50 FPC Manufacturers in 2024

This section provides an overview for fpcs as well as their applications and principles. Also, please take a look at the list of 50 fpc manufacturers and their company rankings. Here are the top-ranked fpc companies as of April, 2024: 1.Millennium Circuits Limited, 2.MADPCB, 3.King Epoxy Emblem Co., Ltd.

Table of Contents

What Is an FPC?

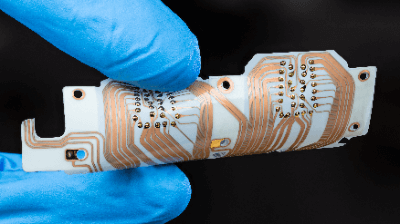

An FPC is a flexible printed circuit board. It is characterized by its paper-thinness and softness. Since it is lighter, smaller, and more economical than ordinary substrates, it has come to be widely used in recent years.

An FPC is a flexible printed circuit board. It is characterized by its paper-thinness and softness. Since it is lighter, smaller, and more economical than ordinary substrates, it has come to be widely used in recent years.

An FPC is also called flexible substrate, an acronym for Flexible Printed Circuits.

Uses of FPCs

FPCs are widely used in electrical appliances and consumer products. A typical application is smartphones. In most cases, FPCs are used in the control boards of smartphones. Because of their small size and lightweight, FPCs are useful for products that are carried daily.

In-home appliances, FPCs are used in LCD TVs. Since electronic control boards can be made smaller, they are economically advantageous. Other products include keyboards and printers, which have a wide range of uses. In addition, they are also used in heavy industry. In recent years, it has become a must-have component in the space development and aviation industries.

Principle of FPCs

The mechanism of an FPC is the same as that of a printed circuit board, but the biggest difference is that the base material is a film. Circuits are printed on insulating polyimide or polyester film with copper or other metals as wiring. Both the film and copper foil are about 12 µm to 50 µm, so they can remain quite thin even when laminated together.

FPCs are fabricated in the following manner.

- A thin copper foil is attached to a base film with an adhesive, such as epoxy resin.

- Dry film is coated on this base material for etching.

- UV light is irradiated to transfer the circuit diagram onto the dry film.

- The required portion of the circuit diagram remains on the dry film, and etching completes the circuit pattern on the copper foil.

- The dry film is peeled off, and an insulator film is applied to the entire surface for plating.

The above process completes lightweight and durable FPCs. there are two types of FPCs: single-sided FPCs and double-sided FPCs. While double-sided FPCs are less durable than single-sided FPCs, the advantage of double-sided FPCs is that they can be designed with higher density. In double-sided FPCs, the process of single-sided FPCs is repeated.

In recent years, FPC substrates with a flex-rigid structure and multilayered FPC substrates, in which a rigid substrate is sandwiched between FPCs, have also been developed. As a base material, polyimide is more heat-resistant and durable than polyester.

Other Information on FPCs

1. Characteristics of FPC

FPCs have three characteristics: high flexibility, lightweight, and high cost.

- High flexibility

Plastic films such as polyimide are used as the material for FPCs. Plastic films are used for moving parts of electronic devices because of their flexibility and bendability. - Light in Weight

FPCs are made of plastic and are lightweight. This is a necessity in the space and aviation industries, where weight restrictions are strict. - Expensive

FPCs tend to be more expensive than rigid boards, which are regular printed circuit boards.

2. Points to note when using FPCs

There are two major points to note when using FPCs.

- Difference in Bending Resistance

FPCs are characterized by high flexibility, but their flex resistance differs among manufacturers and products. - Mechanical Weakness

FPCs are light and thin films, making them mechanically weak. When mounting components, a plate called a reinforcing plate must be attached to the electronic components.

FPCs must be used in consideration of the above points.

3. Increase in the Size of the FPC Market

According to a study by Credence Research, the global FPC market is increasing year by year; it is projected to grow at a CAGR of 10.6% from 2018 to 2027, and the global market size for flexible electronics is expected to grow to approximately 4.5 trillion yen by 2027.

