26 Clean Booth Manufacturers in 2024

This section provides an overview for clean booths as well as their applications and principles. Also, please take a look at the list of 26 clean booth manufacturers and their company rankings. Here are the top-ranked clean booth companies as of April, 2024: 1.CLEAN AIR TECHNOLOGY,INC., 2.Technical Air Products, 3.Ezad Lab Furnishing Inc..

Table of Contents

What Is a Clean Booth?

A clean booth is a space cleaning system that maintains a positive pressure in a simple space to prevent dust from entering from the outside.

Unlike a clean room, which requires strict control, a clean Booth is used in situations where a localized and simple space cleaning environment is required.

Uses of a Clean Booth

Clean rooms remove dust and other particles from the air at a microscopic level, while at the same time controlling temperature and humidity within a certain range. These performance requirements are standardized by ISO, making it an extremely advanced space cleaning system.

Clean booths, on the other hand, are used when a certain level of cleanliness is required locally, without the need to control the cleanliness of a large area of workspace. For example, they are used in semiconductor manufacturing plants, liquid crystal panel manufacturing plants, pharmaceutical manufacturing facilities, cosmetics manufacturing facilities, and food manufacturing plants.

Clean booths may also be used in conjunction with clean rooms when further improvement of the clean environment is required.

Principle of Clean Booths

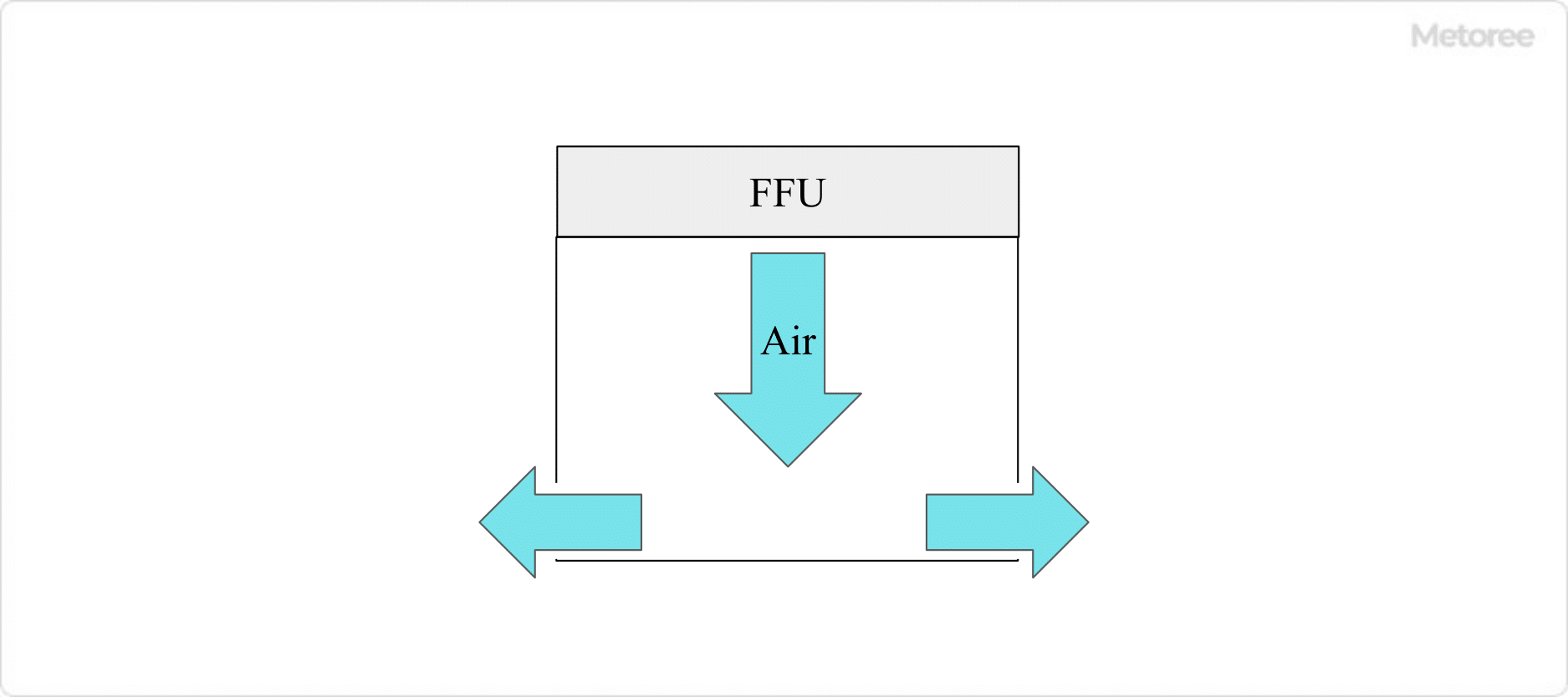

Figure1. Principle of a clean booth

In general, clean rooms, the space cleaning environment is strictly controlled using insulation panels to enable control of humidity and temperature, air conditioning, positive pressure equipment to enable room pressure setting, differential pressure damper, and other cleanliness equipment.

In contrast, a general clean booth is a small space composed of a frame, etc., covered with a polyvinyl chloride sheet or the like to shut off the space from the outside, and clean air is supplied by a fan filter unit (FFU) installed on the ceiling of the clean booth to maintain a clean environment. The pressure inside the clean booth is controlled by the FFU. The pressure inside the clean booth is maintained at a positive pressure by the FFU, preventing dust from entering from outside. Depending on the size of the clean booth to be installed, it is most important to select an FFU to maintain positive pressure in the interior space.

How to Use a Clean Booths

The following are points to be considered when using a clean booth.

It is essential to make sure that no dust, dirt, or microorganisms are brought into or generated in the clean booth. It is dangerous to rely solely on the performance of the clean booth. Rules and procedures for using the booth must be determined in advance, and the awareness of the users themselves must also be improved.

Cleaning of FFUs is also important. In particular, failure to clean the inlet port will reduce the cleanliness of the booth, so it is necessary to establish a procedure for periodic cleaning.

The clean booth is a simple system and has a gap at the bottom. Although the inside of the clean booth is controlled at a positive pressure, insects can still enter, and the floor around the clean booth should be kept clean on a regular basis.

The frequency and method of cleaning and the frequency of filter replacement will vary depending on the level of cleanliness required. It is necessary to consider in advance what kind of management is necessary according to the conditions of the environment in which the booth will be used.

