20 Small Truss Head Screw Manufacturers in 2024

This section provides an overview for small truss head screws as well as their applications and principles. Also, please take a look at the list of 20 small truss head screw manufacturers and their company rankings. Here are the top-ranked small truss head screw companies as of April, 2024: 1.Dongguan Yuhuang Electronic Technology Co., Ltd., 2.Shenzhen Shi Shi Tong Metal Products Co., Ltd., 3.Prince Fastener.

Table of Contents

1985-2014: Worked for Alstom Corporation, ABB Corporation, and Gadelius Corporation, designing Jungstrom air preheaters and mechanical design of diamond soot blowers. (ABB Corporation: https://new.abb.com/jp)

2014-2021: Worked as an engineering and project manager at Alvos Inc.

https://www.linkedin.com/in/yoichi-hiroki-92192394/

What Is a Small Truss Head Screw?

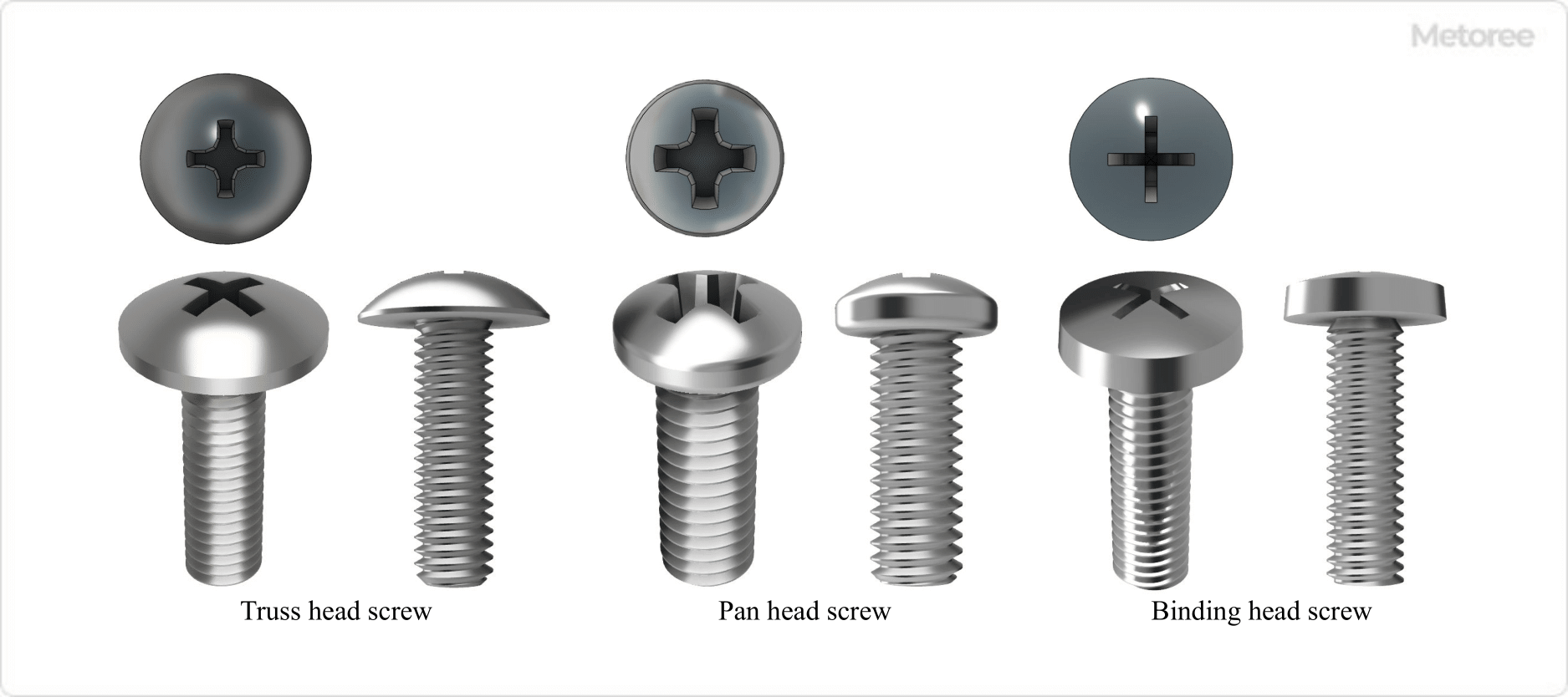

A small truss head screw features a flat screw head with a rounded top, offering a larger diameter than small pan head screws and a lower profile than small binding head screws. For visual reference, see Figure 1 depicting truss head screws alongside pan and binding head screws.

Figure 1. Truss Head Screw, Pan Head Screw, Binding Head Screw

Figure 1. Truss Head Screw, Pan Head Screw, Binding Head Screw

"Small screws" are defined as having a relatively small nominal diameter, typically with slotted or cross-shaped driving parts.