The growing market is related to the rising demand for FPCs in the automotive, consumer electronics, and aerospace industries.

List of 50 FPC Manufacturers

*Including some distributors, etc.

Sort by Features

- Default

- Company Size: largest first

- Year Founded: oldest first

- Year Founded: earliest first

Sort by Area

- United States of America

- Austria

- Canada

- China

- Denmark

- Germany

- Japan

- Poland

- Singapore

- Switzerland

- Taiwan

- United Kingdom

-

-

-

The Hall Co.

Flexible Film Printed Circuit

Manufacturer Overview

The Hall Company, founded in 1961 and based in Urbana, Ohio, U.S.A., is a manufacturer of sensors and electronic devices for various industries. The company's product folio includes collision sensors, membrane switches, graphic overlays, capacitive switches, and, identification products that have a wide range of applications in medical, aviation, food equipment, appliances, and industrial equipment manufacturing sectors. The company also provides product design assistance, flexible circuit component placement, screen printing, and, laser cutting services. The company has the equipment and expertise to print on top of covers and thicker materials, such as product bezels.

-

-

-

-

-

DuPont Teijin Films

Flexible Circuits

Manufacturer Overview

DuPont Teijin Films, established in 2000 as a global joint venture between DuPont de Nemours, Inc., and Teijin Limited, is a manufacturer headquartered in Chester, Virginia with an office in Chuo-ku, Tokyo, specializing in polyethylene terephthalate (PET) and polyethylene naphthalate (PEN) polyester films. The company’s polyester films are offered under brands like Kaladex, Melinex, and Mylar. They are utilized in industries like construction, electrical components, photovoltaics, and healthcare. Additionally, these films are used in printing and packaging, particularly food packaging for various markets like bakery, chilled ready meals, fresh-cut produce, frozen food, and protein, along with cap liners for induction sealing.

-

-

-

-

-

San Francisco Circuits, Inc.

FLEX PCB

Manufacturer Overview

San Francisco Circuits, Inc., established in 2005, is a service provider and manufacturer of printed circuit board fabrication based in San Mateo and San Diego, California, USA. The company offers borderless boards through an extensive network of partners ranging from intricate production quantities to prototype PCBs with fast turnaround times and turnkey PCB assembly. The company specializes in various PCB types, including prototypes, Mil Spec PCBs, multi-layer PCBs, and many more. Covering IPC Class 1, 2, 3, and Mil Spec Boards, the company has small to medium production runs in compliance with industry standards like RoHS and WEEE.

-

-

-

-

-

Sheldahl Corporation

Flexible printed circuit FPC solutions

Manufacturer Overview

Sheldahl Corporation, founded in 1955 and headquartered in Northfield, United States, is a manufacturer of custom materials and flexible printed circuits. The company designs custom solutions such as, flexible printed circuits, thermal control materials and industrial abrasive materials that fit the customer's needs. It has worked on creating the heat shield material for the James Webb telescope, and engineering the first flexible circuit for the automotive industry. It develops these technologies for a range of other industries including, architectural lighting, healthcare and human-machine interface. The company has obtained many certifications for its quality management system, which includes ISO 14001:2015 and IATF 16949:2016.

-

-

-

-

-

Millennium Circuits Limited

FLEXIBLE PCBS

Manufacturer Overview

Millennium Circuits Ltd, founded in 2005, based in Pennsylvania, United States, is a manufacturer and supplier of PCBs. Their product portfolio includes printed aluminum and ceramic PCBs circuit boards, and SMT stencils. The company also offers a range of PCB solutions with the cutting-edge technology of high-frequency laminate, microwave circuits, good quality control, technical support, and ISO certifications. The products have multiple applications in medical instrumentation, test, and measurement, LED lighting, automotive, consumer electronics, marine, and industrial equipment, as well as electronic and manufacturing industries.

