162 Pipe Fitting Manufacturers in 2024

This section provides an overview for pipe fittings as well as their applications and principles. Also, please take a look at the list of 162 pipe fitting manufacturers and their company rankings. Here are the top-ranked pipe fitting companies as of April, 2024: 1.High Pressure Equipment Company, 2.WeldFit, 3.Xylem Inc..

Table of Contents

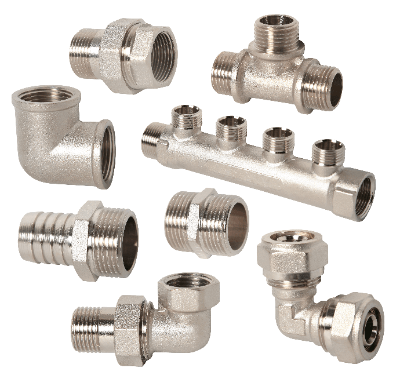

What Is a Pipe Fitting?

A pipe fitting is a component used to connect different types of pipes.

It is one of the main methods of connecting pipes, but it also serves not only to extend pipes but also to change the direction of routes, branch or join pipes, enlarge or reduce the diameter of pipes, and seal the ends of pipes. Some pipe fittings are removable after connection, while others are not. In terms of ease of maintenance, it is recommended that removable pipe fittings be used for part of the piping.

It is very convenient to use both types of fittings, because while fixing the entire pipe increases its strength, doing so makes it impossible to replace only the faulty part. There are also various shapes, materials, and connection methods. It is necessary to select the appropriate pipe fitting according to the application of the fitting and the type and material of the piping.

Uses of Pipe Fittings

A pipe fitting is a component that connects pipes that transport gases and liquids. Therefore, a pipe fitting is used in facilities that use piping.

Specifically, they are used in water supply facilities, hot water supply facilities, drainage pipes, ventilation pipes, gas piping, fire prevention piping, cold and hot water circulation systems for air conditioning, agricultural water piping, chemical plant piping, and hydraulic piping. In addition to fluid piping, pipe fittings are also used for cable protection in the electric power and telecommunications fields, and are expected to improve construction work efficiency in the future as the use of utility poles is promoted.

Principle of Pipe Fittings

A pipe fitting is generally connected in two ways: flanged and screwed.

1. Flange Method

In the flange method, pipes are connected using a flange, which is a ring of two planes fixed to each other with a fitting in between. Since the fittings are secured to each other via the flanges and tightened with bolts, this method is characterized by high durability.

2. Screw-in Method

The screw-in method connects pipes by making a cut at the end of the pipe, creating a spiral groove in the groove, and cutting a spiral groove that matches the end of the pipe to be connected. This method is simpler than the flange method and is used for relatively small pipes.

Types of Pipe Fittings

A pipe fitting has a wide variety of shapes and connection methods due to its extremely wide range of applications. In many cases, products from different manufacturers can be connected to each other, but it is important to check for compatibility before use.

The main types of Pipe Fitting are as follows:

- Socket

Sockets are used to connect straight pipes of the same diameter with the same external threads. - Nipple

Connects straight pipes of the same diameter with the same internal thread. - Coupling

Directly connects straight pipes of the same diameter without threading. - Elbow

Used to bend the direction of piping. Bending angles include 45°, 90°, and 180°. - Bend

Used to bend the direction of piping. Compared to elbows, bends have a larger radius of curvature. - Reducer

Used to connect straight pipes of different diameters. - Cheese

Pipe Fitting with a T-shape to branch a pipe into a T-shape. - Cross

Pipe Fitting in the shape of a cross, which branches a pipe in four directions. - Cap

A cap is connected to a pipe by placing it over the pipe or by connecting it to the outer thread of the pipe to seal the end of the pipe. - Plug

A plug is connected to a pipe by fitting it into the pipe or connecting it to the inner thread of the pipe and sealing the end of the pipe.

Other Information on Pipe Fittings

1. How to Connect Pipe Fittings

Pipe fitting connection methods include threaded, welded, and flanged.

Threaded type

The pipe fitting is threaded, and the piping person threads it out for use. Since this connection method is removable, it is easy to repair and maintain.

Welded Type

The pipe fitting is inserted into the pipe and welded by insertion welding, or butt-welded by butt-welding the ends of the pipe and fitting against each other. This type of welding is stronger and more reliable than the screwed-in type.

Flange Type

Pipe flanges are connected with a bottle and nut.

Shafting Type

The pipe fitting is inserted into the pipe and welded by insertion is connected by wedging the sleeve of the pipe fitting into the pipe. When using a pipe fitting, the appropriate pipe fitting should be selected based on the shape, connection method, material, and size (pipe diameter) as described above.

2. Threaded Sealing Material

When using a screw-in pipe fitting, a sealing material is required. Sealant prevents leakage from the joint. There are two types of sealing materials: liquid type and tape type.

In the case of screws, even when fastened, a gap exists between the outer and inner threads. The role of the sealant is to fill the gap at the screw.

List of 162 Pipe Fitting Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- Austria

- Canada

- China

- France

- Germany

- India

- Italy

- Japan

- Switzerland

- United Kingdom

-

-

-

Xylem Inc.

Fittings

Manufacturer Overview

Xylem Inc. was incorporated in 2011 and is headquartered in Washington, District of Columbia. Xylem engages in the design, manufacture, and servicing of engineered products and solutions for the water and wastewater applications across global markets. Xylem operates through three segments: water infrastructure, applied water, and measurement & control solutions. Xylem’s water infrastructure segment offers numerous products such as water pumps, filtration, disinfection, and biological treatment equipment. Xylem’s applied water segment distributes pumps, valves, heat exchangers, controls, and dispensing equipment systems. Xylem’s measurement & control Solutions segment offers devices such as smart meters, networked communication devices, data analytics, test equipment, controls, sensor devices, and software and managed services.

-

-

-

-

-

MicroStrain, a LORD Company

Industrial Brass Fittings

Manufacturer Overview

MicroStrain is based in Williston, Vermont, and is an American manufacturer of inertial and wireless sensors originally established in 1987 before being acquired by HBK in 2019. The company produces various industrial and tactical-grade sensors, wireless sensor network devices, and data analysis software. Its products include battery powered wireless 3-axis accelerometers with a rugged and weather-proofed shell, cloud-based platforms for sensor data management or analysis, and software for wireless sensor network control purposes. The company's products are mainly used by clients in the aerospace, automation, and construction industries.

-

-

-

-

-

Anver Corp.

Vacuum Hose Barb Fittings

Manufacturer Overview

ANVER Vacuum Material Handling Specialists, established in 1975 and located in Elk Grove Village, Illinois, USA, is a manufacturer and supplier of vacuum tube lifting systems and vacuum lifting equipment. The company's product range includes vacuum tube lifters, lifting pads, grippers, generators, and system components, catering to diverse industries such as manufacturing, aerospace, automotive, food and beverage, and material handling. The company’s services entail, testing and certification, supply chain management, and technical support. The company also holds ISO 9001:2015 certification, an indication that it exceeds expectations in quality and service.

-

-

-

-

-

-

-

High Pressure Equipment Company

FITTINGS

Manufacturer Overview

High Pressure Equipment Company, part of Graco Inc., established in 1954 in the United States, is a manufacturer of high pressure valves, fittings and tubing. The company manufactures high pressure valves, fittings and tubing with superior standards, delivered with the shortest lead times, and priced to ensure its customers' success. Today, it features a broad product portfolio capable of handling pressures up to 150,000 psi and carries an extensive inventory allowing it to offer same day shipping of many items. It also offers a complete line of reactors and pressure vessels and a recently expanded family of pumping systems and generators.

-

-

-

-

-

WeldFit

TAPPING FITTINGS

Manufacturer Overview

WeldFit, established in 1968 and headquartered in Houston, Texas, USA, is a manufacturer of various pipeline products. The comprehensive product portfolio includes automated pipeline pigging systems, traditional pig launchers/receivers, quick opening closures, and pig passage indicators. These products are designed to enhance the efficiency and safety of pipeline operations. The automated pipeline pigging systems ensure the effective cleaning and maintenance of pipelines, reducing the risk of blockages and improving fluid flow. These products find applications across various industries, including oil and gas, petrochemicals, and water treatment. The company has ISO 9001:2015, ASME S, U, R, and NB certifications.