Types of Clean Booths

1. Floor Type and Tabletop Type

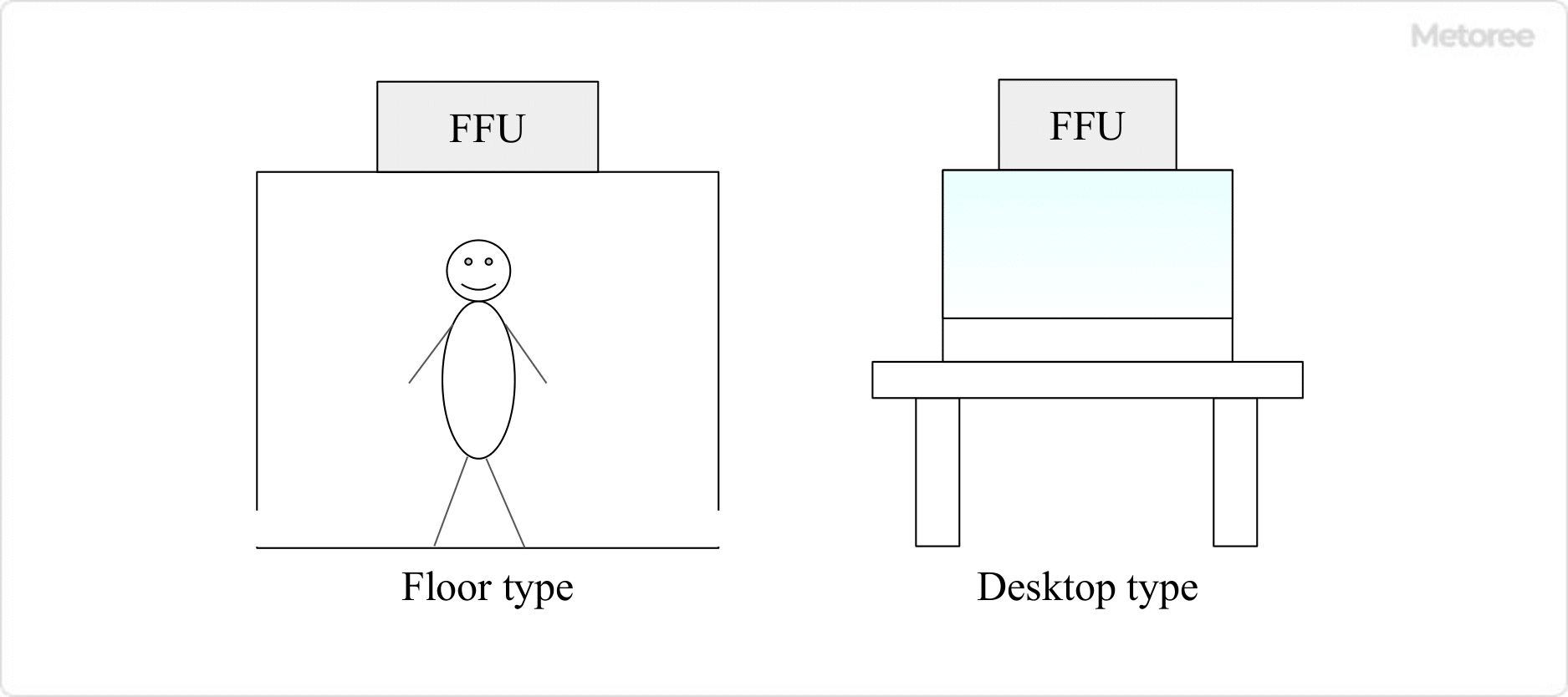

Figure2. Floor and desktop clean booths

The floor type is a large, clean booth installed on the floor and manned by people. They are used for large-scale work. In general, workers entering the booth must wear clean clothes to prevent foreign objects from entering the clean booth. Floor-type clean booth is mainly used in factories and other manufacturing sites.

Table-top clean booths are small clean booths installed on tables. Generally, only hands are allowed inside the clean booth, so workers do not need to wear clean clothes, making it easy to use. Tabletop clean booths are smaller and more compact than other types of clean booths, making them suitable for use in laboratories and factories with limited space. They are also generally easy to install and maintain and relatively inexpensive, so they are used by many companies and research institutes.

