8 Glass Fuse Manufacturers in 2024

This section provides an overview for glass fuses as well as their applications and principles. Also, please take a look at the list of 8 glass fuse manufacturers and their company rankings. Here are the top-ranked glass fuse companies as of April, 2024: 1.Grote, 2.Pico of Canada Ltd, 3.SKS ELECTRONICS.

Table of Contents

Engaged in research on nitride semiconductor growth using the MBE method at Waseda University Graduate School. After graduating from graduate school in 2016, he joined a non-ferrous metal manufacturer.

Engaged in equipment maintenance and engineering work at metal smelting plants. Moved to a chemical manufacturer in 2022. Engaging in similar tasks.

What Is a Glass Fuse?

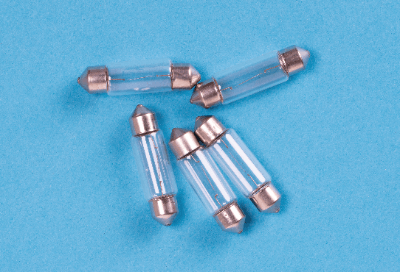

A glass fuse is a type of fuse that utilizes glass as a protective tube. They are the most common type of tube fuses. These fuses interrupt current flow by melting the element when an overrated current flows through them, preventing circuit breakage, smoking, ignition, and similar accidents.

Uses of Glass Fuses

Glass fuses are widely used in various applications:

- Control power supplies in motor control center units.

- Overcurrent protection for power lamps and instrument transformers.

- Protection for in-vehicle and motorcycle control units.

- On printed circuit boards of home appliances.

- On control boards of industrial rectifiers.

They are most often used in control circuits due to their compact and space-saving nature, operating faster than general breakers.

Principle of Glass Fuses

Glass fuses consist of a glass tube, an element, and a cap.

1. Glass Capillary

The glass capillary protects the filament. Most often made from PC glass, it allows for visual inspection to see if the filament has fused. Some glass fuses also contain an arc-quenching agent like silica sand to suppress arc generation when the filament breaks.

2. Elements

The element fuses in the event of overcurrent. Typically made from zinc, the thickness of the element corresponds to the allowable current and is visible from the glass tube. Other materials like lead, silver, or alloys are used to adjust the melting point.

3. Mouthpiece

The mouthpiece connects the fuse to the fuse holder. It's usually made of nickel-plated copper and contains printed information such as withstand voltage and allowable current.

Types of Glass Fuses

There are three main types of glass fuses:

1. Normal Fusing Type

Commonly used in telecommunications equipment, these fuses can withstand 200% of the rated current for about 2 minutes.

2. Time-Lag Blown Type

Time-lag fuses are designed to delay blowing and are used to protect motors and solenoid valves with large inrush or start-up currents.

3. Fast-Blow Type

Fast-blow fuses act almost instantaneously under excessive currents and are used to protect semiconductors from failure due to excessive or reverse currents.

Other Information on Glass Fuses

How to Use Glass Fuses

Glass fuses are inserted into fuse holders with mechanisms to hold them securely. Safety tools are used when replacing a fuse to avoid electric shock. The fuse's capacity should be greater than the rated current of the electrical component but less than the maximum capacity of the wiring or weakest component. The withstand voltage is also crucial, with variants available for 125 V and 250 V.

List of 8 Glass Fuse Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- China

- India

- Japan

-

-

-

SOC

Product Search

Manufacturer Overview

SOC fuse technology is a manufacturer company which has its headquarters in Japan which develops, manufactures and sell fuses for circuit protection of electronic equipment and electronics since 1958. The company has three subsidiaries in North America, Asia and Europe to carter their customers needs. SOC is being guided by its founding spirit of valuing its customers, shareholders and employees. The company is currently collaborating with automobile companies to develop fuses to protect the coming generation. The company is looking forward to come up with fuses with good capabilities.

-

-

-

-

-

SKS ELECTRONICS

Glass Fuse

Manufacturer Overview

SKS Electronic, established in 2018 and headquartered in Karnataka, India, is a manufacturer and supplier of electrical components. The company’s products include electrical resistors such as wire wound, metal oxide, and carbon film resistors. Its selection of electrical capacitors encompasses electrolytic, tantalum, and multilayer capacitors. It provides various electrical diodes, including standard recovery, power, and thyristor diodes. The company also offers electrical transistors, electronic relays, and AC/DC power modules. Each item is available in diverse sizes and specifications, catering to various industrial and commercial requirements.

-

-

-

-

-

Dongguan Tianrui Electronics Co., Ltd

Glass Fuse

Manufacturer Overview

Dongguan Tianrui Electronics Co., Ltd, established in 2010 and headquartered in Dongguan City, China, is a manufacturer and supplier of circuit protection components. The company's product portfolio includes automotive fuses, PCB electrical fuse holders, and negative temperature coefficient thermistors. These products find applications in various industries, including electronics manufacturing, industrial automation, and the automotive industry. The company is ISO 9001:2000 certified for its quality management system, with its main markets including the United States, the United Kingdom, and South Korea.

-

-

-

-

-

Grote

Glass Fuses

Manufacturer Overview

Grote, established in 1901, is a worldwide manufacturer and supplier of vehicle lighting and safety systems. The company’s manufactured products include white light, signal lighting, warning and hazard, fuse and circuit protection, and interior light, among others. Their products are used by heavy duty trucks and trailers, vocational and passenger vehicles, as well as vehicles used for agriculture, mining, construction, emergency and rescue, and military, among others. The company has been recognized as a preferred supplier to commercial vehicle manufacturers with world class systems to ensure the quality of its products.

-

-

-

-

-

-

-

-

-

-

-

Pico of Canada Ltd

GLASS FUSE ASSORTMENT

-

-

Glass Fuse Manufacturer Ranking

*Including some distributors, etc.Ranking as of April 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Grote |

25.8%

|

| 2 | Pico of Canada Ltd |

17.7%

|

| 3 | SKS ELECTRONICS |

16.1%

|

| 4 | Hallmark Electronics |

12.9%

|

| 5 | Dongguan TLC Electronic Technology Co.,Ltd |

11.3%

|

| 6 | SOC |

9.7%

|

| 7 | Shanghai Songshan Electronics Co., Ltd |

3.2%

|

| 8 | Dongguan Tianrui Electronics Co., Ltd |

3.2%

|

Derivation Method

The ranking is calculated based on the click share within the glass fuse page as of April 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

- SKS ELECTRONICS: 2018 (6 years ago)

- Dongguan TLC Electronic Technology Co.,Ltd: 2011 (13 years ago)

- Hallmark Electronics: 1982 (42 years ago)

Company with a History

- Grote: 1901 (123 years ago)

- Shanghai Songshan Electronics Co., Ltd: 1958 (66 years ago)

- Hallmark Electronics: 1982 (42 years ago)

Global Distribution of Glass Fuse Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

China

China

|

3 | 50.0% |

India

India

|

2 | 33.3% |

Japan

Japan

|

1 | 16.7% |