-

-

-

-

-

ASC Engineered Solutions, LLC

Pipe Joining Systems

Manufacturer Overview

ASC Engineered Solutions is based in Waynesboro, Pennsylvania. ASC serves the mechanical & plumbing systems, commercial & residential, mining, food & beverage, industrial, fire protection, oil & gas, energy & power, and water & wastewater industries as a procure and repair servicer. ASC is ISO 9001:2015 certified. A sample of ASC’s offerings include fire protection & fabrication products such as fabrication equipment and seismic bracing, flow control such as commercial& residential valves, performance products such as engineered pipe supports & snubbers, pipe joint systems such s grooved and high pressure fittings, as well as press products and support systems.

-

-

-

-

-

Pipe Fittings Direct

PIPE NIPPLES

Manufacturer Overview

Pipe Fittings Direct , established in 2013 and headquartered in Edgarton, Wisconsin, USA, is a manufacturer of pipe fittings for the exhaust and irrigation markets. The company offers a diverse range of product varieties, including elbows, couplings, and flanges, all designed to ensure precise connections and efficient fluid flow. These fittings boast robust durability and adaptability, resulting in long-lasting performance and reduced maintenance needs. Mainly utilized in exhaust systems and irrigation setups, the products find application across industries such as automotive, agriculture, and landscaping to offer essential components, providing efficient solutions for exhaust and irrigation needs.

-

-

-

-

-

NIBCO INC.

Fittings

Manufacturer Overview

NIBCO INC. was founded in 1904 in Elkhart, Indiana. NIBCO is a worldwide manufacturer of flow control system solutions for residential, industrial, marine, and irrigation markets. NIBCO is ISO 9001:2015 certified. NIBCO products segments include system management including air separators and isolation strainers, fittings including metal and plastic fittings, tools, pipes, & accessories, and valves which includes among others, press tools, push tools, ball valves, boiler drains, butterfly valves, check valves, and gate valves.

-

-

-

-

-

AutoVac Industrial Vacuum & Air Systems

Pipe Fittings

Manufacturer Overview

AutoVac Industrial Vacuum & Air Systems, generally known as AutoVac, was founded in 1989 and centered in the town of Lake Tahoe, Nevada. AutoVac serves automotive, aerospace, medical, dental, and industrial manufacturing industries. AutoVac is a designer for manufacturing and production vacuum systems. AutoVac uses CAD to design systems such as factories and industrial production factoring in material cost, installation and operation labor, and electrical usage. Autovac can install or provide installation supervision, commissioning support, and new product development and prototyping.

-

-

-

-

-

Available Plastics, Inc.

Furniture Grade PVC Pipe & Fittings

Manufacturer Overview

Available Plastics was founded in 1978 and is headquartered in Huntsville, Alabama. The company is a manufacturer of custom and standard PVC components for commercial and individual customers. The company’s product segments include furniture grade and industry-standard PVC pipes and tubings, Duracore plastic cores, and central vacuum tubing. The company also produces custom extrusion profiles and custom banners and graphic hanger shapes. Company services include injection molding, custom plastic fabrication, and assembly, cleaning for medical and cleanroom applications, and custom coloring options.

-

-

-

-

-

Champion Fiberglass, Inc.

Pipe Fittings

Manufacturer Overview

Champion Fiberglass was founded in 1988 and is headquartered in Spring, Texas. The ISO9001, ISO 14001, and ISO 45001 certified company is a supplier of fiberglass conduit and strut to the industrial, electrical, and mechanical markets. The company’s products are often used in tunnels and bridges, data centers, chemical plants, and wastewater treatment facilities. Under its Champion label, the company sells products in two categories: electrical and mechanical. Electrical products include fiberglass ducts, flame shield phenolic conduit, and bridge hangers. Mechanical products include struts and bridge drains.

-

-

-

-

-

Fluid Transfer Systems, Inc.

Pipe Fittings

Manufacturer Overview

Fluid Transfer Systems, Inc was founded in 1971 and is headquartered in Novi, Michigan. Fluid Transfer Systems supplies fluid handling equipment for many industries including the automotive and agricultural. Fluid Transfer Systems’s equipment categories include agitators, filtration, plural component mixing, pressure tanks & packages, pumps & spray packages, regulators, and spray guns. Fluid Transfer Systems also offers complete custom systems such as pump circulation systems, 2K electronic proportioners, paint kitches, and finishing systems.

-

-

-

-

-

Bonney Forge Corporation

Pipe Fittings

Manufacturer Overview

Bonny Forge was originally founded in 1876 and is based in Mount Union, Pennsylvania. The company isis a manufacturer of fittings, valves, and other products used in petrochemical, refining, power, energy, and industrial piping markets. The company’s five product lines are Forged Steel Fittings and Unions, Forged Steel Branch Connections, Forged Steel Valves, Cast Steel Valves, and Forged Ball Valves. The company uses CAD to allow customers to customize desired specifications of machines, such as valve size, Cv coefficient, and material.

-

-

-

-

-

White Racker Co.

Pipe Fittings

Manufacturer Overview

While Racker Company was founded in 1894 and is headquartered in Elk Grove Village, Illinois. The company is a manufacturer servicer, and design engineer of plumbing and CNC machining-related needs for residential, commercial, and industrial customers. The company’s three product categories are marble toilet partition hardware, commercial plumbing, and CNC machining. CNC machining services include aluminum and brass casting, CNC milling, and CNC turning and boring. Marble toilet partition hardware offerings include stall door hardware, stirrups and angles, standards and rails, and anti-theft fasteners. Commercial plumbing products include pipe supports, chrome plated fittings and pipes, and urinal fittings.

-

-

-

-

-

Hydrasearch Company LLC

Pipe Fittings

Manufacturer Overview

Hydrasearch Company LLC is a designer and manufacturer of fluid control and transfer products for the maritime industry that was established in Stevensville, Maryland, in 1962. The company’s product lineup includes fluid control components for defense applications such as quick disconnect couplings, underwater hull penetrators, and submarine hose assemblies. It also offers recreational marine hardware such as raw water strainers, sounding tube deck fittings, and vent check valves. The company chiefly serves the defense and recreational boating industries, with additional clients in the American commercial sector.

-

-

-

-

-

Western Enterprises

National Pipe Thread Fittings

Manufacturer Overview

Western Enterprises provides products for control, storage, and transmisson of gases to industrial and medical markets. They are located in the United States of America in the state of Ohio in the city of Westlake. The company was founded in the year 1952 and strives to provide high quality produccts such as medical regulators, flowmeters, and pipe fittings. Many of their products are useful for appliances such as air conditioners and heaters.

-

-

-

-

-

The Briggs Company

Pipe Fittings

Manufacturer Overview

The Briggs Company is headquartered in New Castle, Delaware, with sales offices in Virginia and Pennsylvania. The company is a custom manufacturer of transfer-related products and coupling retention technology for all industries, also offering design, fabrication, and distribution services. The company is a member of the Hose Safety Institute and NAHAD, the National Association of Hose and Accessories Distribution. The company offers pipe & fittings, hoses and assemblies, industrial fittings & disconnects, and other industrial rubber products.

-

-

-

-

-

Lokring Technology

Pipe Fittings

Manufacturer Overview

LOKRING Technology is headquartered in Willoughby, Ohio as an ISO 9001:2015-certified manufacturer of offload and gas connection components. The company serves numerous industries including medical devices, railroads, pipelines, and marine industries across the globe. The company’s products include adapters, caps, couplings, elbows, unions, and other connectors according to the needs of each market. The company utilizes an external distribution network for customers while also providing design guides, installation services, and installation tools.

-

-

-

-

-

Cash Acme

Pipe Fittings

Manufacturer Overview

Cash Acme is based in Atlanta, Georgia and has a history of over 100 years and is part of the RWC family of brands also including SharkBite, HoldRite, John Guest, and EZ-FLO. Cash Acme is a manufacturer of water control valves for residential, commercial, and industrial plumbing applications. Cash Acme products include pressure regulating valve, temperature & pressure relief valves, thermostatic mixing valves (TMVs), back flow preventers, general plumbing & heating, as well as other applications.