2. Closed Type and Open Type

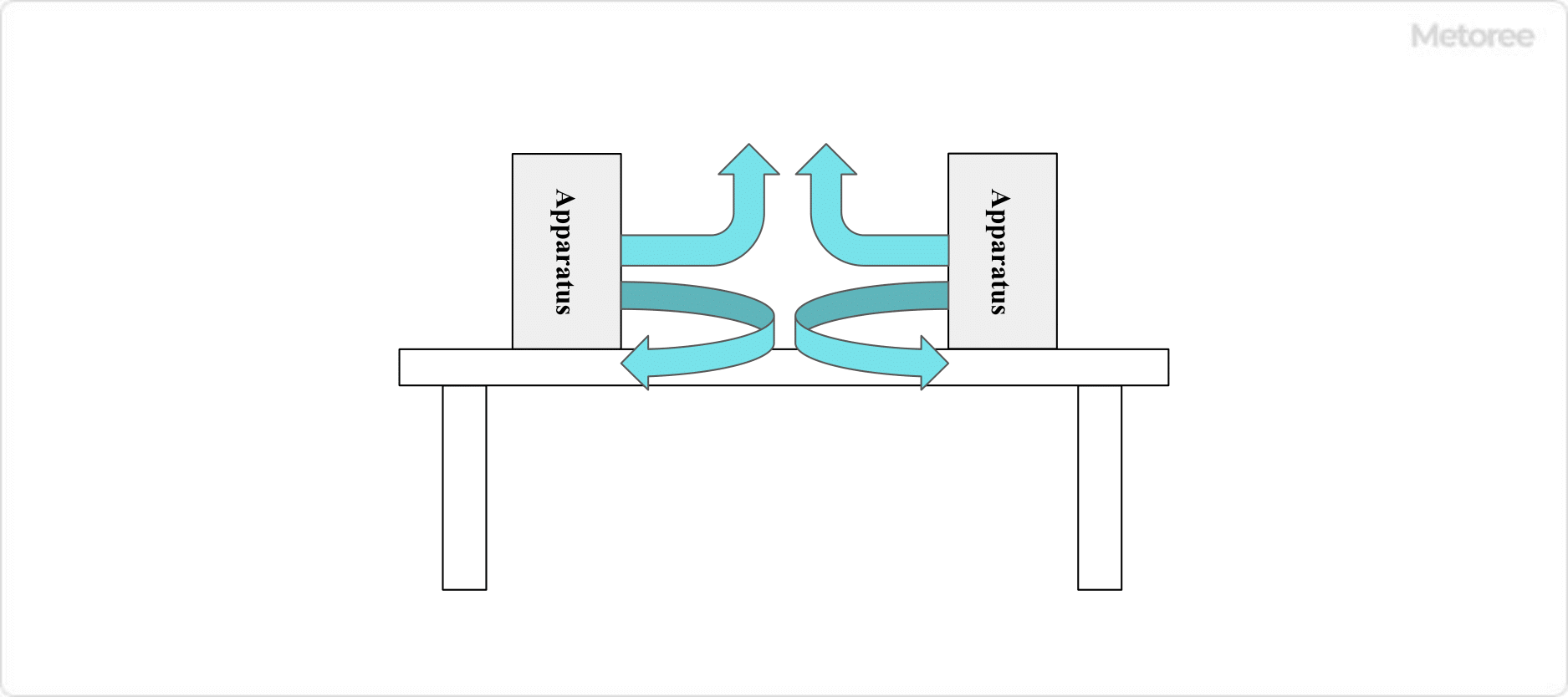

Figure3. Open-type clean booth

Closed-type clean booths, which create an enclosed space, are the most common type, but open-type clean booths are also available. An open-type Clean Booth is a type of equipment in which a constant flow of clean air is generated between pairs of airflow units, and work is performed in this space. Compared to closed-type clean booths, open-type clean booths are more portable and are used when a localized workspace needs to be kept in a highly clean environment at the Class 1 level.

3. Standard Type and Custom Type

Clean booth manufacturers sell clean booths of standard sizes and specifications, but they also accept customization from users. The standard type is available in a specified size at a lower cost than the custom type. Custom types can be made in any size desired, and various options can be added, such as adding an FFU anemometer.

Other Information on Clean Booths

1. Curtains for Clean Booths

There are various types of curtains for clean booths with different characteristics, which are selected according to the conditions of the environment in which they will be used.

The functions of curtains include fireproofing, insect repellency, antistatic, heat shielding, and light shielding. Curtains with antistatic functions are effective because static electricity creates an environment where dust and dirt can easily adhere.

2. Clean Booth With Aluminum Frame

Some clean booths are made with aluminum frames.

Advantages of using aluminum frames include the following:

- Lightweight

Aluminum is a very light metal, with a specific gravity of approximately 2.7 for aluminum and 7.8 for steel. Aluminum weighs about 1/3 of iron. - Manufacturing Costs and Time Can be Reduced.

Aluminum frames are often anodized on the surface. This reduces the number of processes, such as plating and painting, leading to cost and time savings. - Easy to Make Design Changes