Uses of Small Truss Head Screws

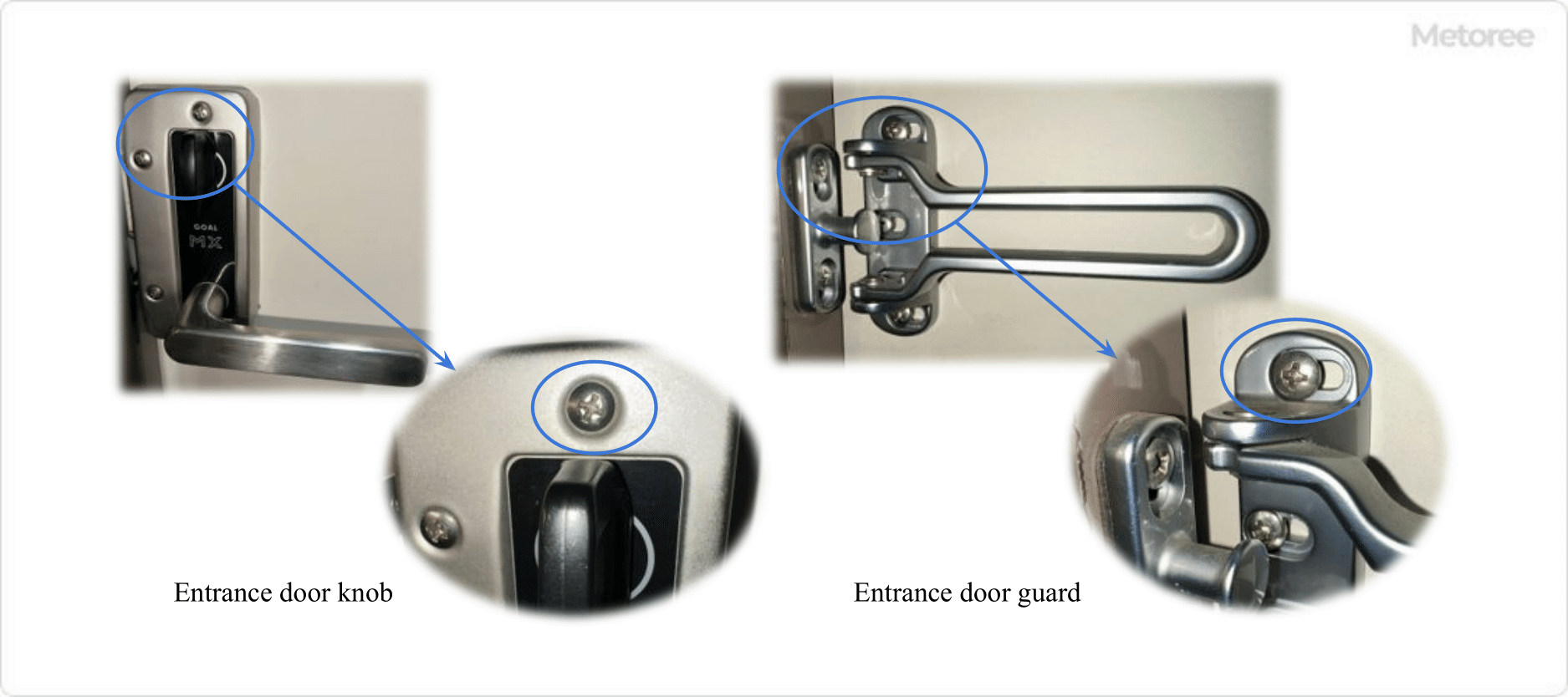

Small truss head screws are commonly used in applications where the female thread is directly created in the item being fastened, such as in door knob and guard installations, as illustrated in Figure 2.

Figure 2. Example of Using Truss Head Screws

Figure 2. Example of Using Truss Head Screws

These screws offer a large head diameter for increased contact area, enhancing resistance to loosening. The rounded head also contributes to aesthetics and prevents the seat surface from sinking into fastened parts, making them ideal for wooden components.