-

-

-

-

-

Viega USA

All Categories

Manufacturer Overview

Viega has a history of over 120 years and is based in Broomfield, Colorado. Viega is a developer and producer of hardware and industrial tools and pipe fitting technology. Viega’s equipment specializes in materials such as copper, stainless, polymer, lead bronze, and cupronickel. Some of Viega’s product listings include elbows, tees, adapters, flanges, caps, unions, couplings, reducers, branch connectors, tubing, manifolds, stub-outs, closet adapters, outlet boxes, press sleeves, closet risers, ballcock nuts, fasteners, sealing elements and gaskets.

-

-

-

-

-

Micromold Products, Inc.

PTFE Piping Systems & Accessories

Manufacturer Overview

Micromold Products was established in 1954 and headquartered in Yonkers, New York. The company is a manufacturer of a broad line of corrosion-resistant plastic products, specifically Kynar, polypropylene, nylon, and Kel-F, for process industries. The company has developed proprietary manufacturing processes for PTFE and PFA machined parts and weldments. The company’s product line includes a complete line of dip pipes, sparges, valves, strainers, and piping systems. The company makes a full line of CNC machined parts for process industry OEMs including PTFE, PEEK, and UHMW polyethylene ball and butterfly valve seats, pump seals, and instrumentation components.

-

-

-

-

-

Superior Products, Inc.

Superior Products

Manufacturer Overview

Superior Products, LLC is based in Cleveland, Ohio. Superior Products is a manufacturer and logistical provider of gas management systems and parts for customers globally, with many customers in industrial, medical, and specialty gas management markets. In addition Superior Products is certified ISO 9001:2008 Superior’s product offerings differ according to industry needs, with parts including couplers, valves, other connectors, gas mixers, and more. Additionally, Superior Products can custom engineer products to custom specifications in stainless steel, aluminum, brass, plastic, and titanium.

-

-

-

-

-

Carlisle Fluid Technologies

Pipe Fittings

Manufacturer Overview

Carlisle Fluid Technologies is a conglomerate over many brands including BGK, Banks, DeVilbiss, Hosco, MS, and Ransburg. Through these brands, Carlisle Fluid Technologies globally distributes to industries such as aerospace, automotive OEM, automotive refinishing, general industrial, glass, protective coatings, and wood, solutions for numerous applications such as fluid and sealing needs. Carlisle Fluid Technologies’s product lines include diaphragm pumps, automatic applicators, air filtration, air regulators, hose and tube fittings, gas curing, inspection systems, nozzle cleaning systems, and more.

-

-

-

-

-

J.W. Winco, Inc.

Pipe Fittings

Manufacturer Overview

J.W. Winco was originally founded as Ganter in 1894 in Germany. Winco specializes in parts manufacturing. Parts offerings the operating parts segment including handles, adjusting, and positioning parts; clamping parts segment featuring tensioning, clamping, switching, and levers; and finally the machine parts segment with indexing, locking, mounting, connecting elements, guides, spindles, rollers, magnets, casters, and wheels. Winco’s complete catalog contains over 75,000 standard parts. Winco is also ISO 9001 certified. Winco offers free CAD downloads and technical documentation for many arts.

-

-

-

-

-

Poux Plastics

Pipe Fittings

Manufacturer Overview

Poux Plastics Inc. is an American manufacturer of PVC fittings established in 1978 and based in Cochranton, Pennsylvania. The company offers various standard and custom PVC fittings including insert couplings, transition fittings, starter tees, and reducer adaptors. Its products have applications in farming irrigation and drainage systems, water transfer, and dewatering operations at mining sites. Poux Plastics products are mainly used by clients in the agricultural, oil and gas, mining, and construction sectors.

-

-

-

-

-

Busada Manufacturing Corporation

Pipe Fittings

Manufacturer Overview

Busada Manufacturing Corporation, founded in 1950, is a family- operated, small manufacturer of plastics. They are headquartered in Louisa, Virginia and specialize in creating rigid thermoplastic transparent tubing that is resistant to shocks, chemicals, weather, and aging. They also make clear plastic butyrate pipe, which is transparent, rigid, weather resistant, and UV stable. This material is used in pneumatic transportation, water treatment plants, sight glasses, and various other applications.In the production of their goods, they use ingredients like cellulose acetate butyrate, Spectar Stratus, and FDA-approved butyrate.

-

-

-

-

-

HART Industrial Unions, LLC

Best-In-Class Manufacturer of Speciality High Pressure O-Ring Pipe Unions

Manufacturer Overview

HART Industrial Unions, LLC, founded in 1985 and located in Berlin, Connecticut, is a manufacturer and supplier of industrial pipe fittings. Its product range comprises dielectric insulated unions, copper sweat tube unions, female threaded unions, hammer lug unions, and orifice unions, serving the needs of the piping industrial market. Its O-ring unions are employed when piping requirements necessitate a flat face seat for making and breaking the pipeline. The products are utilized to facilitate secure connections, efficient fluid flow, and operations within industrial piping systems.

-

-

-

-

-

Bellows Systems, Inc.

Pipe Fittings

Manufacturer Overview

Bellows Systems, Inc. (BSI) is an American ISO 9001 and AS9100D certified manufacturer of metal bellows and expansion joints originally established in 1978 as a subsidiary of Bellows Manufacturing and Research, Inc. They have been operating as a standalone company since 2016. Based in Houston, Texas, the company produces exhaust bellows and manifolds, metal and fabric expansion joints, and metal bellows in various materials and sizes. These have applications in the water and wastewater, power generation, defense, and automotive industries. BSI offers additional product engineering, fabrication, and testing services for unique customer projects.

-

-

-

-

-

Precision Fittings, Inc.

Pipe Plugs

Manufacturer Overview

Precision Fittings, Inc., founded in Wellington, Ohio, in 1947 is a manufacturer of pipe plugs and special cold-formed and screw-machined parts. The company's product portfolio includes O-Ring Plugs, Aluminum Set Screws, Magnetic Plugs, Zero Leak Fittngs, and Hydraulic Pipe Plugs. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation. The company provides services such as Product Selection Guidance, Engineering Support, New Product Design and Development and Custom Manufacturing.

-

-

-

-

-

Beswick Engineering Co., Inc.

Pipe Fittings

Manufacturer Overview

Beswick Engineering was founded in 1964 as an engineering consulting firm. Beswick now operates out of Greenland, New Hampshire. Berwick serves the medical devices, aerospace, analytical instruments, bomb, gas, & narcotic detection equipment, semiconductor, dental, hydrogen fuel cell, industrial robot & automation, inkjet, 3D printing, and packaging & food packaging machinery industries. Beswick offers tubing, tubing clamps, cylinders, compression fitting accessories, filters, mufflers, breathers, orifice restrictors such as drilled orifice fittings and sapphire orifice fittings, valves, regulators, and quick disconnects. Beswick also offers custom design options.

-

-

-

-

-

Ohio Medical LLC

Fittings

Manufacturer Overview

Ohio Medical Parts originated in 1910 as Ohio Chemical and Manufacturing Company in Cleveland, Ohio. Today Ohio Medical is a producer of medical air and vacuum pumping systems as well as medical suction and oxygen therapy devices. Ohio Medical services the medical device, medical gas, construction/renovation, ambulatory surgery center, industrial, and OEM solutions industries. Ohio Medical devices are manufactured in an ISO 13485 registered and FDA regulated medical device manufacturing facility. Product offerings include medical devices such as flowmeters, hoses, gas regulators, and suction regulators, as well as medical gas devices such as medical gas systems, vacuum pumps, air compressors, and medical gas accessories.

-

-

-

-

-

Speed Field Services

Pipe Fittings

Manufacturer Overview

Speed Field Services, founded in 2014 and headquartered in Baytown, Texas, is a manufacturer of standard and custom spill containment products. The company offers a range of essential products, including berms, liners, and pipes, all crafted from geomembrane materials such as PE, Coolguard, XR5, vinyl, PVC, RPP, and RPE. Moreover, its services extend to custom fabrication and installation of HDPE, PVC, CPP, and polypropylene products, providing tailored solutions, and serving the marine, mining, and agricultural industries.

-

-

-

-

-

Reading Technologies, Inc

Pipe Fittings

Manufacturer Overview

Reading Technologies, Inc., based in Reading, Pennsylvania, USA, has been a manufacturer and supplier of air treatment solutions since 1987. They offer a diverse range of products, including refrigerated dryers, desiccant dryers, and hybrid dryers for removing moisture from compressed air. Their air filters, such as particulate filters, oil mist filters, and coalescer filters, ensure the removal of contaminants to improve air quality. Additionally, the company provides other compressed air treatment products like aftercoolers, pressure regulators, and moisture indicators to maintain the performance of compressed air systems.