-

-

-

-

-

Molex, LLC

Flexible Printed Circuit (FPC) Solutions

Manufacturer Overview

Molex was founded in 1938 with the invention of Molex in 1938 and today is headquartered in Lisle, Illinois, and a subsidiary of Koch Industries. In the 1950s, the company invented the Molex connector which became the standard for power connections in personal computers for decades. Today the company is a manufacturer of electronic and fiber optic connectivity systems for customers in industries such as automotive, consumer electronics, healthcare, manufacturing, and telecom infrastructure. The company has several product categories including Connectors, Optical Solutions, Capillary Tubing & Micro Components, and Automation.

-

-

-

-

-

Flexible Circuit

Flexible Printed Circuits

Manufacturer Overview

Flexible Circuit, established in 2000 and based in Minneapolis, United States, is a manufacturer of flex-printed circuits, and circuit assemblies. The company also and designs and provides EV Battery monitoring solutions. The company-made battery monitoring solutions are used in different vehicles, including automotive, recreational, tools and equipment. The company supports the design, prototyping and production of EV batteries. The company has set up a manufacturing facility in Zhuhai to manufacture high-density printed circuit boards such as FPC, Rigid Flex, flexible heaters and SLPs.

-

-

-

-

-

-

-

-

-

-

-

-

MADPCB

FLEXIBLE PRINTED CIRCUIT

Manufacturer Overview

MADPCB, established in 2004, and based in Shenzhen, China, is a supplier of PCB materials and services. The product portfolio includes a full range of PCB materials and services to fit all the demands of the Printed Circuit Board. The company offers extensive PCB services with technology which includes bare PCB fabrication, assembly, parts, IC programs, design services, and functional quality tests done under one roof. The company is recognized as a one-stop solution Electronic Contract Manufacturer for PCB services.

-

-

-

-

-

OKI Circuit Technology Co.,Ltd.

Flex-Rigid PCB

Manufacturer Overview

OKI Circuit Technology Co., Ltd. is a Japanese manufacturer of printed circuit boards (PCBs) and electronic components established in 2012 and based in Tsuruoka, Yamagata. The company produces various PCBs that are able to manage high frequencies, radiation levels, currents, and speeds. These are used in automotive components, consumer electronics, medical equipment, and communication devices. Aside from its products, the company also offers custom design and testing services for customers with unique project requirements.

-

-

-

-

-

Shenzhen Kinwong Electronic Co.,Ltd.

Flexible PCBs

Manufacturer Overview

Shenzhen Kinwong Electronic Co., Ltd., established in 1993 and headquartered in Shenzhen, China, is a manufacturer that specializes in the development and production of printed circuit boards. The company offers a range of products, including conventional PCBs, flexible PCBs, RF PCBs, rigid-flex PCBs, and metal-base PCBs. It also offers engineering and design services to support customers in the development of its electronic products. Its products are used in applications where space is limited and high reliability is required. The company has achieved ISO9001:2015 and IATF16949:2016 certifications. It serves industries such as automotive, medical devices, aerospace, IoT, energy, and more.

-

-

-

-

-

iPCB Circuits Limited

FLEX PCB

Manufacturer Overview

iPCB Circuits Limited, established in 2017, is an exporter, manufacturer, and fabricator of printed circuit boards based in Shenzhen, Guangdong, China. The company’s product line includes high-precision multilayer PCB, high-frequency PCB, microwave circuit board, rigid-flex PCB, and HDI PCB board. It also offers PCB design, PCBA assembly services, PCB samples, small batch production, and stable production of large quantities of the PCB. Its products are used in communications circuits, industrial control circuit boards, rail transit PCB boards, medical electronics PCBs, and automotive electronics PCBs. It supplies its products to more than 60 worldwide countries.

-

-

-

-

-

PCBCart

Flexible PCB

Manufacturer Overview

PCBCart, established in 1986 with headquarters in China and numerous facilities across China, is a manufacturer of printed circuit boards and a provider of PCB assembly services. The company's product line includes the custom PCB manufacture of rigid PCBs, flex PCBs, MCPCBs, and Rogers PCBs. PCBCart's products are used across industries for the production of consumer products, home appliances, automotive electronics, and telecommunications infrastructure. The company also offers turnkey PCB assembly services to meet custom THT, SMT, PoP, and other assembly requirements.