Principle of Small Truss Head Screws

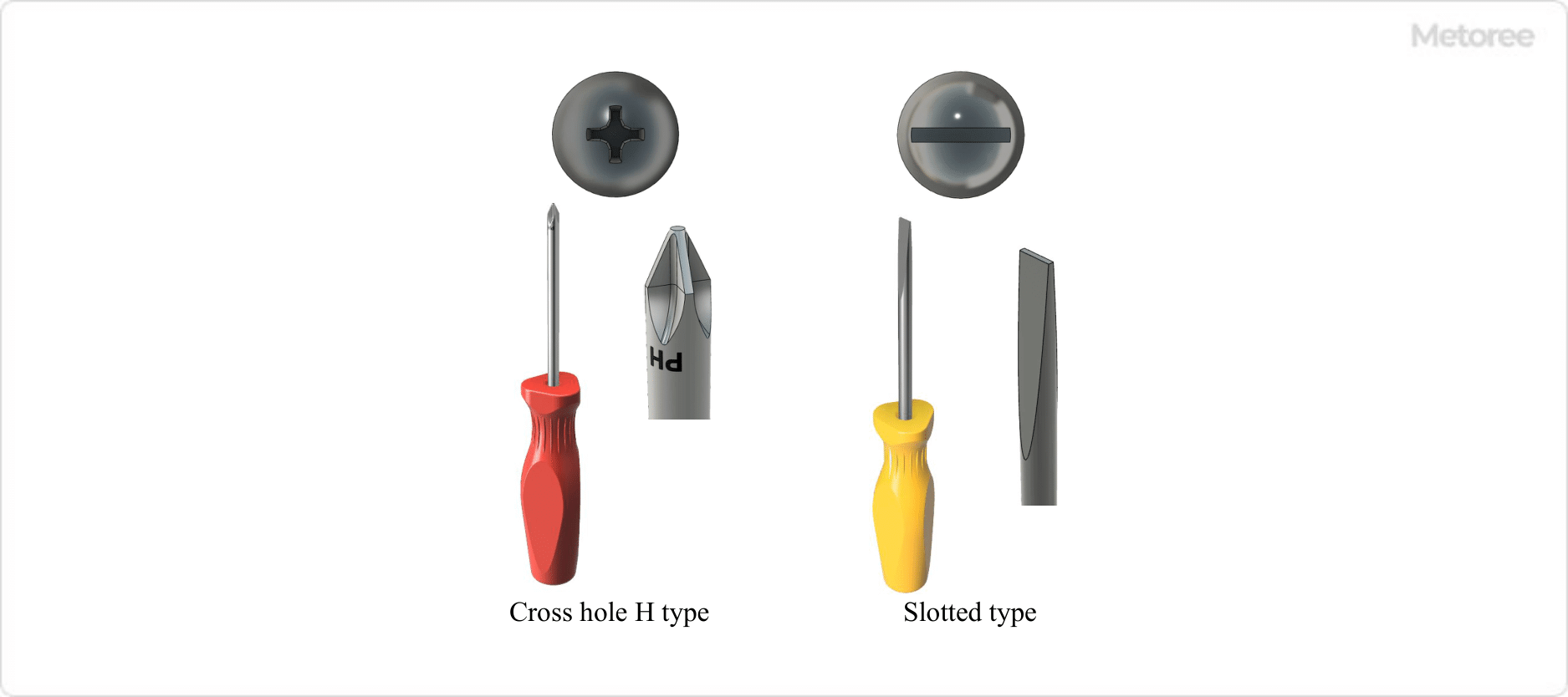

Small truss head screws are designed for direct fastening into tapped holes without the need for a nut, tightened using Phillips or flat-blade screwdrivers. The length of these screws is measured excluding