-

-

-

-

-

Coronet Parts Mfg. Co., Inc.

Pipe Fittings

Manufacturer Overview

Coronet Parts Manufacturing Company Inc. was founded in the early 1960s and headquartered in Brooklyn, New York. The company is a custom manufacturer of industrial hardware and fittings serving the automotive industry and plumbing industry among others. The company’s product lines include fittings, valves, assemblies, and other tools. Plumbing specialty items include tank levers, flood stoppers, and supply tubes. Assorted tools include tube cutters, bending tools, flaring tools, and related parts.

-

-

-

-

-

Spiral Manufacturing Co., Inc.

Spiral pipe

Manufacturer Overview

Spiral Manufacturing, established in 1962, and headquartered in Minneapolis, Minnesota, is a manufacturer and supplier of spiral pipe and high pressure products in various forms for project and industrial needs. Their product range includes spiral ducts, fittings, and accessories. These products are used in HVAC (Heating, Ventilation, and Air Conditioning) systems for efficient air distribution, ventilation, and ductwork installations in various residential, commercial, and industrial buildings for optimal airflow, energy efficiency, and improved indoor air quality in industrial and commercial settings.

-

-

-

-

-

Seelye Acquisitions, Inc.

Industrial Pipe Fittings On Seelye Acquisitions, Inc.

Manufacturer Overview

Seelye, Inc. includes DJ Plastics and Tefen Products, USA. Seelye is a manufacturer of thermoplastic welders and welding-related equipment. Seelye has 3 product segments: hot air plastic welders, Tefen fittings and products, and DJ custom tank fabrication. Hot air plastic welders include plastic welders, thermoplastic welding rods, plastic welding tips, welder elements, welder replacement parts, optional equipment, and master appliance heat guns. Tefen fittings and products include tight push fittings, barb block fittings, general industrial accessories, and air blow guns. DJ Custom tank fabrication examples include plating tanks, dip tanks, and water holding tanks among others.

-

-

-

-

-

TITAN Metal Fabricators

Pipe Fittings

Manufacturer Overview

TITAN Metal Fabricators is a designer, manufacturer, and supplier of corrosion-resistant process equipment for industries facing corrosion challenges in Camarillo, USA. Their expertise lies in reactive metals and corrosion resistant alloys such as Titanium, Tantalum, Zirconium, and more. TITAN offers a wide range of process equipment, including Shell and Tube Heat Exchangers, Columns and Towers, Condensers, Reactors, and Pressure Vessels. The company serves diverse industries like Oil and Gas, Pharmaceutical, Steel, and Chemical. Their subsidiary in Wuxi, China, also specializes in Reactive Metal Process Industry Equipment.

-

-

-

-

-

Tempco Electric Heater Corp.

Pipe Fittings

Manufacturer Overview

Tempco is based in Wood Dale, Illinois and has been in business since 1972. Tempco is a manufacturer of many types of heating elements and thermocouples with design variations. Tempco is ISO 9001:2015 certified. Temco’s electric heaters and elements include band heaters, cartridge heaters, cast-in heaters, ceramic fiber heaters, coil and cable heaters, drum heaters, enclosure heaters, flexible heaters, heat trace cable, heated hose and tubing, infrared heaters, process heaters, shroud systems, strip heaters, tank heaters, and tubular heaters. Tempco also sells various application accessories and wiring accessories.

-

-

-

-

-

Anamet Electrical, Inc.

Fittings On Anamet Electrical, Inc.

Manufacturer Overview

Anamet Electrical Inc., established in 1908 and located in the United States, is a manufacturer and supplier specializing in quality electrical conduit systems for diverse applications. Anamet offers a comprehensive assortment of products, including flexible conduits, fittings, and accessories, meticulously designed to cater to diverse needs in commercial, industrial, and residential settings. These conduits play a pivotal role in safeguarding electrical wiring from various threats, including mechanical damage, moisture, and corrosive conditions.

-

-

-

-

-

Pyromation

Pipe Fittings

Manufacturer Overview

Pyromation began operations in 1962 and operates out of Fort Wayne, Indiana. Pyromation is a manufacturer of RTD temperature sensors, thermocouples, and thermowells. Pyromation serves the aerospace, aggregate, chemical, energy and power, food and beverage, heat treating, HVAC, incineration, medical, metal processing, mining, oil and gas, pharmaceutical, plastics, rubber, and waste/water industries. Pyromation’s product lines include thermocouples, RTDs, thermowells, transmitters, connection heads, wire, and accessories. Pyromation also offers application assistance, calibration, training, and custom design services.

-

-

-

-

-

Eldon James Corp.

Pipe Fittings

Manufacturer Overview

Eldon James Corporation was founded in 1987 and is headquartered in Denver, Colorado. Eldon James is a manufacturer of specialized connectors and tubing for global markets. Eldon James' product categories include quick disconnects, bag ports, 3D filaments, various adapters, fittings, and accessories. Eldon James also offers an online resource toolbox including an extensive library, literature, infographics, and videos. Eldon James has capabilities in laser clamp welding technology, and green manufacturing including PVC-free assemblies, and thermoformed custom tubing.

-

-

-

-

-

Thermocouple Technology, LLC

Pipe Fittings

Manufacturer Overview

Thermocouple Technology, LLC. was founded and headquartered in Quakertown, Pennsylvania. The company manufactures a full line of temperature measurement products, including thermocouples, RTDs, and related products and accessories for industries including power generation, pharmaceutical, aerospace, and semiconductor manufacturing. In addition to thermocouples and RTDs, the company’s product line includes thermowell, thermocouple wire & accessories, transmitters, and indicators. The company offers custom manufacturing in multiple material types for both large and small orders upon customer request.

-

-

-

-

-

International Polymer Solutions, (iPolymer)

PTFE Fittings & Connectors

Manufacturer Overview

International Polymer Solutions (iPolymer) is headquartered in Irvine, California. iPolymer is a manufacturer of high purity fluid valves, cylinders, and related arts used in semiconductor, biomedical, pharmaceutical, food and sanitary processes, high-purity laboratory, and other general chemical handling environments. iPolymer’s product categories include PTFE fittings & connectors, PTFE spray guns & devices, solenoid valves, pneumatic valves, manual valves, other flow devices, air cylinders, and custom polymer fabrication and assembly. Custom fabrication includes custom plastic fabrication, precision CNC machining of plastics, custom fluid control products, and contract assembly services.

-

-

-

-

-

Colonial Engineering, Inc.

Pipe Fittings

Manufacturer Overview

Colonial Engineering, Inc. was founded in 1972 and is headquartered in Portage, Michigan. The company is a manufacturer of CNC, injection-molding, and other assembly and sub-assembly components for such industries as water treatment, automotive, HVAC, and industrial OEM. The company’s custom injection molding processes include molding, assembly, and fabrication using numerous materials such as PVC, Acetel, Nylon, Santoprene, and related thermoplastic polymers. The companys standard product lines include plastic valves, valve actuation devices, thermoplastic gear driven valves, unions, and butterfly valves.

-

-

-

-

-

Kenmold North America

Pipe Fittings

Manufacturer Overview

Kenmold North America (KNA) is an American contract manufacturer specializing in injection molding and tooling that was established in 1998 as a subsidiary of Kenmold China. Based in Bowling Green, Kentucky, the company offers various molding fabrication capabilities, including gas-assist, MUD and 2-shot mold tooling, as well as injection molding using onsite presses ranging from 25T to 1250T. It also offers printing, painting, coating, and plating services to add color, finishes or protective layers to produced plastic parts or molds. KNA chiefly serves clients in the medical, home appliances, automotive, and consumer electronics industries.

-

-

-

-

-

Plastic Design, Inc.

Pipe Fittings

Manufacturer Overview

Plastic Design, Inc. was founded in 1976 and is based in North Chelmsford, Massachusetts. The company is a manufacturer of equipment commonly used in industries such as biomedical, pharmaceutical, microelectronics, and photonics. The company achieved ISO 9001:2015 certification in 2018. The company’s products include wet process equipment, industrial systems, life sciences machinery, clean room storage, and more. The company also offers precision welding and machining services as well as plastic welding services for CNC plastic machined parts.