-

-

-

-

Manufacturer Overview

AT&S, a German-based company founded in 1987 and headquartered in Leoben, Austria, is a manufacturer of printed circuit boards (PCBs) and innovative interconnect solutions. With their state-of-the-art facilities and advanced technology, AT&S produces a wide range of printed circuit boards for various industries, including automotive, industrial, and telecommunications. Their products are utilized in electronic devices and systems, providing essential connectivity and functionality. The company also offers comprehensive support to its customers throughout the entire process, from initial inquiries to post-sales assistance. Their customer services include prompt and responsive communication, technical support, and consultation to address any issues or concerns.

-

-

-

-

-

Cicor Group

Flexible printed circuit boards

Manufacturer Overview

Cicor Group, established in 1966 and headquartered in Bronschhofen, Switzerland, is a manufacturer of household appliances, electrical equipment, and electronics. The company offers a wide range of products and services in the field of electronic solutions, including printed circuit board assembly, system assembly and box building, switchgear cabinet construction, cable assembly, and more. It also offers tool design and fabrication, plastic injection molding, and medical devices. Its products are used to control electrical equipment in industrial settings. The company has achieved ISO 9001 and ISO 14001 certification. It serves a range of industries, including medical, industrial, aerospace, and defense.

-

-

-

-

-

ES&S Solutions GmbH

Transparent flexible printed circuits

Manufacturer Overview

ES&S Solutions GmbH was established in 1990 in Viersen-Mackenstein, Germany and is a manufacturer of electronics components. The company's products include adapters, PCB, flex jumpers, cables and wires, which are used in electronics and electrical applications. It has some accreditations, including RoHS, ISO 9001:2015, Reach and UL. In case of any fault, the company has a return structure where customers fill out a Return Material Authorisation (RMA) form on the website. Also, it provides a contact person for clients to give them advice on technical matters.

-

-

-

-

-

Yamaichi Electronics Co., Ltd

High-speed transmission FPC

Manufacturer Overview

Yamaichi Electronics Co., Ltd was founded in 1956 and is a manufacturer of test solution and connector solution products based in Ota, Tokyo, Japan. The company manufactures various products such as open top burn-in sockets, cantilever test sockets, camera module connectore, high speed transmission wiring board, and card edge sockets. The products are used in various applications such as automobiles, production sites, communications infrastructure, smartphones, and servers. The company has certified with ISO 9001 and ISO 14001 standards certifications.

-

-

-

-

-

HIROSE ELECTRIC CO., LTD.

FPC/FFC

Manufacturer Overview

HIROSE ELECTRIC CO., LTD. (HRS) is a Japanese manufacturer specializing in electronic and electrical connectors. Founded in Tokyo in 1937, the company now has eight factories located in Japan, China, Korea, Malaysia, and Indonesia, with several sales and service locations throughout the US, Europe, and Singapore. The company carries a selection of over 50,000 products, including fiber optic connectors, sealed connectors, and card edge connectors. HRS also offers advanced engineering services to cater to specific customer demands, and after-sales support to clients in the consumer electronics, automotive, and telecommunications industries.

-

-

-

-

-

TATSUTA Electric Wire and Cable Co.,Ltd.

EMI shielding film

Manufacturer Overview

Tatsuta Electric Wire and Cable Co. Ltd., established in 1945 and headquartered in Higashiosaka, Japan, is a manufacturer of electric wires, electronic materials, medical products, and sensors. The company began manufacturing and selling telecommunication wires and cables in 1955. In 1981, it started manufacturing water leakage detection systems, and in 1984, it began selling bonding wire. Its telecommunications division received ISO 9001 certification in 1996, and the electric wire and cable division in 1998. The company began the production of EMI shielding film in 2003, and its product portfolio includes broadcasting cables, bonding wires, liquid leakage sensors, and functional paste.

