including some distributors, etc.

Global Distribution of Articulated Robot Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Germany

Germany

|

4 | 22.2% |

Italy

Italy

|

3 | 16.7% |

Japan

Japan

|

3 | 16.7% |

United States of America

United States of America

|

2 | 11.1% |

China

China

|

2 | 11.1% |

United Kingdom

United Kingdom

|

1 | 5.6% |

Switzerland

Switzerland

|

1 | 5.6% |

Slovenia

Slovenia

|

1 | 5.6% |

Taiwan

Taiwan

|

1 | 5.6% |