-

-

-

-

-

Wyandotte Industries, Inc.

Pipe Fittings

Manufacturer Overview

Wyandotte Industries, Inc., established in 1959, and headquartered in Wyandotte, Minnesota, is a manufacturer and supplier of slotted nuts. Their product range includes special nuts, nylon insert locknuts, and CNC machining. Their products support strength, functionality, and performance of diverse industrial applications, providing essential components, catering to various industries including automotive, aerospace, electronics, and consumer goods. These products find applications in structural, electrical, and mechanical systems. Wyandotte Industries hold certifications such as ISO 9001, adhering to industry standards.

-

-

-

-

-

U.S. Titanium Industry Inc.

Pipe Fittings

Manufacturer Overview

U.S. Titanium Industry Inc. is based in Monrovia, California, and is a manufacturer and supplier of titanium & titanium alloy, and metals such as zirconium, tantalum, niobium, and hafnium that have applications in various industries. The company provides titanium welding tubes&pipes, tube sheets, explode titanium clad steel plates, and, titanium bar&rod that have applications in pressure vessels, seawater desalination, heat exchangers, the petrochemical industry, and, pharmacy markets. They offer services including fabrication, forging, exportation, and metal processing that are needed in Mining, Oil&Gas, Aerospace, Construction, and, Automotive industries.

-

-

-

-

-

Morris Coupling Co.

Pipe Fittings

Manufacturer Overview

Morris Coupling is a family-owned company that was founded in 1941 and is headquartered in Erie, Pennsylvania. Morris is a manufacturer of compression coupling and components for pneumatic conveying and industrial vacuum systems. Morris Coupling has additional manufacturing facilities in Tennessee and Georgia, as well as distribution centers in Mexico, Europe, and Asia for international customers. Morris Coupling 7 product lines include couplings, flex hose, bends, and installation components. Most products are available in multiple configurations.

-

-

-

-

-

Universal Outlets, Inc.

Pipe Fittings

Manufacturer Overview

Universal Outlets, Inc. is a custom manufacturer of pipe fittings and other specialty items that was established in 1993. Based in Kilgore, Texas, the company offers various pipe fittings in a range of sizes including machined branchettes, specialty fittings, couplings, and studding outlets made to customer specifications. Its material selection includes stainless steel, chrome-molybdenum, titanium, brass, and other alloys. Universal Outlets products primarily serve clients in the industrial manufacturing, power generation, chemical processing, and mining industries.

-

-

-

-

-

OMEGA Engineering inc.

Tube fitting

Manufacturer Overview

OMEGA Engineering was originally begun in 1962 as a manufacturer of thermocouples and has grown to over 100,000 products for measurement and control of temperature, humidity, pressure, strain force, flow, level pH, and conductivity as well as customer service including data acquisition, electric heating, and custom-engineered products. Additionally, OMEGA offers tools to serve as reference for engineers around the world. OMEGA Engineering serves the aerospace, automotive, wireless, sanitary, test & measurement, process control, power monitoring, environmental, and laboratory markets.

-

-

-

-

-

Deublin Company

Rotating union

Manufacturer Overview

Deublin, established in 1945, is a manufacturer of rotating unions and fluid sealing systems, headquartered in Waukegan, Illinois, USA. Their products include rotary joints to facilitate fluid transfer between stationary and rotating components, steam joints for handling high-temperature steam transfer, and siphon systems for enabling fluid movement through gravity or pressure differentials. These products are used in various industries such as printing, packaging, steel, plastics, and food processing. Deublin is certified with ISO 9001 for quality management and ISO 14001 for environmental management.

-

-

-

-

-

Clippard

Miniature pneumatic fitting

Manufacturer Overview

Clippard Instrument Laboratory, Inc. was founded in 1941 in Arkansas and is now located in Cincinnati, Ohio. The company is a manufacturer of miniature pneumatic valves, specializing in ultra low leak, precision pressure control, and high-resolution flow control. Categories of Clipard Products include electronic valves, proportional valves, isolation valves, electronic controls, custom solutions, ppressure regulators, control valves, directional control valves, air pilot valves, air preparation equipment, and fittings hose, and tubings.

-

-

-

-

-

East Bay Distributors Inc.

Industrial Pipe Fittings Archives

Company Overview

East Bay Distributors, Inc. is a distributor for pneumatic applications, specializing in connectors, fittings, and industrial parts used across industries by both small companies and Fortune 500 corporations. The company’s distribution categories include SPC Fittings, SPC Products, Brass Fittings & Adapters, and Accessories. The company also features Dewalt protective products, including eyewear and work gloves. The company’s inventory management systems for customers offers benefits of lowering inventory costs, improving cash flow, and savings customers time and resources.

-

-

-

-

-

Potter Associates, Inc.

STAINLESS STEEL TUBING, FITTINGS & VALVES

Company Overview

Potter Associates, Inc. was founded in 1964 and is based in Rochester, New York. Potter Associates is a manufacturer and distributor industrial materials, tools, and machinery. Manufacturing capabilities include V packaging sets, O-rings, gaskets, sheet material, rubber extrusions & sheet material, heat exchangers, compression braided packing, non-asbestos brake linings, urethane molding, and PTFE machining. Other product offerings include valve packing, pulp and paper packing, soot blower sets, copper packing, metallic packing, and wastewater treatment packing.

-

-

-

-

-

Steel & O'Brien Manufacturing

Pipe Fittings

Company Overview

Steel & O’Brien was founded in 1990 and operates out of Arcade, New York. Steel & O’Brien is a distributor of standard and custom-machined/fabricated fittings and assemblies. Steel & O’Brien serves the food, dairy, beverage, brewery, winery, distilling, biotechnology, pharmaceutical, cosmetic, personal care, extraction, semiconductor, and water treatment industries. Steel & O’Brien offers a range of products including various fittings, valves, actuators, diaphragm valves, pumps, accessories, sight glasses, strainers, filters, tubing, hangers, and others.

-

-

-

-

-

RapidAir Compressed Air Products

Brass Fittings

Company Overview

RapidAir Compressed Air Products (RapidAir) is headquartered in Auburndale, Wisconsin. RapidAir is a manufacturer and distributor of compressed air piping systems. RapidAir’s store sells premade systems and also offers custom-design assistance for customers to design their own systems. RapidAir’s sore includes Fastpipe brand aluminum pipes as well as clips, elbows, and other components; Maxine tubing, clamps, and fittings; beveling tools, fittings, valves, pipe cutters, as well as numerous other accessories and master kits.

-

-

-

-

-

Sterlco Sterling Authorized Dist. - M & M Control

Pipe Fittings

Company Overview

Sterling Sterlco was founded in 1916 and distributes under M&M Control Service, Inc. is a specialist in industrial control units. Industrial control units are in two basic varieties: steam control family and temperature control units. Steam Control units include steam traps, Y strainers, temperature control valves, hand radiator valves, boiler feed pumps, condensate pumps, and centrifugal pumps. Temperature control units include portable chillers, central chillers, and water and oil temperature control units. Additionally, Sterling also manufactures pump tanks.

-

-

-

-

-

Seal Fast, Inc.

All Categories

Company Overview

Seal Fast, Inc. was founded in 1933 and is headquartered in Houston, Texas. Seal Fast is a distributor of sealing and fitting products. Seal Fast product categories include couplings, fire protection, gauges, pipe fittings and valves, hose and hose protection, and sheet rubber. Couplings include cam and groove, dry disconnect, shank, ring lock, foot valves, brass fittings, hydraulics, clamps, and banjo couplings. Fire protection equipment also includes gaskets, and industrial ground monitors. Gauges include siphons, oxygen, and thermowells. Pipe fittings and valves include combination nipples and flanges. Hose and hose protection include Fire hoses and industrial rubber. Sheet rubber includes skirt board and cloth insert neoprene.

-

-

-

-

-

Metalloy

Pipe Fittings

Company Overview

Metalloy was founded in 1969 and is based in St. Charles, Illinois. Metalloy is a distributor of industrial and construction supplies. Metalloy offers tube & pipe products, PVF, die sets & plates, die & mold tooling, general tooling, steel storage, and SK hand tools. Tube & tube products include mechanical tubing, stainless steel tubing, and piping. PVF includes piping, fittings, flanges, valves, studded outlets, and machined rings. Die sets & plates include parallels, risers, and steel tools. Die & mold tooling include die punches, die buttons, drill busings, and mold components.