Since aluminum is a soft metal, it is easier to process than other metals. It is also relatively easy to drill or cut holes later.

List of 26 Clean Booth Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- China

- Germany

- India

- Japan

- Taiwan

-

-

-

CLEAN AIR TECHNOLOGY,INC.

Modular Softwall Cleanrooms

Manufacturer Overview

CLEAN AIR TECHNOLOGY, INC.,established in 1982 and headquartered in Canton Town, Michigan, USA, is a manufacturer of advanced cleanroom, air purification, and filtration products. The product range includes air purifiers, filtration systems, and HVAC upgrades that offer improved indoor air quality, reducing pollutants, allergens, and contaminants. These products find application across industries such as healthcare, commercial, residential, and industrial sectors. By providing superior air purification systems, the company plays a crucial role in various industries, helping to improve the health, productivity, and well-being of building occupants.

-

-

-

-

-

Technical Air Products

SOFTWALL CLEANROOMS

Manufacturer Overview

Technical Air Products, founded in 1992 in Belmont, Michigan, USA, is a manufacturer of cleanroom products for various industries. The company manufactures a range of product varieties including modular cleanrooms, rigidwall cleanrooms, softwall cleanrooms, and pass-through chambers. These products offer controlled environments that ensure the optimum levels of cleanliness, particle control, and contamination prevention. The products find applications in industries such as pharmaceuticals, biotechnology, electronics, and healthcare, where stringent environmental control is necessary for research, manufacturing, and production processes. It delivers state-of-the-art cleanroom solutions tailored to the unique needs of its diverse clientele.

