10 Socket Bit Manufacturers in 2024

This section provides an overview for socket bits as well as their applications and principles. Also, please take a look at the list of 10 socket bit manufacturers and their company rankings.

Table of Contents

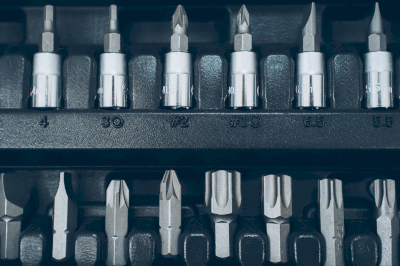

What Is a Socket Bit?

A socket bit is a tool designed for use with power drills and impact drivers. These bits come in various shapes and sizes to fit different types of power tools and are attached to the end of the rotating shaft of the tool for versatile applications.

Uses of Socket Bits

Socket bits are utilized in a wide range of power tools, including power drills, impact drivers, socket wrenches, and manual screwdrivers. Their applications extend from DIY projects to small-scale store renovations and large-scale construction work on commercial buildings.

Principle of Socket Bits

Socket bits are joined to the power tool by inserting them into the rotating shaft. Most socket bits are hexagonal, and there are several sizes for different tools. For instance, 5 mm, 6.35 mm, and 8 mm are common sizes for electric and air screwdrivers, while smaller electric screwdrivers may use 4 or 5 mm diagonals.

Other Information on Socket Bits

1. Standards of Socket Bits

There are two primary types of socket bits: A-type and B-type, differing in length from the groove to the tip. Domestic electric screwdrivers typically use B-type bits.

2. Heat Treatment Hardness of Socket Bits

Socket bits are classified into five hardness levels based on their intended use. The categories range from S and E (lowest hardness) to X (highest hardness), each suited for specific applications like high-impact tools, tapping screws, wood screws, self-drilling screws, and precision small screws.

3. Types of Hexagonal Socket Bits

Hexagon socket bits, used for fastening hexagonal bolts, come in various types:

- Shaft Press-fit Type: These bits have separate hexagonal sockets and shaft parts and are mainly used in building equipment applications.

- Integral Molded Bits: One-piece design with high rigidity, suitable for small-diameter bolts and torque-controlled fastening, but prone to breakage due to stress concentration.

- Bit Interchangeable Type: Featuring replaceable hexagonal shafts, these bits are durable but larger and heavier due to their replacement structure.

- Socket adapters: Conversion adapters are used to connect hexagonal socket bits to square-shaped impact wrenches or socket wrenches with hexagonal holes, such as impact drivers. They are best used temporarily due to increased backlash from multiple joints.

List of 10 Socket Bit Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- India

- Japan

- Taiwan

-

-

-

TOP Kogyo Company, Ltd.

UNIVERSAL SHORT SOCKET BIT

Manufacturer Overview

TOP Kogyo Company, Ltd., a company founded in 1939 and headquartered in Sanjo City, Japan, is a manufacturer and supplier of hand tools. The company's product portfolio includes adjustable wrenches, PVC cutters, pliers, riveters, and various other hand tools. Hand tools find applications in various industries, including plumbing, metalworking, woodworking, HVAC (Heating, Ventilation, and Air Conditioning), and DIY/home improvement. The company also offers customer services, including customer support, product information, and a product catalog. The company is ISO 9001:2015 certified for its quality management system.

-

-

-

-

-

A-KRAFT Tools

Socket & Bit Set

Manufacturer Overview

A-KRAFT, located in Taiwan, is a hand tools supplier designed exclusively for export since 1988. The company's product line includes primarily 1/4”, 3/8”, 1/2”, 3/4” drive sockets, accessories, and various types of combination wrenches and much more. They supply products to many famous tools manufacturers in Europe as their OEM, ODM supplier. Their products meet International standards of DIN and ANSI. With a strong in-house R&D team which helps launch new products to strengthen the market competition for the customers. Specializing in selling combination sets of these tools in cases that are convenient to use for the homeowner or professional repairman.

-

-

-

-

-

Torcstar

Impact Hex Bit Sockets

Manufacturer Overview

Torcstar, founded in Maharashtra, India, in 1994 is a manufacturer of Hydraulic Tools, Pneumatic Tools and Electric Tools. The company's product portfolio includes General Tools, Hydraulic Torque Wrenches, Pumps, Hydraulic Bolt Tensioners and Lifting Tools. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. The company provides services such as Product Selection Guidance, Engineering Support, New Product Design and Development and national distribution.