-

-

-

-

-

G.A. Murdock, Inc.

Pipe Fittings

Company Overview

G.A. Murdock was founded in 1992 and is based in Madison, South Dakota. The company is both a manufacturer and a distributor of the valve, fitting, and filters to customers around the world. Brands the company carries include Aquate, HM Digital, Relton, and Tomlinson. Through its in-house production, the company molds, extrudes and assembles molding products and turnkey custom plastics manufacturing services under the Mur-lok brand. The company’s other product line offerings include chemicals, instruments, pressure gauges, and tools.

-

-

-

-

-

Paramount Fasteners Inc.

Pipe Fittings

Company Overview

Paramount Fasteners was founded in 1988 and is based in Santa Fe Springs, California. Paramount Fasteners supplies both common and rare industry standard nuts, bolts, screws, and other fastener products. Materials that Paramount Fasteners uses include B16, B8, B8M, B16, B7, 16-4, 17-7, Inconel, Hasteloy, and Monel and provided in 300 series stainless steel, 316 stainless steel, brass, bronze, carbon steel, nylon, and plastic. Paramount Fasters also distributes parts that have painted heads, hot dip galvanized, zinc plated, cad plated, black oxided, chrome plated, and flour coated.

-

-

-

-

-

Colonial Teltek

Pipe Fittings

Company Overview

Colonial TelTek was founded in 1972 and operates in King of Prussia, Pennsylvania. Colonial TelTek is a division of Colonial Electric Supplies. Colonial TelTek primarily serves the telecommunications and utility industries as a parts distributor and emergency service provider. Colonial TelTek is offers 8 major product lines including aerial hardware components, bridge conduit systems and conduit accessories, fiber optic cable and splice accessories, handholes and racking products, pulling products, PVC, HDPE, and fiberglass conduit, as well as tools and accessories.

-

-

-

-

-

Metro Hydraulic

Pipe Fittings

Company Overview

Metro Hydraulic Jack Co. is a third-generation family run business in operation since 1941. MHJ is based in Newark, NJ. MHJ distributes hydraulic jack-related equipment, tools, and parts including a broad range of cylinders, motors, valves, presses, couplings, tools, hydraulic fittings, hoses, jacks, pumps, lifts, lubrication equipment, pallet stackers, scissor lifts, and workholding devices. MHJ also offers system design services as well as engineering services and extensive repair including testing, retrofitting, and overhauling.

-

-

-

-

-

Engineered Source, Inc.

Pipe Fittings

Company Overview

Engineered Source Inc was founded in 1990 and operates out of Orange, California. Engineered Source Inc is a distributor of precision parts for numerous industries including automotive manufacturers, construction, electronics & robotics, fabrication & assembly, farm & agricultural equipment, gun manufacturers, marine & water treatment, medical manufacturers, and aerospace. Examples of specific products include custom internally threaded square pins, stainless steel pins, steel hex nuts, short dog point socket set screws, zinc plated steel material, custom stamped L brackets, painted self-drilling screws, and custom-locating dowel pins for transit gear units.

-

-

-

-

-

Industrial Specialties Mfg., Inc.

Pipe Fittings

Company Overview

Industrial Specialties Manufacturing (ISM) was founded in 1982 in Denver Colorado. is an ISO 9001 company that supplies miniature pneumatic, vacuum, and fluid circuitry components to OEMs and distributors all over the world as well as providing custom solutions. The company serves distributors and offers not just sales but also marketing and logistics support with closed-loop feedback. Some of the types of products ISM offers include plastic fittings, customized fittings, sub-assemblies, and custom heat seal tooling.

-

-

-

-

-

SC Fastening Systems

Pipe Fittings On SC Fastening Systems

Company Overview

SC Fastening Systems hailing from Macedonia, OH is an industrial and construction supply distributer that provides value-added services. Product lines include fasteners, concrete anchors, abrasives, cutting tools, safety, janitorial, welding, paints and chemicals, material handling, tools and equipment, electrical, hydraulics and pneumatics, and lifting and rigging. Additionally, SC Fastening Systems offers specialty parts for niche industries such as laundry chute parts and custom hinges. SC Fastening Systems also offers services including inventory management and supply chain solutions, modified parts, kitting, assembly and special packaging, and fire protection products and services.

-

-

-

-

-

Petersen Products Co.

Pipe Fittings & Adapters for Pipe Plugs and Packers

Company Overview

Peterson Products Company is based in Fredonia, Wisconsin and has a history dating back to its first patent issued in 1916. Peterson Products Company is ISO 9001:2015 certified manufacturer and distributor of products designed to assist customers with wastewater, tunneling, plumbing, and pipeline needs. Peterson’s product categories include annular seals, contractor tools, custom inflatable tools, custom manufacturing, inflation accessories and fittings, lifting bags and pipe handlers, pecker carriers, high pressure pipe plugs, chemical resistant pipe plugs, temperature and pressure gauges, and test equipment.

-

-

-

-

-

MAXPRO Technologies, Inc.

High Pressure Fittings On MAXPRO Technologies, Inc.

Company Overview

MAXPRO Technologies was founded in 195 and is founded in Fairview, Pennsylvania. MAXPRO is a distributor for pumping products including air driven liquid pumps, gas boosters, air amplifiers, high-pressure valves, fittings, and tubing. Other products include high-pressure fittings such as adapters, bulkheads, couplings, crosses, elbows, nipples, and tees. Rental equipment and complete systems such as air amplifier systems, liquid pumping systems, gas booster systems, oxygen gas booster packages, portable test carts, high pressure test systems and custom systems are also available.

-

-

-

-

-

Gibson Stainless & Specialty, Inc.

Pipe Fittings

Company Overview

Gibson Stainless was founded in 1995 and is headquartered in Greensburg, Pennsylvania. The company is a distributor of electrical fittings, and complete conduit systems in Type 316 SS for industries such as food & beverage, marine, infrastructure, chemical processing, and wastewater treatment and attempts to source as many components as possible from the United States from domestic manufacturers. Most of the company’s product offerings are stainless steel. Product categories include hubs, connectors, clamps, conduit components, anchors, and other fittings.

-

-

-

-

-

U.S. Rubber Supply Co.

Pipe Fittings

Company Overview

US Rubber Supply Company is headquartered in Brooklyn, New York. The company is a manufacturer and stocking distributor of standard and custom rubber goods and other services for OEM, military, and various commercial industries. The company’s product lineup includes bumpers & fenders, expansion joints, hose & fittings, snow plow blades, and window products. The company offers complete die-cutting and molding extruding services and offers custom fabrication capabilities to customer specifications. Just-in-time delivery on all rubber goods is also available.

-

-

-

-

-

Main Mfg. Products

Pipe Fittings

Company Overview

Main Mfg. Products, established in Michigan, in 1955, is a manufacturer and distributor of hydraulic flanges. Their product range includes a range of flanges in various sizes and pressure ratings to accommodate diverse hydraulic system configurations, Flange Adapters, Sturdy clamps, designed to secure hydraulic flanges and prevent leaks and sealing solutions. The company serves industries such as Oil and Gas, Aerospace and Defense, Automotive and Transportation, Construction, and Power Generation.

-

-

-

-

-

Western States Hardware

Pipe Fittings

Company Overview

Western States Hardware was founded in La Puente, California in 1968. Western States Hardware serves customers across the United States, offering products in a number of categories including: nuts, screws, & bolts, metric nuts, screws, & bolts, drills & cutting tools, saw blades, electrical connectors, pipe nipples, & pipe fittings, industrial brushes, parker brass fittings & valves, anchors, abrasive pads, belts, & discs, chain & rigging accessories, various tools, valves, staple & nail guns, power & insert bits, and hoses, tubing, & clamps. Altogether, Western States Hardware offers over 750,000 products available.

-

-

-

-

-

Associated Fastening Products, Inc.

Brass Fittings

Company Overview

Associated Fastening Products, Inc. (AFP) was established in the early 1990s in Itasca, Illinois. AFP is a manufacturer and distributor of both standard and special fasteners for all uses, with many customers in the agriculture and gun manufacturing industries. Some of AFP’s product and service offerings include automatic screw machining, CNC services, brass fittings, standard fasteners, CNC machining, laser and waterjet cutting services, custom cold headed fasteners, metal stamping services, standard and special washers, cable ties, hardware kits and bagging, Swiss screw machining, inventory management, large diameter bolts, security fasteners, and wire form products.