-

-

-

-

-

Clean Air Products

Softwall Cleanrooms

Manufacturer Overview

Clean Air Products, founded in 1969, is headquartered in Minneapolis, Minnesota, USA, and is a manufacturer of cleanroom solutions. The company's products include laminar flow hoods, modular cleanrooms, FFUs, pass-through chambers, air showers, softwall and hardwall cleanrooms, and workstations. It has received awards such as the prestigious Cleanroom Excellence Award in 2005 and holds certifications like ISO 9001 for quality management. Its products cater to a diverse clientele in critical industries like pharmaceuticals, electronics, aerospace, and healthcare.

-

-

-

-

-

-

-

SHIMIZU CORPORATION

Softwall Clean Rooms

Manufacturer Overview

SHIMIZU CORPORATION, a company founded in 1804 and headquartered in Chuo-ku, Tokyo, Japan, is a construction and engineering company. The company provides a wide range of construction services, including building construction, civil engineering, and environmental solutions. They also engage in delivering projects that adhere to stringent safety standards. Their services cater to various sectors such as commercial, residential, healthcare, and infrastructure. The company also offers customer services, including consultation, project planning, and post-construction support to meet clients’ requirements.

-

-

-

-

-

ACMAS Technologies Pvt. Ltd

Clean Booths

Manufacturer Overview

ACMAS Technologies Pvt. Ltd., headquartered in New Delhi, India, is a manufacturer and supplier of scientific, laboratory, and testing equipment. Its extensive product range includes spectrometers for chemical analysis, crucible furnaces for melting and heating, oscilloscopes for waveform visualization, data loggers for data recording, and an array of laboratory equipment like centrifuges, ovens, and balances which are utilized in academic, biotechnology, chemical, electronics, and food and beverage sectors. Apart from its regular equipment, customized scientific equipment as per the requirements and specifications provided are also available.

-

-

-

-

-

OLABO

Clean Booths

Manufacturer Overview

OLABO, established in 2012, is a manufacturer and supplier specializing in laboratory and scientific equipment based in Shandong, China. The company offers a wide range of laboratory equipment, including cleaning and disinfection equipment, safety protection products, medical equipment, and analytical tools. Their product portfolio also includes cold chain products and some industry research equipment. OLABO adheres to ISO13485, ISO9001, and CE certifications and maintains research, quality control, sales, and after-sales service teams to serve their clients across the globe.

-

-

-

-

-

BIOBASE GROUP

Clean Booths

Manufacturer Overview

BIOBASE GROUP is a Chinese manufacturer of medical and laboratory equipment founded in 1999 and headquartered in Jinan, Shandong. The company offers over 200 different products including laboratory and medical cryogenic equipment, clinical analytical instruments, air protection devices, and specialized storage products. It also produces various medical consumables such as gloves, masks, and syringes. Biobase Group has branches in the US, India, Dubai, Singapore, and Kazakhstan. It offers global distribution and additional customization services to its clients in the biotechnology, environmental, cosmetic, and educational sectors.

-

-

-

-

-

Guangzhou KLC Cleantech Co., Ltd.

Clean Booths

Manufacturer Overview

Guangzhou KLC, established in 1994, is an ISO 9001 certified manufacturer of air filters that is based in Guangdong, China. The company's products include vertical flow, three sides stainless steel, automatic roller door cargo and custom designed air showers. The products are used in area treatment in biopharmaceutical, semiconductor, livestock, power plants and HVAC systems industries. In 2006, the company became the first in China to pass the ISO certification of environment management and also won the National Quality Credit Enterprise in the same year. It has partnered with businesses and exports its products to Asia, Europe and America.

-

-

-

-

-

HOZAN TOOL INDUSTRIAL CO., LTD.