the head height, a distinction important for accurate application.

Types of Small Truss Head Screws

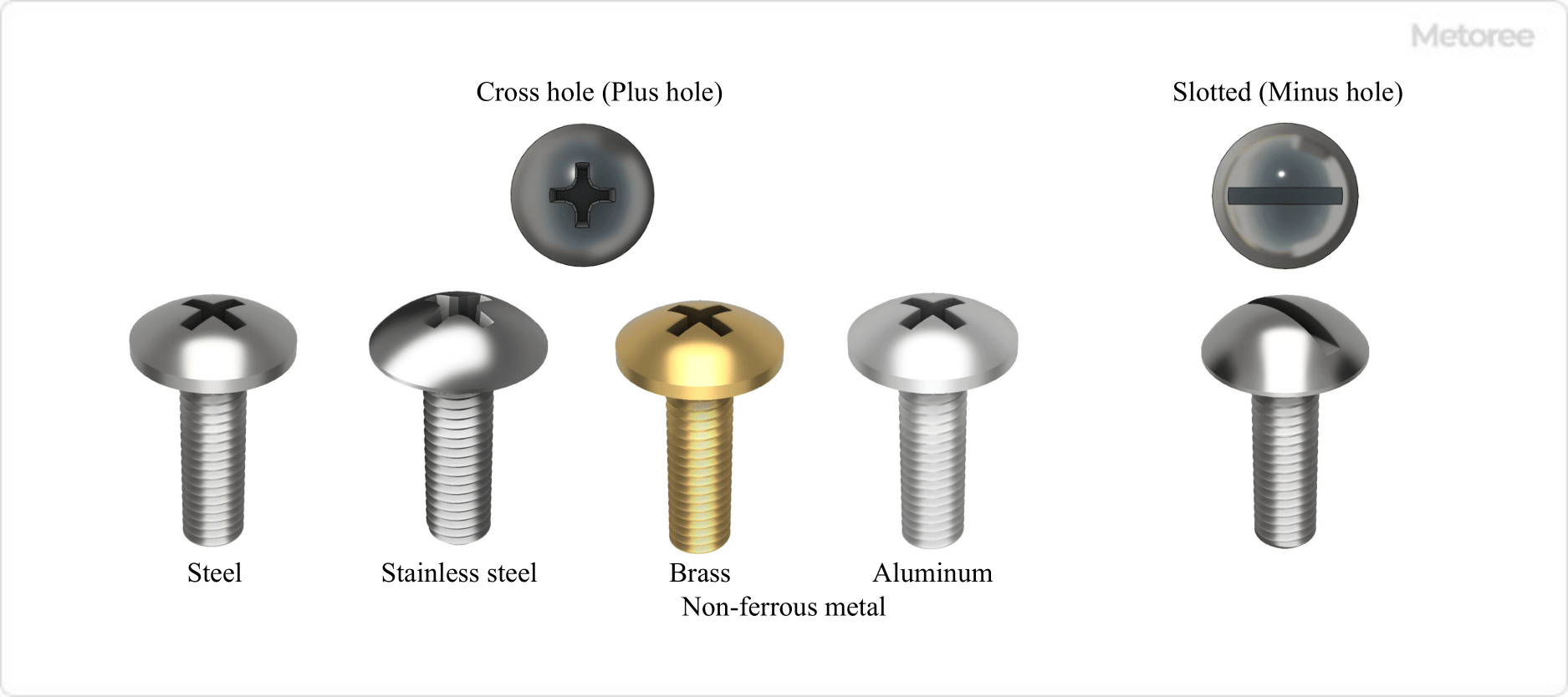

The classification of small truss head screws can be based on the head hole shape or material strength, as detailed below and in Figure 3.