-

-

-

-

-

E Ding Co.,Ltd.

Bit Sockets

Manufacturer Overview

E Ding Co., Ltd. is a tool manufacturer and exporter, based in Taichung City, Taiwan, operating since 1970, They specialize in hand tools and pneumatic devices, primarily air ratchets, air angle grinders, air impact wrenches, and air hammers, used in various industries including automotive maintenance, petrochemical, construction, and general industry. In addition to distributing products under their own branding, they also provide original equipment manufacturer and original design manufacturer services for customers.

-

-

-

-

-

Gurukripaa Tools Private Limited.

Socket Bit

Manufacturer Overview

Gurukripaa Tools Private Limited, founded in 2012 and situated in Maharashtra, India, is a manufacturer, importer, and exporter of impact sockets, crowfoot wrenches, and socket bits. The company’s products include magnetic nut setters, flared end crowfoot wrenches, and universal impact wrenches. The products are designed in varying shapes and sizes to perform tasks in different dimensions and applications, such as construction and manufacturing. It exports its products to countries such as the Middle East, Canada, and the USA and imports from Taiwan.

-

-

-

-

-

Tulex Industrial Tools

ALLEN BIT SOCKET (HEX BIT SOCKETS)

Manufacturer Overview

Tulex Tools, established in 2000 and based in Maharashtra, India, is a manufacturer and exporter of impact sockets and torque tools. The company offers bolting system for mining, engineering, transportation, and power plant industries as well as impact sockets that cater to various applications in the automotive and hydraulic sectors. Tulex Tools also provide non-sparking accessories, softer than conventional tools that require special handling for fire prevention. The company seeks to deliver superior workmanship toward technical efficiency to various industries across countries.

-

-

-

-

-

ARES & T TOP HAND TOOLS CO.,LTD

Bit Series

Manufacturer Overview

ARES & T TOP HAND TOOLS CO.,LTD is a manufacturer and supplier of hand tools that was established in 1979 and is headquartered in Taichung, Taiwan. The company produces a wide range of tools, including wrenches, sockets, pliers, and automotive tools. Its products such as loose sockets, socket sets (BMC), socket sets (metal case), impact sockets and accessories, and impact socket sets are used by a number of automotive repair shops, industrial maintenance facilities, and DIY enthusiasts around the world. The company also provides a range of services, including OEM manufacturing, sales, and support.

-

-

-

-

-

CTA Manufacturing

Bit Socket Set

Company Overview

CTA Manufacturing, originally named Classic American Tools, founded in 1978, and headquartered in Carlstadt, New Jersey, USA, is a manufacturer and a distributor of automotive specialty tools. Its product line encompasses diverse automotive specialty tools, which are categorized into offerings such as engine tools, brake tools, oil & exhaust tools, suspension tools, and body & interior tools. These tools play essential roles in engine repair, brake system maintenance, oil changes, suspension system repair, and car body and interior upkeep, meeting the diverse needs of professionals in the automotive service sector.

-

-

-

-

-

-

-

Eastman Cast and Forge Ltd.

Socket Spanners

Company Overview

Eastman Hand Tools, a part of the Eastman Group, began its operations in 1989, as a manufactuer of utility products in accordance with international standards (DIN, JIS, ANSI), based in India. The company’s state-of-the-art infrastructure empowers it to produce over 24 million tools per annum, catering to a wide range of industries. Their product portfolio encompasses a wide range of offerings, including hand tools, OEM tool kits, and cleansing solutions. With touch points in 35+ countries across USA, Europe, Asia, and the CIS region, including key markets like Russia and Ukraine.

-

-

Socket Bit Manufacturer Ranking

*Including some distributors, etc.Number of Employees

- TOP Kogyo Company, Ltd.: 160

Newly Established Company

- Gurukripaa Tools Private Limited.: 2012 (12 years ago)

- Landmark Crafts Private Limited: 2007 (17 years ago)

- A-KRAFT Tools: 1988 (36 years ago)

Company with a History

- TOP Kogyo Company, Ltd.: 1939 (85 years ago)

- E Ding Co.,Ltd.: 1970 (54 years ago)

- A-KRAFT Tools: 1988 (36 years ago)

Global Distribution of Socket Bit Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

India

India

|

4 | 57.1% |

Taiwan

Taiwan

|

2 | 28.6% |

Japan

Japan

|

1 | 14.3% |