-

-

-

-

-

Canon Components, Inc.

TAB Flexible Board

Manufacturer Overview

Canon Components, Inc., established in 1984 and headquartered in Saitama, Japan, is a manufacturer and supplier specializing in optical, imaging, and industrial products. The company’s product portfolio includes printed wiring boards, contact image sensors (CIS), medical equipment, and ink cartridges and ink tanks. These products are utilized by various sectors, including consumer electronics, industrial automation, printing and imaging, scientific research, and healthcare and medical. The company is expanding its network both locally and internationally, with production bases in Vietnam and Thailand.

-

-

-

-

-

Meiko Electronics Co., Ltd.

FPC

Manufacturer Overview

Meiko Corporation is a Japanese company headquartered in Ayase, Kanagawa Prefecture. The company designs and manufactures printed circuit boards primarily for the automotive and telecommunications industries, as well as for home appliances, medical equipment, and robotics. Meiko designs advanced PCBs and related parts and offers comprehensive electronic manufacturing services (EMS) for electronics. EMS services cover each step from pattern design (CAD) through tool inspection, assembly, and quality inspection. Meiko is the largest manufacturer of circuit boards specializing in cellular phone and automative markets.

-

-

-

-

-

Taiyo Kogyo

FPC Product Lineup

Manufacturer Overview

Taiyo Kogyo is a manufacturer of tensile membrane structures and equipment established in 1946 and based in Osaka, Japan. The company offers tensile membrane (TM) tent warehouses for temporary storage applications, TM truss space frame systems for structures spanning larger areas, and TM tarpaulins for material quality preservation during transport or freight operations. It also offers TM-fabricated materials for construction projects, including canopies and film partitions. The company’s products are commonly used in the logistics, civil engineering, and construction industries.

-

-

-

-

-

Toshiba Hokuto Electronic Corporation

Flexible Printed Circuit Board

Manufacturer Overview

Toshiba Hokuto Electronic Corporation, established in 1950 and headquartered in Tokyo, Japan, is a pumps, valves, and manufacturing recycling equipment wholesale distributor. The company's products include thermal print heads, flexible printed circuit boards, magnetrons for microwave ovens, and industrial applications. These products are used in fine printing machines, electronic phones, computers, and other small handheld electronics; plasma processing in the manufacture of semiconductors; and industrial dielectric heating applications. The company offers R&D services to provide customer support, including the development of new technologies and products and on-time delivery.

-

-

-

-

-

Oki Electric Cable Co.,Ltd.

FPC

Manufacturer Overview

Oki Electric Cable Co.,Ltd. was established in 1936 and is a manufacturer of telecommunications instrument based in Isesaki, Gunma, Japan. The company produces various communications devices such as high speed interface cables, wire harnesses, EDM wire, optical cables, and OKI cables. The products have been applied in various industries such as robotic, automobile, semiconductor manufacture, medical, and financial sectors. The company also involved in real estate business as one of the four major business operations.

-

-

-

-

-

NIPPON MEKTRON, LTD.

Multi-layer FPC FLEXBOARD

Manufacturer Overview

NIPPON MEKTRON, LTD. established in 1969 and based in Tokyo, Japan, is a manufacturer and supplier of electronic products. The company's product range includes single-sided FPC, double-sided FPC, multi-layer FPC (FLEXBOARD), component assembly FPC, and high-speed transmission FPC. These products are used in automotive components, wearable devices, robotics, and precision parts for both mobile devices and HDDs. It serves industries such as electronics, automotive, robotics, and mobile device manufacturing. For its customers, the company provides services like research and development, manufacturing, sales, and after-sales support.

-

-

-

-

-

Sumitomo Electric Printed Circuits, Inc.