-

-

-

-

-

-

-

Pro Flow Dynamics, LLC

Camlock Fittings

Distributor Overview

Pro Flow Dynamics, LLC is a supplier of camlock fittings & couplings, stainless steel hose fittings & steel ball valves, and brew hardware. The company is founded in 2007 and is established in Corona, United States. The company initially started selling camlock fittings from their Californian base and then expanded into supplying a full range of brewery and home brew fittings and hardware. The company all industries like: manufacturing, oil & gas, home brew, pharmaceutical, chemical, municipal, agricultural, food & beverage, hygienic and general industries.

-

-

-

-

-

B & S Aircraft Alloys, Inc.

Pipe Fittings

Distributor Overview

B & S Aircraft Alloys was founded in 1979 and headquartered in Syosset, New York. The company is a distributor of precision parts and titanium, nickel, aluminum, stainless, and commercial alloys to customers in the aerospace as well as medical, scientific, petrochemical, and industrial industries across the United States. The company meets with certifications for military and other specifications and supplies customers such as Boeing, NASA, Honeywell, and General Motors. The company provides parts and service for several aircraft including commercial 737s and military F-15s.

-

-

-

-

-

Maxpro South, Inc.

Pipe Fittings

Distributor Overview

MaxPro South, Inc. was founded in 2000 and is based in Humble, Texas. MaxPro South is a stocking distributor of liquid pumps, gas boosters, air amplifiers, valves, fittings, and tubing. MaxPro South specializes in MAXIMATOR brand products. Rental equipment including coning and threading machines, hydrostatic testing equipment, and gas booster equipment is also available. MaxPro South uses factory-certified parts to repair and condition liquid pumps, gas boosters, air amplifiers, and valves. MaxPro South also offers on-site installation of custom systems including coning, threading, and bending of tubing. Service contracts are also available.

-

-

-

-

-

Superior Industrial Supply

Hose & Fittings

Distributor Overview

Superior Industrial Supply was founded in 1969 and is headquartered in Saint Louis, Missouri. Superior Industrial Supply is an independent distributor of industrial supplies. Superior Industrial Supply has an inventory of over 20,000 products as well as hundreds of thousands of non-inventory products usually available within 24 hours. Superior Industrial Supply products include fasteners, hose, fittings, electrical supplies, abrasives, brushes, other tools, assorted paints, assorted chemicals, shop supplies, and services. Servies include hydraulic hose assemblies as well as vendor managed inventory services.

-

-

-

-

-

Macomber Cryogenics, Inc.

Pipe Fittings

Distributor Overview

Macomber Cryogenics was incorporated in 1978 and is based in Shrewsbury, Massachusetts. The company serves the industrial gas, cryogenic, high-tech, and biomedical industries as a supplier of gas and cryogenic supplies and equipment. The company’s two primary product lines are vacuum-insulated pipe and Cryo-Tube and cryogenic bulk tankage. The company also offers accessories such as control systems and valves for sale, as well as used equipment. The company’s service offerings include planning and installation of parts and systems as well as custom components.

-

-

-

-

-

Jamtek Enterprises, Inc.

Precision Hydraulic Grease Fittings On Jamtek Enterprises, Inc.

Distributor Overview

Jamtek Enterprises, Inc. (JE) is an American distributor of screw machine products and accessories founded in 1987 and based in Harrison, Ohio. The company stocks precision hydraulic grease fittings and brake parts, as well as lubrication equipment and industrial hydrostatic drives. It also offers bleeder screws, grease guns, brake pistons, and relief valves. JE primarily serves clients in the agricultural equipment, industrial machinery, automotive, and construction sectors, including New Holland Agriculture S.p.A. and Case Construction Equipment Inc.

-

-

-

-

-

M. Brown Fitting Specialists, Inc.

Grease Fittings

Distributor Overview

M. Brown Fitting Specialists Inc. was founded in 1930 and headquartered in Bogota, New Jersey. The ISO 9001-compliant company is a distributor of grease fitting and lubrication supply products from brands such as Alemite, Lincoln, Duralube, Balcrank, and Kingfisher. The company’s product listings include grease fittings other lubrication equipment, and other products. Grease fittings categories include brass, metric, leakproof, NAS grease fittings, and special thread designs. Other lubrication equipment includes adapters, bushings lock nuts, and pipes.

-

-

-

-

-

Midway Industrial Supply & Systems

Hose & Fittings

Distributor Overview

Midway Industrial Supply is based in Mounds View, Minnesota. Midway specializes in supplying industrial companies such as automotive, food & beverage, chemical, medical, pulp & paper, and OEMs with paint and powder application equipment and fluid management equipment. Some of Midway’s offerings include fluid pumping, transferring, dispensing, spraying equipment for paints, resins, adhesives, sealants, solvents, lubricants, inks, chemicals, foods, and sanitary products. Midway also offers services including repair, service, consulting, training, and technical information for customers.

-

-

-

-

-

M & M Rogness Equipment Co.

Tuthill Quick Couplings

Distributor Overview

M & M Rogness Equipment Company was founded in 1947 and headquartered in Roseville, Minnesota. M & M Rogness is an industry provider in the distribution, sales, and service of hydraulic and pneumatic products. M & M Rogness’s product line includes hundreds of parts including both components and full machines. Components include valves, cylinders, couplings, baskets, and other accessories. Additionally, machines such as filtration devices, power units, pumps, and motors are also available. M & M Rogness distributes both domestically and overseas and offers custom order accommodation for items not found in their catalog.

-

-

-

-

-

Central Diesel, Inc.

Pipe Fittings

Distributor Overview

Central Diesel, Inc was founded in 1972 by Martin R. Wittersheim and is located in Richmond, Virginia. Central Diesel is a distributor of marine, construction, mining, rental, industrial, military, state government, federal government, transportation, and agriculture industries. Central Diesel product categories include diesel engines, diesel engine electrical components, diesel engine filtration systems, diesel engine maintenance & repair, diesel engine turbocharger assemblies, diesel exhaust systems, fuel injection systems & parts, generators, and hydraulic hoses & fittings.

-

-

-

-

-

R.L. Craig Company, Inc.

Round Duct (Spiral & Snap Lock) & Fittings On R.L. Craig Company, Inc.

Distributor Overview

R.L. Craig Company, Inc. was founded in 1955 and is headquartered in Louisville, Kentucky. R.L. Craig Company is a distributor of HVAC and related products for residential, commercial, and industrial customers. R.L. Craig Company’s product lines include air distribution such as displacement ventilation and clean room exhaust systems, louvers and dampers such as fire & smoke dampers, vibration & noise control such as floating floor systems, duct systems such as acoustical duct, dust & filtration systems such as oil mist collectors, heating & cooling equipment such as gas unit heaters, fans such as utility set fans, and other equipment such as laboratory air flow controls.

-

-

-

-

-

Marcuse & Son, Inc.

Pipe Fittings

Distributor Overview

Marcuse & Son was established in 1925 and operates out of Fort Worth, Texas. Marcuse & Son is a distributor of air compressors and air compressor parts and accessories. Air compressor offerings include reciprocating air compressors and rotary style air compressors. Marcuse & Son’s accessories include air receivers, alternators, belt guards, block heaters, brass valves and fittings, breather vents, compressor lubricants, exhaust mufflers, filters, regulators & lubes, refrigerated air dryers, and water separators.

-

-

-

-

-

Circle Valve Technologies Inc.

Pipe Fittings

Distributor Overview

Circle Valve was founded in 1986 and headquartered in Harleysville, Pennsylvania. Circle Valve is a value-added distributor and manufacture rep of industrial valves, fittings, filters, and measurement control devices for a variety of industries and applications. Among Circle Valve’s product listings are check valves, relief valves, vacuum & high purity fittings, circle seal solenoid valves, Jefferson solenoid valves, Atkomatic solenoid valves GO regulators, cryogenic valves & equipment, hoke valves, Gyrolok Tube Fittings, Circle Seal Control Valves, and various measurement devices.

-

-

-

-

-

Liquidyne Process Technologies, Inc.