CL-903 CLEAN BOOTH

Manufacturer Overview

HOZAN TOOL INDUSTRIAL CO., LTD., established in 1946 in Naniwa-ku, Osaka, Japan, is a manufacturer and supplier of electronics and bicycle tools. Their product range includes soldering irons for electronics assembly, various types of multimeters for electrical measurements, pliers for wire manipulation, diverse screwdrivers for fastening tasks, and wire strippers for precise wire preparation. Additionally, they also offer chemical products such as anti-rust oils, freezer sprays, cutting oil, and dusters.

-

-

-

-

-

ORION MACHINERY Co., LTD.

Clean booth ⁄ FFU

Manufacturer Overview

ORION Machinery Co., LTD was founded in Nagano, Japan in 1946. ORION’s product line features precision air processors, vacuum pumps, chillers, dehumidifiers, air dryers, temperature test chambers, infrared and space heaters, temperature regulators, and automated milking equipment for dairy farming.

-

-

-

-

-

AIRTECH JAPAN,LTD.

Clean booth ⁄ FFU

Manufacturer Overview

AIRTECH JAPAN, LTD. established in 1973, and headquartered in Tokyo, Japan, is a manufacturer and distributor of total clean air systems and related equipment. The company's product range includes cleanroom facilities, BSL-3 labs, Air showers such as AAS (Advanced Pulse-jet air shower), Pass boxes like HPB (High-grade pass box), and clean benches. Serving industries like pharmaceuticals, biotechnology, advanced manufacturing, and medical research, these offerings ensure contaminant-free environments. Its services include design, manufacturing, sales products, and continuous research and development.

-

-

-

-

-

Micro Air Clean Air Systems

Cab Clean Air Booths

Manufacturer Overview

Micro Air Clean Air Systems was founded in 1969 and is a manufacturer of dust collectors and industrial air cleaners based in Wichita, Kansas, United States. The company manufactures various equipments such as ambient air cleaning systems, soource capture exhauster arms, and portable air cleaners. These products are used in various applications such as laser cutting applications, thermal spray, and wood working. The company has participated in various conventions and exhibitions such as FABTECH 2022 Atlanta and FABTECH 2020 Las Vegas.

-

-

-

-

-

Dynamic Engineering

JetBlack Standard Personnel Cleaning Booth

Manufacturer Overview

Dynamic Engineering has been a ventilation system manufacturer in Australia since 2002. The company provides solutions in the fields of ventilation, fume and dust extraction, air drying, and related services. Its range of ventilation systems includes HVAC fans, centrifugal fans, high-pressure fans, and high-temperature fans. as well as the UNI 2.2, a portable welding fume extraction system designed for the safety and well-being of workers exposed to welding fumes in various industrial settings. The company offers various customer support services, including replacement parts, technical manuals, and comprehensive service warranty support for its product line.

-

-

-

-

-

Shanghai Sunnyda Industry Co. Ltd.

Clean Booths

Company Overview

Shanghai Sunnyda Industry Co. Ltd., established in 2012 and based in Shanghai, China, is a manufacturer and supplier of cleanrooms and cleanroom equipment. The company's product portfolio includes cleanrooms, cleanroom panels, cleanroom doors, cleanroom windows, and cleanroom equipment. These products find applications in various industries, including pharmaceuticals, biotechnology, electronics, semiconductor manufacturing, as well as optics and photonics. The company holds both ISO 9001 and ISO 14001 certificates, and it exports its products to Norway, the United States, Canada, Belgium, and many South American countries.

-

-

-

-

-

-

-

OHM ELECTRIC CO., LTD

CLEAN BOOTH SYSTEM

Company Overview

OHM ELECTRIC CO., LTD, founded in 1961 and headquartered in Hamamatsu, Japan, is a manufacturer specializing in wiring accessories, as well as temperature and environmental control devices. OHM offers various wiring accessories including cable glands, insulation caps, and junction boxes. To meet the requirements for maintaining a clean work environment, especially in manufacturing sites, the company provides a range of coolers, dehumidifiers, and condensate evaporators for indoor temperature and humidity control, as well as oil mist and dust collectors. Moreover, OHM offers system integrations with regard to electrical engineering solutions and automated machinery for various industries, including medical, food, and robotics.

-

-

-

-

-

Sun Platec

Hood

Company Overview

Sun Platec is an ISO 9001-certified manufacturer and distributor of laboratory equipment and supplies that was established in Osaka, Japan, in 1960. The company offers laboratory equipment such as tubes and pipettes, and laboratory supplies such as wipes and tips. It also offers various containers including flasks and bottles, and polytetrafluoroethylene (PTFE) beakers and crucibles. The company’s products are commonly used in Asia’s educational and research institutions. Its clients include companies in the biotech, pharmaceutical, and food processing industries.