Ultra-soft FPC

Manufacturer Overview

Sumitomo Electric Printed Circuits, Inc., established in 1983 and located in Koka City, Japan, is a manufacturer that specializes in printed circuits. The company offers a wide range of flexible printed circuits such as Highly Flexible FPC, Ultra-soft FPC, Shape Keeping FPC, and more. It also offers heat-shrinkable tubing, nickel alloy, cladded/plated wire, spiral-shielded wires, and coaxial cables. Its products are adaptable in forming high-density circuits in a small area, making them suitable for use in smartphones, digital cameras, and other advanced devices. The company has sponsored the Shiga Prefecture Para-Sports Association. It serves the automotive, electronics, and telecommunications industries.

-

-

-

-

-

Mektec

Flexible Printed Circuits

Manufacturer Overview

Mektec Corporation, founded in 1961 and based in Weinheim, Baden-Württemberg, Germany, is a manufacturer of flexible printed circuit boards. The company belongs to Mektron Corporation in Japan and operates in Asia, America and Europe. The company supplies its products to the telecommunication and automotive industries. The company designs printed circuit boards that fit in complex 3D structures or assembly spaces. The company also offers soldering techniques to add components to the FPC boards. The company boards are thin and use sealing technologies to protect sensitive components and electrical interfaces.

-

-

-

-

-

Agile Circuit Co., Ltd

FLEXIBLE FPC

Company Overview

Agile Circuit Co., Ltd, Established in 2003, stands as a manufacturer and supplier of printed circuit boards (PCBs). The company excel in delivering a wide array of PCB solutions, including rigid (116 layers), flex (16 layers), and rigid-flex circuits (1~6 layers). The company is well-equipped to meet your needs, whether the requirement is for quick-turn prototypes, short-run projects, or high-volume mass production. The company's customer-centric approach ensures the quality, cost-effective PCB boards for various applications, spanning computer technology, telecommunications, consumer electronics, automotive systems, and industrial applications.

-

-

-

-

-

Mekoprint

Flexible printed circuits

Company Overview

Mekoprint, founded in 1954 and based in Stovring, Denmark, is an ISO 9001 certified manufacturer and supplier of solutions for industrial and electronics companies. The company designs and provides comprehensive solutions in the areas of printed electronics, cable harnesses, metal components, precision solutions, and graphic solutions. These products find various applications in green tech, automation, medical, professional equipment, and household appliances. Approximately 500 people work for the firm at its 40,000-square-meter European production facilities.

-

-

-

-

-

McNika

Flexible printed circuit FPC

Company Overview

McNika, founded in 1972 and headquartered in Shin-Yokohama, Kohoku-ku, Yokohama, is a manufacturer and supplier of electronic components, specializing in semiconductors and integrated circuits. The company offers a wide range of product portfolios including, integrated circuits such as PLDs, and ASICs, analog ICs, electronic devices, network-related software, and hardware. These cutting-edge components cater to diverse industries and applications including consumer electronics for memory and control functions, communication systems for optimizing performance and power efficiency, automotive for safety and navigation systems, and medical devices such as MRI, pacemakers, and glucose monitors.

-

-

-

-

-

NOK CORPORATION

Flexible printed circuit technology

Company Overview

Nok Corporation, founded in 1941 and based in Tokyo, Japan, is a manufacturer of several products, including sealing, rubber, and electronic products, and is part of the NOK Group. The company also makes flexible printed circuits (FPC), office automation equipment, and functional membranes, serving industries such as automobile, construction machinery, and electronic equipment. In 1960, the company expanded its production by constructing plants in Kumamoto, Fujisawa, and Shizuoka, and it was listed on the Tokyo Stock Exchange in 1961. In 1979, it was the first to set up a production base in the US before any Japanese automaker.

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

MULTI-TEKNIK PCB group AB

Flexible PCB

-

-

-

-

-

MIKASA SHOJI CO.,LTD.

FPC (Flexible Printed Circuits)

Distributor Overview

MIKASA SHOJI CO., LTD. established in September 1948 and headquartered in Osaka, Japan, is a manufacturer and supplier of various electric products. The company's product range includes Primary and Secondary batteries, Mobile PC peripherals for business use, HDD/SSD/ODD storage solutions, Microcomputers, and Custom ICs. These products support functions in the electronics, automotive, and information technology sectors. In addition, it engages in the production and sale of medical supplies and health appliances. It also delves into the fields of software and hardware development and offers internet-based information and retail services.