Pipe Fittings

Distributor Overview

Founded in 1993, Liquidyne Process Technologies serves the dairy, brewery, distillery, biotech, pharmaceutical, & cannabis industries. Liquidyne offers a full line of sanitary and single-use products including process equipment components, sanitary equipment, single-use pumps and valves, single-use fittings and connectors, custom single-use assemblies, sanitary hose assemblies, sanitary valves, and single-use bioprocessing systems. Liquedyne produces all equipment in an ISO14644 Class 7-certified cleanroom has also attained 9001:2015, USP Class VI Testing, ASME Bioprocessing Equipment, and EHEDG certification status. Liquedyne also offers process optimization and on-site process audit & evaluation services.

-

-

-

-

-

HydraCheck

Pipe Fittings

Distributor Overview

HydraCheck was established in 1990 and headquartered in West Valley City, Utah. The company is a distributor of diagnostic testing and maintenance for hydraulic systems across North America. The company provides support services for end customers as well as mechanics and technicians. The company’s product lines include testing products, diagnostic kits, and safety devices. Testing products include flanges, gauges, and thermometers while kits include identification kits and test kits. The company's safety devices include goggles, models, and guides.

-

-

-

-

-

Clean Air Company

Plymovent Stainless Steel Conical

Distributor Overview

Established in 1976, The Clean Air Company has been providing high-quality air purification services to manufacturing facilities, vehicle maintenance, and office space. Their main purpose is to improve indoor air quality by filtering or exhausting various pollutants that threaten employees' health. Known for their exceptional services, the clean air company has faithfully served Delaware, Pennsylvania, Connecticut, New York, and New Jersey, residents. In the pursuit of providing clean air, they have been helping businesses remain safe, lucrative, and compliant by reducing insurance, maintenance, and energy costs.

-

-

-

-

-

Orr & Orr, Inc.

M-2542, Intake Fitting On Orr & Orr, Inc.

Distributor Overview

Orr & Orr, Inc. has been offering wholesale distribution services since 1934 out of Bedford Park, IL. Orr & Orr emphasizes speed of order processing, shipping, and both customer and distributor satisfaction. Product categories that Orr & Orr offers include air conditioners, brake controls, cargo restraint equipment, door tracks, lighting equipment, fans, gas springs, heating equipment, hinges, plumbing supplies, seat belts, steps, toolboxes, hitch and towing products, various truck hardware, cables, battery products, safety equipment, and spring latches.

-

-

-

-

-

Sutton-Garten Co.

Pipe Fittings

Distributor Overview

Sutton Garten Co.’s history dates back to1916 in Indianapolis, Indiana. Sutton Garten is an independent welding distributor, providing products and services. Sutton Garten’s product offerings include welding abrasives, dry ice & blast equipment, electric welding equipment & supplies, filler metals, flux and chemicals, fume extraction equipment, gases, cylinders, dewars, gas equipment for welding, welding hand tools, plasma cutting equipment, metal cutting sawing grinding tools, welding safety equipment, and weld accessories. Sutton Garten’s service offerings include bulk gas installations, carbon dioxide gas fill service, rental welding & cutting equipment as well as repairs.

-

-

-

-

-

N.T. Ruddock Co.

Pipe Fittings

Distributor Overview

N.T. Ruddock Company was founded in 1951 and is located in Cleveland, Ohio. N. T. Ruddock is ISO 9001:2015 registered and is a distributor off industrial equipment. Product lines include blast cleaning abrasives, equipment and replacement parts, primary and secondary aluminum ingot, aluminum and copper master alloys, and pure metals. Abrasive options include glass beads, corn cob, crushed glass, steel shot, copper slag, and more. Metal options include aluminum alloys, aluminum master alloys, copper master alloys, ferro alloys, alloy additions, and beryllium alloys. Additionally, N.T. Ruddock also sells many types of parts such as nozzles, guns, and valves, in addition to larger equipment such as blast cabinets and blast pots. NT. Ruddock offers installation, cleaning, repair, custom bagging, and in-house blending of abrasives, and repair.

-

-

-

-

-

Aluminum Distributing, Inc.

Fittings, Flanges and Elbows

Distributor Overview

Aluminum Distributing, Inc. (ADI Metal) was established in 1958 in Fort Lauderdale, Florida where it is still headquartered today. ADI Metal is a distributor of metal and metallic materials for both private and public industrial and maritime industries both in the United States and abroad. ADI Metal is ISO 9001:2015 certified. ADI Metal’s product segments are split into aluminum alloy products, stainless steel products, and other ferrous and non-ferrous metals. These metals include armor plating, brass, bronze, carbon steel, copper, cupronickel, and titanium.

-

-

-

-

-

Ohio Pipe, Valve & Fittings, Inc.

Pipe Fittings

Distributor Overview

Ohio Pipe, Valves, & Fittings, Inc. was founded in 1929 as Ohio Pipe Bending & Coiling Company. Also known as the Ohio Pipe companies, they specialize in fully welded, seamless, stainless steel, and PVC pipes of many sizes. Ohio Pipe companies also sell flanges, couplings, ball, butterfly, gate, control, and relief valves, with thousands of unique items in stock. Ohio Pipe companies’ past and current customers include power plants, steel mills, oil and gas companies, chemical plants, water and wastewater facilities, as well as many OEMs.

-

-

-

-

-

-

-

Beartech Alloys, Inc.

Pipe Fittings

Distributor Overview

Beartech Alloys was founded in 1997 and is headquartered in Placentia, California. The company is an operated metal distributor and metal service center, focusing on specialty alloys such as stainless steel, nickel, bronze, and copper. The company stocks those alloys in bars, tubes, pipe, angles, sheets, and other shapes. The company also works with several mills, foundries, and other distributors to maximize the speed of service for customers. The company also provides heat treating, precision saw cutting, grinding, and polishing services.

-

-

-

-

-

Source Equipment Company, Inc.

Precision Screw Machining Services

Company Overview

Source Equipment Company, Inc. was established in 1989 and headquartered in Leominster, Massachusetts. Source Equipment Company is a solution provider in warehousing, distribution management, and equipment sourcing. Source Equipment Company’s extensive catalog includes bins, boxes, cabinets carts, casters, chairs, containers, conveyors, cranes, barriers, dollies, doors, dumpers, hoppers, lifting equipment, office furniture, pallets, partitions, platforms, racks, safety equipment, scales, security equipment, trucks, wires, work benches, and other warehouse equipment including access equipment such as stairlifts, wheelchair lifts, ramps and residential elevators.

-

-

-

-

-

COVAL S.A.S

Fittings

Manufacturer Overview

COVAL is a manufacturer of industrial vacuum components that was established in 1986 in Montélier, France. The company produces various vacuum technology products and related automation solutions. Its products include bell-shaped vacuum suction cups, vacuum grippers for precision material or workpiece handling operations, and spring compensators for adjusting height or positioning. It also offers custom vacuum systems for lifting, claming, and sealing operations for clients with unique projects. The company primarily serves customers in France’s automotive, industrial packaging, and aerospace sectors.

-

-

-

-

-

ERA CO.,LTD.

ELECTRIC CONDIUITS AND FITTINGS

Manufacturer Overview

Era Co. Ltd., established in 1983 and headquartered in Zhejiang, China, is a plastic pipe and piping system manufacturer, developer, and supplier. The company provides solutions for drainage, electrical conduits, and feedwater systems. The core products include PVC pressure pipes, CPVC fittings, and PVC insulating electrical pipes. These products find ideal use in various residential, commercial, and industrial water-piping systems and electrical systems. The company works with original equipment manufacturers and also provides private label toll manufacturing services. Its notable clients include The Home Depot, Hardware House, and Lowe's.

-

-

-

-

-

Zhejiang TOP Environmental Technology Co., Ltd

Plug

Manufacturer Overview

Zhejiang TOP Environmental Technology Co., Ltd., established in 2014 and headquartered in Zhejiang, China, is a manufacturer of industrial environmental protection and explosion-proof equipment. The company offers a wide range of products, including conveyor sieving, powder cleaning, dust free polishing type, floor grinding, and more. It also provides air circulation filtration, vacuum cleaner, and powder bin. Its industrial vacuum cleaner can extract liquids or slurry, which makes cleaning more efficient and productive. The company’s product are certified by ATEX, CE TUV Rhein, and CE DEKRA. It serves various industries such as petrochemical, aerospace, military, 3D printing, and more.

-

-

-

-

-

Formatura Iniezione Polimeri S.p.A.

FITTINGS

Manufacturer Overview