Figure 3. Types, Materials, and Shapes of Truss Head Screws

Figure 3. Types, Materials, and Shapes of Truss Head Screws

1. Classification by Hole Shape of the Screw Head

Small truss head screws feature either a cross (Phillips or Pozidriv) or slotted head design, each requiring specific tools for tightening.

Figure 4. Truss Head Screw Head Hole and Tool Shape

2. Material (Strength Classification)

Materials range from steel and stainless steel to nonferrous metals, each classified by strength and adhering to specific standards.

Other Information on Small Truss Head Screws

Standards such as ANSI/ASME B18.6.3 govern the specifications for small truss head screws. Sizes typically range from M2 to M8, with recommended lengths from 4 to 60 mm.

List of 20 Small Truss Head Screw Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- China

- India

-

-

-

NBK America LLC

SSCMS-M5

Manufacturer Overview

NBK America LLC, founded in 2015 and based in King of Prussia, Pennsylvania, is an American manufacturer and a subsidiary of Japan's Nabeya Bi-tech Kaisha, specializing in mechanical components. Their product range includes couplings, like miniature shaft couplings for precision machine tools and semiconductor manufacturing equipment, special screws, such as vacuum application screws and other machine components. NBK offers finite automaton (FA) solutions, including wireless positioning units for production lines and setup operations. NBK provides machine component servicing, such as vibration resistance treatment and laser engraving. Services for couplings and special screws include coupling stainless steel screw alteration and screw length adjustment.

-

-

-

-

Manufacturer Overview

AMPG (Accurate Manufactured Products Group), established in 1987 and headquartered in Indianapolis, Indiana, USA, is a manufacturer of hard-to-find, custom, and architectural fasteners. The company's product line includes binding shoulder screws, binding machine screws, and bearing plates. It also offers made-to-order shoulder screws, socket head cap screws, and hex head cap screws that are precision manufactured to exacting specifications on Swiss lathes. It also designs, engineers, and manufacturers custom products to meet client requirements. It serves many industries and markets, including process manufacturers and aerospace.

-

-

-

-

-

U-BOLT-IT, INC.

Truss Head Screws

Company Overview

U-BOLT-IT, INC. is a manufacturer and distributor of fasteners and lifting hardware founded in 1988 and based in Houston, Texas. The company offers various standard and custom bolts, nuts, screws, and cables. These include eye and U bolts, hex nuts, cable assemblies, and button socket head screws in a wide range of materials and coatings/finishes. U-Bolt-It products are primarily used by clients in the industrial manufacturing, marine, consumer goods, and off-shore sectors.

-

-

-

-

-

Minerallac Company

TRUSS HEAD MACHINE SCREWS

Company Overview

Minerallac Company, based in the United States, is a well-established manufacturer of electrical hardware and fasteners since 1894. The company's comprehensive product range includes electrical boxes, conduit hangers, and cable connectors, meeting a wide range of customers needs. They provide extensive product offerings, effective and efficient packaging, service that maximizes economic efficiencies, and large array of American made products. They offer a comprehensive package of electrical hardware and fasteners for their distributor partners.

-

-

-

-

-

ACube Fasteners Pune

TRUSS HEAD SCREWS

Manufacturer Overview

ACube Fasteners Pune is a manufacturer of screws, bolts and special critical fasteners. Established in 2012, the company is based and headquartered in Pimpri-Chinchwad, Maharashtra, India. The company, an ISO 9001-2015 company, specializes in designing and producing many types of screws and fasteners for various applications. Its product range includes special screws and bolts, machine and hex screws, special and weld screws, self-tapping screws and rivets, serving industries such as construction, manufacturing, and automotive. ACube Fasteners offers services like customized fastener solutions and technical support.