-

-

-

-

-

Multi Circuit Boards Ltd.

Flexible circuit boards

Distributor Overview

Multi Circuit Boards, established in 2012 and located in Holyrood Close, Poole, is a supplier of printed circuit boards and multilayer boards. The company supplies business customers with printed circuit board prototypes and series of up to 48 layers for the tightest spaces or multiple bending cycles. It also offers rigid-flex circuit boards, laser-cut SMD stencils for the assembly of SMD components, and toroidal transformers with variable power and voltage. It offers customized solutions to meet customer-specific requirements and distributes its products worldwide to more than 50 countries.

-

-

-

-

-

PCB Connect

FLEXIBLE PCBs

Distributor Overview

PCB Connect, founded in 2004, and headquartered in Stockholm, Järfälla, Sweden, is a distributor and supplier of Printed Circuit Boards. The company offers a range of PCBs, including single-sided PCBs for basic circuits, double-sided PCBs for more complex setups, and multilayer PCBs for intricate electronics. Rigid PCBs for applications with vibrations and flexible PCBs for bending needs are also provided. These products cater to industries like automotive, aerospace, medical, industrial, and consumer electronics, offering solutions for electronic circuit requirements.

-

-

FPC Manufacturer Ranking

*Including some distributors, etc.Ranking as of April 2024

Derivation Method| Rank | Company | Click Share |

|---|---|---|

| 1 | Millennium Circuits Limited |

5.7%

|

| 2 | MADPCB |

3.9%

|

| 3 | Molex, LLC |

3.9%

|

| 4 | King Epoxy Emblem Co., Ltd |

3.6%

|

| 5 | The Hall Co. |

3.3%

|

| 6 | San Francisco Circuits, Inc. |

3.3%

|

| 7 | PFC Flexible Circuits Limited |

3.0%

|

| 8 | MFLEX |

3.0%

|

| 9 | Telamco, Inc. |

2.7%

|

| 10 | Sheldahl Corporation |

2.7%

|

Derivation Method

The ranking is calculated based on the click share within the fpc page as of April 2024. Click share is defined as the total number of clicks for all companies during the period divided by the number of clicks for each company.Number of Employees

- Meiko Electronics Co., Ltd.: 12,337

- HIROSE ELECTRIC CO., LTD.: 5,070

- TATSUTA Electric Wire and Cable Co.,Ltd.: 1,011

Newly Established Company

- Best Technology Co., Ltd.: 2013 (11 years ago)

- InterElcom Sp. z o.o.: 2011 (13 years ago)

- San Francisco Circuits, Inc.: 2005 (19 years ago)

Company with a History

- HIROSE ELECTRIC CO., LTD.: 1937 (87 years ago)

- TATSUTA Electric Wire and Cable Co.,Ltd.: 1945 (79 years ago)

- MIKASA SHOJI CO.,LTD.: 1948 (76 years ago)

FPC Manufacturers in United States

*Including some distributors, etc.

- The Hall Co.

- DuPont Teijin Films

- San Francisco Circuits, Inc.

- Sheldahl Corporation

- Millennium Circuits Limited

- Molex, LLC

- Flexible Circuit

- Telamco, Inc.

- King Epoxy Emblem Co., Ltd

- MFLEX

- All Flex

Global Distribution of FPC Manufacturers by Country

*Including some distributors, etc.

| Country | Number of Companies | Share (%) |

|---|---|---|

United States of America

United States of America

|

11 | 28.2% |

China

China

|

8 | 20.5% |

Japan

Japan

|

7 | 17.9% |

Germany

Germany

|

3 | 7.7% |

Switzerland

Switzerland

|

2 | 5.1% |

Taiwan

Taiwan

|

2 | 5.1% |

Austria

Austria

|

1 | 2.6% |

Denmark

Denmark

|

1 | 2.6% |

Poland

Poland

|

1 | 2.6% |

United Kingdom

United Kingdom

|

1 | 2.6% |

Singapore

Singapore

|

1 | 2.6% |

Canada

Canada

|

1 | 2.6% |

List of FPC Products

33 products are listed.