-

-

-

-

-

-

-

-

-

-

-

-

-

Changsha Eawayfilter Equipment Co., Ltd.

Softwall Clean Booth

-

-

-

-

-

Biobase Biodusty, Co., Ltd.

Clean Booth(Down Flow Booth)

Company Overview

BIOBASE, established in 1999, is a high-tech manufacturing enterprise whose business covers biomedical, e-commerce, intelligent manufacturing, scientific equipment In Vitro Diagnosis (IVD) instrument and reagent based in China. Specialized in research, development, and manufacturing of laboratory and medical equipment, catering to life sciences, healthcare, and environmental protection industries. Their product range includes biological safety cabinets, incubators, centrifuges, and more. The company has branch offices in 24 provinces in China, with overseas establishment in USA, Dubai, India, Algeria, Singapore, and business partners in 130 countries.

-

-

-

-

-

Air Clean Deviser Taiwan Corp.

Clean Booths

Distributor Overview

Air Clean Deviser Taiwan Corp., in China in 1993, is a supplier of cleanroom equipment. The company's product portfolio includes fan filter units, air showers, pass boxes, clean booths, and clean hand washers. Its products are used in healthcare facilities, including hospitals and laboratories, to maintain sterile environments for patient safety and research, development, and production in the pharmaceutical and biotechnology industries. It has more than 4,000 customers and 36 certifications such as UL, CE, ISO 9001, ISO 13485, and ISO 14001.

-

-

-

-

-

SLF Oberflächentechnik GmbH

CLEANING BOOTHS

Distributor Overview

SLF Oberflächentechnik GmbH was established in 1990 and is a supplier of surface treatment solutions based in Germany. The company provides flexible solutions for various aspects of surface treatment, including blasting systems, paint spraying systems, and conveyor technology. Its blasting systems include blast rooms and automated blast machines designed to blast larger serial components efficiently. Blasting is employed in various industries, including cleaning, surface preparation, and material removal. The company's international customer base includes companies in multiple industries, such as rail vehicle manufacturing, utility vehicle construction, wind power plants, and steel construction.

-

-

Clean Booth Manufacturer Ranking

*Including some distributors, etc.Ranking as of April 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | CLEAN AIR TECHNOLOGY,INC. |

21.1%

|

| 2 | Technical Air Products |

18.4%

|

| 3 | Ezad Lab Furnishing Inc. |

7.9%

|

| 4 | OLABO |

7.9%

|

| 5 | ACMAS Technologies Pvt. Ltd |

7.9%

|

| 6 | Clean Air Products |

5.3%

|

| 7 | Biobase Biodusty, Co., Ltd. |

5.3%

|

| 8 | SHIMIZU CORPORATION |

5.3%

|

| 9 | Alpha Clean Air Technology Co.,Ltd. |

2.6%

|

| 10 | Suzhou Super Clean Technology Co.,Ltd. |

2.6%

|

Derivation Method

The ranking is calculated based on the click share within the clean booth page as of April 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- ORION MACHINERY Co., LTD.: 251,233

- SHIMIZU CORPORATION: 19,869

- OLABO: 2,000

Newly Established Company

- Alpha Clean Air Technology Co.,Ltd.: 2015 (9 years ago)

- OLABO: 2012 (12 years ago)

- Jinan Clean Room Door Business Trading Co. Ltd.: 2012 (12 years ago)

Company with a History

- ORION MACHINERY Co., LTD.: 1946 (78 years ago)

- HOZAN TOOL INDUSTRIAL CO., LTD.: 1946 (78 years ago)

- OHM ELECTRIC CO., LTD: 1959 (65 years ago)

Clean Booth Manufacturers in United States

*Including some distributors, etc.

Global Distribution of Clean Booth Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

Japan

Japan

|

7 | 33.3% |

China

China

|

7 | 33.3% |

United States of America

United States of America

|

4 | 19.0% |

India

India

|

1 | 4.8% |

Taiwan

Taiwan

|

1 | 4.8% |

Germany

Germany

|

1 | 4.8% |