-

-

-

-

-

Shenzhen Shi Shi Tong Metal Products Co., Ltd.

Truss Head Tapping Screw

Manufacturer Overview

Shenzhen Shi Shi Tong Metal Products Co. Ltd. is a manufacturer of non-standard screws and fasteners established in 2009 and headquartered in Guangdong, China. The company offers a range of screws, including stainless steel, titanium, iron, multi-stroke, and die screws. It also offers special-shaped screws, long screws, non-standard fasteners, and supporting hardware. The company provides custom-made special screws to meet customer specifications. It is ISO 9001:2015 certified, serving various industries, including aerospace, automotive, electronics, and medical devices.

-

-

-

-

-

Fong Prean Industrial Co., Ltd

Modified truss head wood screw

Manufacturer Overview

Fong Prean Industrial Co., Ltd, founded in Taiwan in 1968, is a manufacturer of screws and related tool accessories. The company's product portfolio includes self-tapping screws, tek screws, stainless steel screws, collated screws, and custom screws. Its products find application in outdoor walls, roofs and fences and indoor frames and ceilings. The company holds various international standard certifications, including CE, ISO, ETA, and TORXTTAP. It also offers expert guidance, product consultation, and customer support.

-

-

-

-

-

Shenzhen Heat Hardware Co., Ltd

Phillips Stainless steel truss head machine screw

Manufacturer Overview

Shenzhen Heat Hardware Co. Ltd, founded in the year 2003, and based in Shenzhen City, China, is a manufacturer and supplier of screws, bolts, and fasteners. Their product portfolio includes a diverse range of screws, bolts, and fasteners. The company offers one-stop customized solutions of screws, custom bolts, and fasteners for producing, designing, supplying, and exporting. The company is ISO-certified for environmentally friendly products. The products are used in various industries which include automotive, electronic, electric, communication, medical, and military projects.

-

-

-

-

-

ACube Fastener

Truss Head Screw

Manufacturer Overview

ACube Fastener, established in 2005, is a manufacturer, specializing in producing industrial fasteners and hardware components, headquartered in India. The company serves industries including construction, automotive, and aerospace, providing a wide range of solutions for various applications. Its diverse product portfolio, including screws, bolts, and nuts, made from various materials. It manufactures and exports various machine components and fasteners like socket head cap screw, coller bolt and screw, step bolts, and special customized screws as per customers drawing etc. It supplies multiple grade low carbon steel 4.6, 4.8, 5.6, 6.8, brass, copper, aluminium & alloy steel grade 8.8, 10.9.

-

-

-

-

-

Prince Fastener

Truss Head Machine Screw

Manufacturer Overview

Prince Fastener is a professional fastener manufacturer situated in Shanghai and Nan-tong Province, China. Its product line includes drywall screws, chipboard screws, machine screws, self-tapping screws, and self-drilling screws. The company utilizes advanced manufacturing equipment, such as head making machines, thread rolling machines, net furnaces, and various inspection tools like micro hardness testers and microstructure testers. The company has earned ISO (International Quality System) certification, attesting to its adherence to quality and standardized production processes.

-

-

-

-

-

Industrial Tools Agency

SELF DRILLING SCREW -TRUSS HEAD TYPE

Manufacturer Overview

Industrial Tools Agency (ITA) is an Indian ISO 9001 certified manufacturer of various fasteners that was established in 1976. Based in Bangalore, Karnataka, the company produces fastening tools and supplies such as socket and machine screws, nuts, pins, and anchors. These are used to secure or attach components and machines in the manufacturing operations of various industries, including the aerospace, energy and construction sectors. Along with its own products, ITA also stocks products from several brands including Unbrako, TVS Fasteners, Nordlock, and Helicoil.

-

-

-

-

-

Definite Metal LLP.