Maruwa Seisakusho Co., Ltd.

Build -up method is also possible in addition to normal laminating methods, multilayer FPC standard specifications

10+ people viewing

■ Overview The conductor is a print wiring board with three or more layers. Build -up methods are also possible besides normal laminate constructio...

Maruwa Seisakusho Co., Ltd.

Double -sided FPC standard specifications can be conducted on both sides by squall plating

10+ people viewing

■ Overview It is a print wiring board with a conductor pattern on both sides, centered on the base film (insulated substrate). Print wiring plate w...

Maruwa Seisakusho Co., Ltd.

Effective use of free bending and embedded space can be used one -sided FPC standard specification

10+ people viewing

■ Overview It is a print wiring board with a conductor pattern only on one side. It is possible to use the free bending and embedded space effectiv...

Maruwa Seisakusho Co., Ltd.

Free bending and embedded space can be effective one -sided FPC Fine pitch specification

10+ people viewing

■ Overview It is a print wiring board with a conductor pattern only on one side. It is possible to use the free bending and embedded space effectiv...

Maruwa Seisakusho Co., Ltd.

Highly heat -driven high heat dissipation FPC new structure for FPC equipped with LED

10+ people viewing

■ Characteristics ・ LED and joining temperature can be reduced by 10%or less. ・ Extend the life of LEDs by about 10%to 20%. ・ It is realized at ...

Maruwa Seisakusho Co., Ltd.

Imported dance control can be impedance control FPC

10+ people viewing

■ Overview Import dance control is possible by high -precision pattern formation technology.

Maruwa Seisakusho Co., Ltd.

Build -up method is also possible in addition to normal laminating methods, multilayer FPC Fine pitch specifications

■ Overview The conductor is a print wiring board with three or more layers. Build -up methods are also possible besides normal laminate constructio...

Matsuwa Sangyo

Flexible board (FPC)

10+ people viewing

It has been about 30 years since I continued to make a rigid substrate. Many customers have begun manufacturing in response to the request of "I wa...

Maruwa Seisakusho Co., Ltd.

Reflow reflective rate 90% BLK (high reflection FPC)

10+ people viewing

■ Overview ・ Reflow reflective rate 90% ・ Lightness is 10%up without changing the existing module design (reduced cost) ■ Characteristics (exper...

Maruwa Seisakusho Co., Ltd.

Variation corresponding to hypo rebellious needs Low -resilience FPC MK series

10+ people viewing

■ Overview The lineup of the thin FPC brand "MK Series" has been renewed and a variety of variations that meet the needs of low -rebound is availab...

Maruwa Seisakusho Co., Ltd.

Double -sided FPC Fine pitch specifications can be conducted on both sides by squall plating

■ Overview It is a print wiring board with a conductor pattern on both sides, centered on the base film (insulated substrate). Print wiring plate w...

Maruwa Seisakusho Co., Ltd.

Highly heat -dissipated FPC with LED -mounted FPC conventional structure

40+ people viewing

■ Characteristics ・ LED and joining temperature can be reduced by 10%or less. ・ Extend the life of LEDs by about 10%to 20%. ・ It is realized at ...

Maruwa Seisakusho Co., Ltd.

Shield structure for high -frequency signal high -speed transmission and noise measures Shield structural print wiring plate electromagnetic wave shield FPC Multi -layered FPC

10+ people viewing

■ Overview It is a print wiring board with a shield structure for high -speed transmission and noise measures at all high -frequency signals. In ad...

Maruwa Seisakusho Co., Ltd.

Environmentally friendly FPC development halogen -free FPC

■ Overview Materials that contain chlorine (CL) and bromin (BR) may cause harmful dioxin when burned. We are working on environmentally friendly FP...