Truss Head Machine Screws

Manufacturer Overview

Definite Metal LLP., founded in Gujarat, India is a manufacturer of Brass and Copper Components including Brass Fasteners, Cable Glands, and Cable Gland Accessories. The company's product portfolio includes Hardware Components, Brass Precision Turned Components, Brass inserts, CNC Turned Components and Brass Valves. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. The company provides services such as Product Selection Guidance, Engineering Support, and Custom Manufacturing.

-

-

-

-

-

Huckleberrt

Stainless Steel Truss Head Screws

Manufacturer Overview

Huckleberry Lighting LLC founded in Eagle Mountain, Utah, USA, in 2021, is a manufacturer of holiday DIY lighting systems. The company’s product portfolio includes LED lights, wire crimp connectors, track couplers, and RGB lights. Its 48V system is installed without an electrician, supports 300 feet of lights in one run and without additional power injection points. Each light contains three warm white LEDs (2800K) and 3 RGB LEDs, making it bright. The company offers monthly payment plans with no hidden fees.

-

-

-

-

-

Bosch Rexroth

COUNTERSUNK-HEAD SCREW S8X25

Manufacturer Overview

Bosch Rexroth’s origins date back to 1795 and is now based in Lohr am Main, Germany. Bosh Rexroth is a manufacturer of industrial and mobile equipment control and motion products and systems. Bosch Rexroth’s products are divided into 10 technology segments. First is assembly technology which includes modular components. Next are electronic drives and controls which include CNC and motion control. Industrial hydraulics and linear motion technology follow. Mobile hydraulics, electronics, and IoT include solutions for mobile machines. Gear technology includes planetary gearboxes. The final four segments are molding and casting technology, tightening technology, resistance welding, and mobile robotics.

-

-

-

-

-

-

-

Jiaxing Chishing Precision Hardware Technology Co., Ltd.

Truss Head Self Tapping screw

-

-

-

-

-

ALL POINTS FASTENERS

Modified Truss head screws

-

-

-

-

-

SINSUN

head self-drilling screws

-

-

-

-

-

Suzhou Bilateral Import & Export Co.LTD

Slotted Truss Head Machine Screw

-

-

-

-

-

Resistant Metal Alloys LLP

Truss Head Screws

Distributor Overview

Resistant Metal Alloys LLP, established in 2007, is a global supplier headquartered in India, specializing in providing bolting solutions for critical applications across industries such as oil and gas, petrochemical, and power generation. The company as a bolting specialist is an exclusive brand name for high precision build fasteners in high tensile, corrosion resistant alloys, marine alloys and ASTM/ASME fasteners. The brand is exclusively owned and operated under the entity "Bolting Specialist". Its strengths lie in its comprehensive product range, including stud bolts, nuts, and specialty fasteners, and has obtained ISO 9001 certification.

-

-

Small Truss Head Screw Manufacturer Ranking

*Including some distributors, etc.Ranking as of April 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Dongguan Yuhuang Electronic Technology Co., Ltd. |

25.0%

|

| 2 | Shenzhen Shi Shi Tong Metal Products Co., Ltd. |

25.0%

|

| 3 | Prince Fastener |

25.0%

|

| 4 | Fong Prean Industrial Co., Ltd |

25.0%

|

Derivation Method

The ranking is calculated based on the click share within the small truss head screw page as of April 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

Newly Established Company

- NBK America LLC: 2015 (9 years ago)

- Dongguan Yuhuang Electronic Technology Co., Ltd.: 2010 (14 years ago)

- Shenzhen Shi Shi Tong Metal Products Co., Ltd.: 2009 (15 years ago)

Company with a History

- Industrial Tools Agency: 1976 (48 years ago)

- Fong Prean Industrial Co., Ltd: 1986 (38 years ago)

- U-BOLT-IT, INC.: 1988 (36 years ago)

Small Truss Head Screw Manufacturers in United States

*Including some distributors, etc.

Global Distribution of Small Truss Head Screw Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

India

India

|

5 | 35.7% |

China

China

|

5 | 35.7% |

United States of America

United States of America

|

4 | 28.6% |